| Model: | ZE01 |

|---|---|

| Brand: | ZHUOER |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Power Transmission Equipment & Transformer |

| Label: | standard R reducer , hardened helical , helical rigidgearbox |

| Price: |

US $100

/ pc

|

| Min. Order: | 1 pc |

Product Description

Detailed Product Description

R Series Rigid Tooth Flank GearboxSpeed Reducer Helical Gear Reducer for Industry

1. Output speed: up to 1028 r/min

2. Output torque: up to 18000 N.m

3. Driving motor output: 0.12~160 kW

4. Frame range: R17~R167

5. Transmission Ratio: ≥3.83

6. Various mounting design: R, RF, RX, RXF

Characteristics

1. Helical gear motor is based on the building block design, so it’s convenient for them to fit all types of motors

or to connect with other power input. The same type of gearbox can fit motors with different power, so that it

is possible for different types of machines to combine or connect.

2. High transmission efficiency. A single machine can reach a transmission efficiency as much as 96%

3. Precise division of transmission ratio with a wide range. The combination of machines can produce a larger

transmission ratio at a low output rotational speed.

4. High performance, high safety factor, Low consumed energy, small vibration, low noise, high precision,

big torque and long working life.

Working Conditions

1. Working temperature: -40~50°C. the lubrication should be heated until about 0°C if the machine works

below 0°C.

2. The working place should be lower than 1,000 meters above sea level.

3. The input rotational speed should not exceed 1800 r/min. The circumferential speed of the gear should

not exceed 20 m/s.

