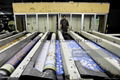

CH21/30DNC Computer Control Copy Warping Machine

Technical parameters:

Line Speed 0~1000m/min

Max. Tension of line 500N

Brake Torque 1600NM

Up and Down of Beam Pneumatic control

Tight and release of Beam Pneumatic control

Diameter of Speed Roller 120mm

Power of Main Motor 7.5kw

Control type of Main Motor Converter Control

Monitoring Way

Immediate monitor by Microcomputer

controlled touch screen

Control type of Positive Yarn-send Roller 3kw AC high-speed servo control and

active let off roller control mode

Diameter of Positive Yarn-send Roller 100mm

Pressure of Pneumatic source 6bar

CH21/30DNC copy warping machine is suitable for Φ30”×21”and Φ21”×21”

beams.

Main configuration:

Main Motor SIEMENS OF GERMANY

High-speed servo system TECO OF TAIWAN

Converter EMERSON OF USA

Test components A AUTONICS OF SOUTH KOREA

Test components B KOYO OF JAPAN

Pneumatic components AIRTAC OF TAIWAN

PLC OMRON OF JAPAN

Touch screen MCGS OF BEIJING

Operating components SCHNEIDER OF FRANCE

Terminal components PHOENIXCONTACT OF GERMANY

Bearings NSK OF JAPAN Technical specification:

◆ The special copy function guarantees the data of every beam are the samein the same

group, like the circle number, meters and diameter. This function avoids that the yarn

quantity is not unique caused by different diameters, which canreduce the waste of yarn.

◆ The main motor is controlled by converter. The constant and reliable digital pulse close

ring controlled by the PLC guarantees the speed of winding and storing yarn is stable.

◆ The bracket movement of beam is controlled by pneumatic, and its position is accuracy

controlled by photoelectric sensor and the PLC automatically, which select the different

position according to beam's diameter.

◆ The tail bracket is controlled by pneumatic, and the shaft adepts centre fixing shaft head.

These two features make the damage to inner beam caused by the shift lower down to the

minimum.

◆ The main brake adepts pneumatic butterfly brake. The breakingtray with middle

unoccupied has a nice heat-dissipated function. On the other hand, the using of break

pincer with auto-compensation and the hoofed piece makes the butterfly brake stable and

last a long life.

◆ The brake of Positive roller and Speed roller can make different brake pressures

according to different speeds (more than 200 m/min). These different pressures, together

with the main beam break, guarantees the yarn tension in the breaking time is the same as

the tension under the constant speed.

◆ The electric parts adept the programmable controller of CP1H seriesof OMRON and 7”

MCGS touch screen of Beijing. All the electrical troubles and wrong operation

information are displayed on the screen, in which the Chinese language and English

language can be exchanged according to different requirement. The pneumatic part, Aortic,

is made in Taiwan. Their soft air media finishes all the activities required by mechanical

parts according to correct orders from the PLC.

◆ The Positive roller is covered by high-hardness coating, so the smoother surface

improves the absorption to the yarn. The AC high-speed servo system provides a power to

the above roller, matching with the PLC, both of which service for the main winding

system, to make sure the tension of yarn unique constantly.

◆ Remote deb ing can monitor the current working state and fault condition.