| Model: | PPR |

|---|---|

| Brand: | KAIDE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | PPR pipe machine , ppr pipe making , pipe making machine |

| Price: |

US $40000

/ pc

|

| Min. Order: | 1 pc |

Product Description

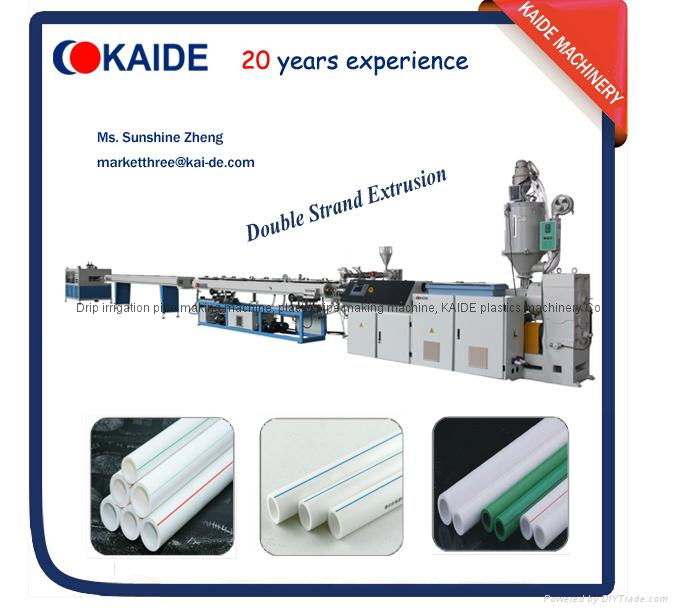

High Speed PPR Pipe Production Line

KAIDE factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe line and multi-layer composite pipe line. The PPR pipe line technology has been optimized based on our years experience, which speed can be reach to 28m/min, with most advanced technology.

Technical Parameters:

|

Line Model |

Screw Diameter |

L/D |

Production Scope |

Production Speed |

Nominal Power |

|

SJ-80 |

Ф80mm |

33:1 |

ф20-63mm |

28m/min |

178KW |

|

SJ-80 |

Ф80mm |

33:1 |

ф20-63mm |

20m/min |

186KW |

|

SJ-65 |

ф65mm |

33:1 |

ф20-63mm |

15m/min |

119KW |

Main Features of the line:

1) EXTRUDER: It adopts the specialized high efficient five-section type screw, which is our company independent design with completely independent intellectual property right, ensuring the rapid plasticizing dispersion effect, and realizing the high speed production.

2) GRAVIMETER: Equipped with high precise control system of pipe weight per meter, which is used for measuring & calculating and precise control of pipe weight per meter and its extrusion output, to realize the constancy of pipe weight and line running according to set parameters. The application of this system can shorten the start-up time and improve the produced pipe quality, and save raw material.

3) DIE HEAD: Special designed spiral pressure-storage die head effectively overcomes the instantaneous fluctuation of extrusion pressure, realizing high speed and constant pressure extrusion

of materials, which is the powerful guarantee to realize high speed and stable pipe production;

4) CALIBRATORS: Using our own proprietary multi-sheet water immersion type calibrator, to realized the effective and even cooling & calibrating of the pipe, and ensure the high speed production.

5) VACUUM CALIBRATING & COOLING TANK: Using high quality stainless steel; New designed cooling method, with water immersion for small size and spray cooling for big size, to achieve a better cooling effect.

6) HAUL-OFF MACHINE: High speed multi-group roller clamping & belt haul-off machine, Using imported frequency converter; the clamping force of any pitch can be adjusted freely, with high pulling speed and good stability.

7) CONTROL SYSTEM: Siemens PLC control system, to ensure the high precise & sync control and reliable running of the while production line.

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Weifang Kaide Plastics Machinery Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13805363035 |

| Contact: | Sunshine Zheng (sales engineer) |

| Last Online: | 18 Jun, 2021 |

Related Products of this Company

-

Inline flat drip irrigation tape

-

PE drip irrigation pipe making machine

US $30000

-

PERT pipe making machine KAIDE

US $40000

-

Cross-linking PEX Pipe Making Machine

US $40000

-

PEX/EVOH oxygen barrier pipe making

US $80000

-

Overlaop Welding PEX-AL-PEX Pipe

US $80000

-

PPR/Glass-fiber Pipe Production Machine

-

Inline flat drip irrigation tape

-

Overlap Welding PEX-AL-PEX Pipe Extruder

US $80000

-

PVC fiber hose making machine KAIDE