4. Suitable for normal-reverse rotation.

5. Without industry limitation.

6. Please consult our technical supporting department for other circumstances.

Input power rating and permissible torque

|

Size |

17 |

27 |

37 |

47 |

57 |

67 |

77 |

87 |

97 |

107 |

137 |

147 |

167 |

|

Structure |

R RF |

||||||||||||

|

Input power rating(KW) |

0.18~0.75 |

0.18~3 |

0.18~3 |

0.18~5.5 |

0.18~7.5 |

0.18~7.5 |

0.18~11 |

0.55~18.5 |

0.55~30 |

2.2~45 |

5.5~55 |

11~90 |

11~160 |

|

Ratio |

3.83~74.84 |

3.37~135.09 |

3.33~134.82 |

3.83~176.88 |

4.39~186.89 |

4.29~199.81 |

5.21~195.24 |

5.36~246.54 |

4.49~289.74 |

5.06~249.16 |

5.15~222.60 |

5.00~163.31 |

10.24~229.71 |

|

Permissible torque(N.m) |

85 |

130 |

200 |

300 |

450 |

600 |

820 |

1550 |

3000 |

4300 |

8000 |

13000 |

18000 |

|

Size |

37 |

57 |

67 |

77 |

87 |

97 |

107 |

127 |

157 |

|

Structure |

RX RXF |

||||||||

|

Input power rating(KW) |

0.18~1.1 |

0.18~5.5 |

0.18~7.5 |

1.1~11 |

3~22 |

5.5~30 |

7.5~45 |

7.5~90 |

11~132 |

|

Ratio |

1.62~4.43 |

1.3~5.5 |

1.4~6.07 |

1.42~6.00 |

1.39~6.65 |

1.42~6.23 |

1.44~6.63 |

1.51~6.2 |

1.57~6.2 |

|

Permissible torque(N.m) |

20 |

70 |

135 |

215 |

400 |

600 |

830 |

1110 |

1680 |

Gear unit weight

|

Size |

R17 |

R27 |

R37 |

R47 |

R57 |

R67 |

R77 |

R87 |

R97 |

R107 |

R137 |

R147 |

R167 |

|

Weight(kg) |

4 |

5.5 |

8.5 |

10 |

18 |

25 |

36 |

63 |

101 |

153 |

220 |

400 |

700 |

|

Gear unit type |

RX37 |

RX57 |

RX67 |

RX77 |

RX87 |

RX97 |

RX107 |

RX127 |

RX157 |

|

|

|

|

|

Weight(kg) |

5 |

8 |

14 |

23 |

39 |

70 |

100 |

150 |

250 |

|

|

|

|

Ratio Everage and Maximum Torque

|

Model(acyclic) |

57 |

67 |

77 |

87 |

97 |

107 |

|

Structure |

RX RXF |

|||||

|

Ratio |

1.30-5.50 |

1.40-6.07 |

1.42-8.0 |

1.39-8.65 |

1.42-8.23 |

1.44-6.63 |

|

Maximum Torque(N·m) |

70 |

135 |

215 |

400 |

600 |

830 |

|

Model |

27 |

37 |

47 |

57 |

67 |

77 |

87 |

97 |

107 |

137 |

147 |

167 |

|

|

Structure |

R RF |

||||||||||||

|

Ratio |

3.37-135.09 |

3.41-134.82 |

3.83-176.88 |

4.39-199.81 |

4.29-199.81 |

5.31-246.54 |

5.30-246.54 |

4.5-251.15 |

4.92-251.15 |

5.15-222.8 |

5-163.31 |

10.24-229.71 |

|

|

Permission Torque(N·m) |

130 |

200 |

300 |

450 |

600 |

820 |

1550 |

3000 |

4300 |

8000 |

13000 |

18000 |

|

Lubricating oil scale

|

Model |

Lubricating oil scale(L) |

|||||

|

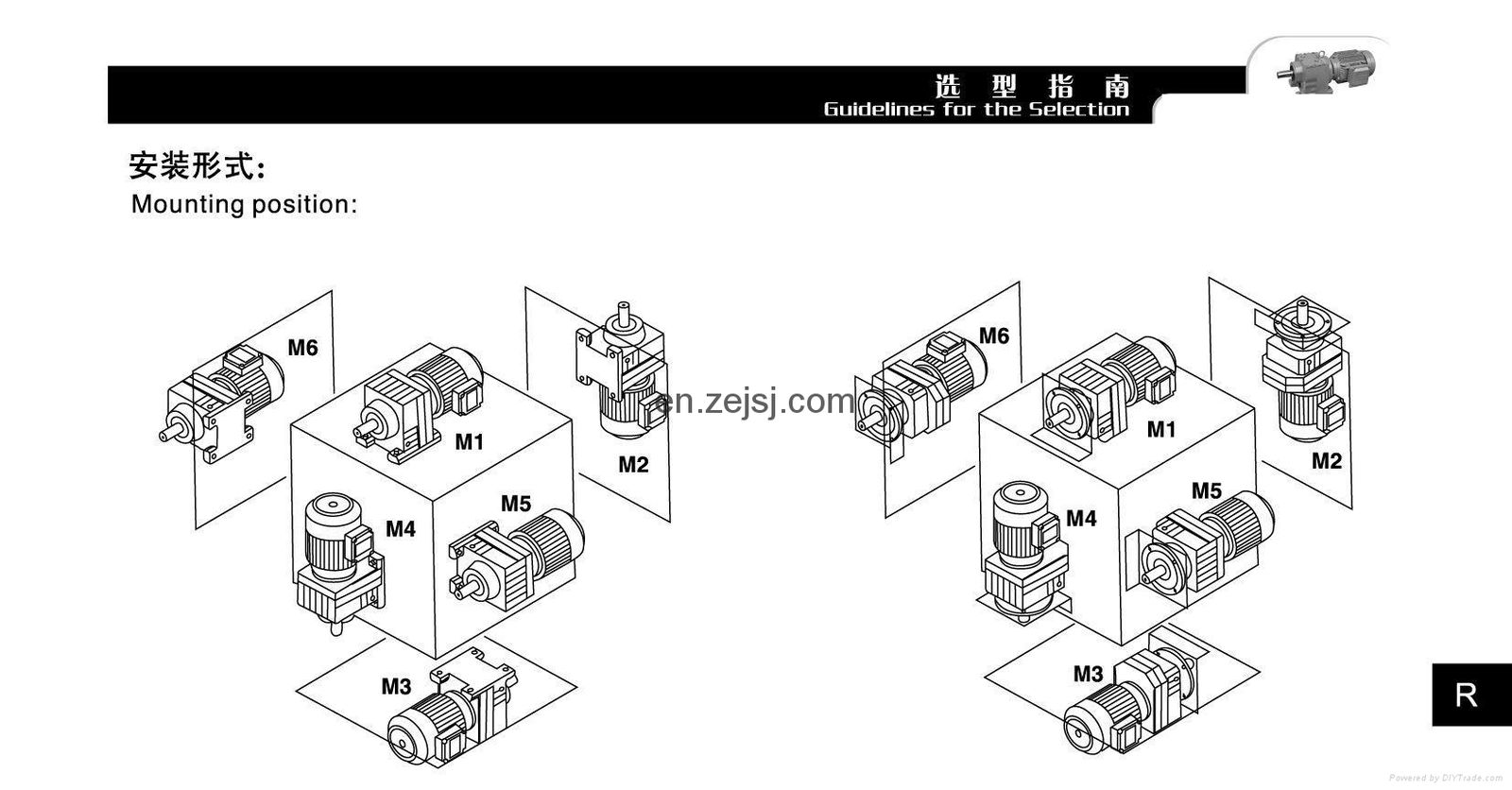

M1¹ |

M2¹ |

M3 |

M4c |

M5 |

M6 |

|

|

R27 |

0.25/0.4 |

0.7 |

0.4 |

0.7 |

0.4 |

0.4 |

|

R37 |

0.4/1 |

0.9 |

1 |

1.1 |

0.8 |

1 |

|

R47 |

0.75/1.5 |

1.6 |

1.5 |

1.7 |

1.5 |

1.5 |

|

R57 |

0.8/1.7 |

1.8 |

1.7 |

2 |

1.7 |

1.7 |

|

R67 |

1.2/2.5 |

2.7/3.6 |

2.7 |

3.1 |

1.9 |

2.1 |

|

R77 |

1.2/2.6 |

3.8/4.1 |

3.3 |

4.1 |

2.4 |

3 |

|

R87 |

2.4/6 |

6.8/7.9 |

7.1 |

7.7 |

6.3 |

6.4 |

|

R97 |

5.1/10.2 |

11.9/14 |

11.2 |

14 |

11.2 |

11.8 |

|

R107 |

6.3/14.9 |

15.9 |

17 |

19.2 |

13.1 |

15.9 |

|

R137 |

9.5/25 |

27 |

29 |

32.5 |

25 |

25 |

|

R147 |

16.4/42 |

47 |

48 |

52 |

42 |

42 |

|

R167 |

26/70 |

82 |

78 |

88 |

65 |

71 |

|

Model |

Lubricating oil scale(L) |

|||||

|

M1¹ |

M2¹ |

M3 |

M4 |

M5 |

M6 |

|

|

RX57/RXF57 |

0.6/0.5 |

0.8 |

1.3/1.1 |

1.3/1.1 |

0.9/0.7 |

0.9/0.7 |

|

RX67/RXF67 |

0.8/0.7 |

0.8 |

1.7/1.5 |

1.9/1.7 |

1.1/1 |

1.1/1 |

|

RX77/RXF77 |

1.1/0.9 |

1.5 |

2.6/2.4 |

2.7/2.5 |

1.6 |

1.6 |

|

RX87/RXF87 |

1.7/16 |

2.5 |

4.8/4.9 |

4.8/4.7 |

2.9 |

2.9 |

|

RX97/RXF97 |

2.1 |

3.4/3.6 |

7.4/7.1 |

7 |

4.8 |

4.8 |

|

RX107/RXF107 |

3.9/3.1 |

5.6/5.9 |

11.6/11.2 |

11.9/10.5 |

7.7/7.2 |

7.7/7.2 |

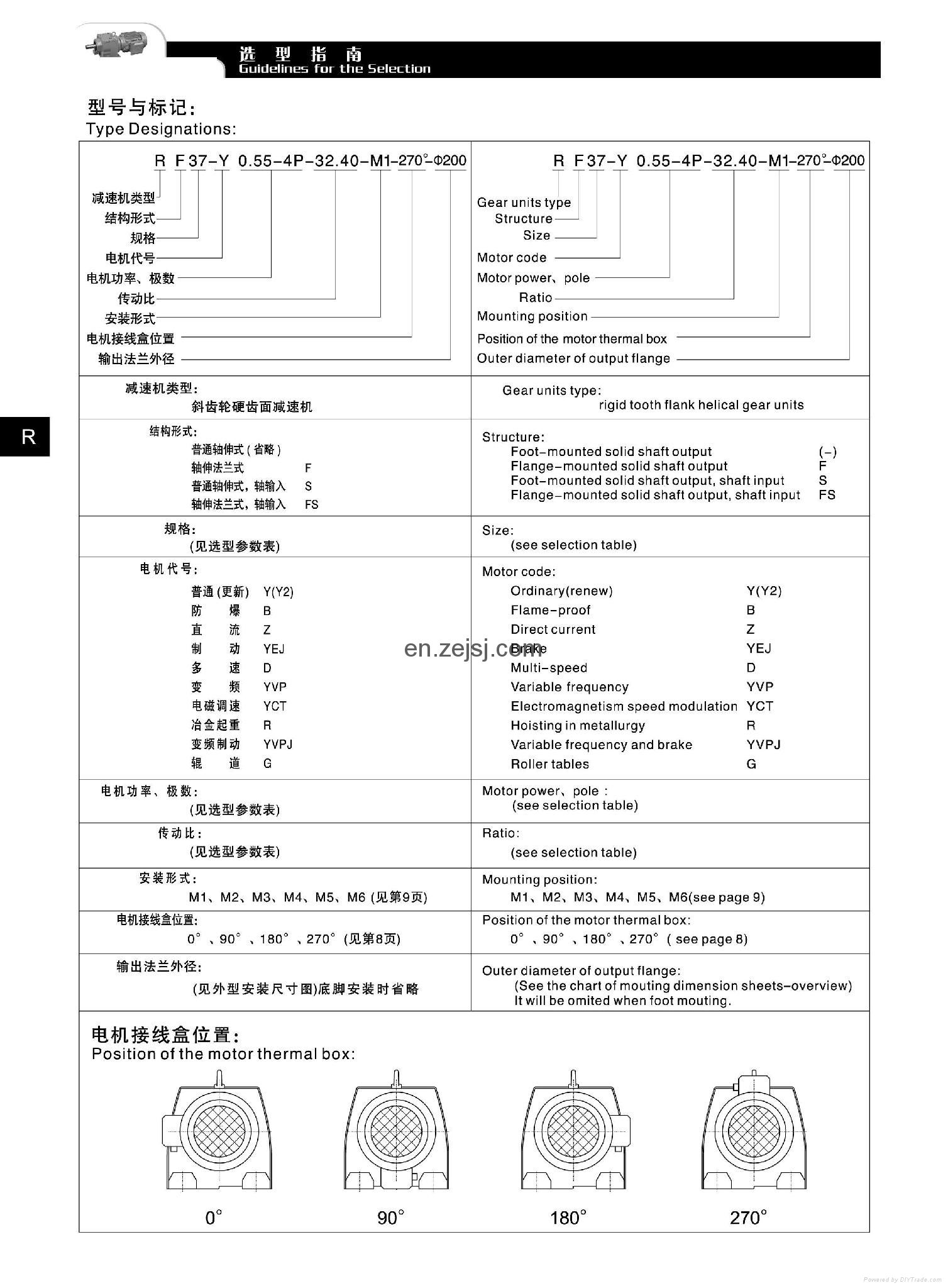

Reducer Models

R Series gear units are available in the following designs:

R…Y Foot-mounted helical gear units with solid shaft

RS Foot-mounted, shaft input helical gear units with shaft

R…R…Y Foot-mounted combinatorial helical gear units with solid shaft

R…RS Foot-mounted combinatorial, shaft input helical gear units with solid shaft

RF…Y Flange-mounted helical gear units with solid shaft

RFS Flange-mounted, shaft input helical gear units with solid shaft

RF…R…Y Flange-mounted combinatorial helical gear units with solid shaft

RF…RS Flange-mounted combinatorial, shaft input helical gear units with solid shaft

RM Specially for stirrer drives

R(RF、RX、RXF)…Y When equipping the users’ motor or the special one, the flange is required to be connected

RX…Y Foot-mounted single-stage helical gear units with solid shaft

RXF…Y Flange-mounted single-stage helical gear units with solid shaft

RXS Foot-mounted, shaft input single-stage helical gear units with solid shaft

RXFS Flange-mounted, shaft input single-stage helical gear units with solid shaft

After-sales Service

We attach great importance to pre-sales and after-sales service. Specific contents are as follows:

1. We provide detailed data so that our customers understand performance and application range of equipment; and for questions raised by the customers, we will truthfully answer them. No exaggerating the facts and no cheating the customers are our rules.

2. We meet the requirement of customers for inspecting our equipment. That is to say, the customers can make a visit

manufacturers who have used the equipment of the company and can appropriately modify or increase corresponding functions of the equipment according to requirements of the customers.

3. Before delivery of equipment, we guide the customers to operate the equipment and provide training for maintenance personnel.

4. After the equipment is delivered to work sites, we are responsible for installing and deb ing the equipment; and after normal running, the equipment is handed over to operation workers. Our technicians still stay in factories and leave th

factories until they ensure that production workers can skillfully operate the equipment.

5. After the equipment is delivered to the customers, we provide one-year warranty; and within warranty period,the company provides free parts and service for any damaged part.

6. Lifelong follow-up Service: For the equipment out of warranty period, we only charge cost price of the parts

to replace damaged parts and provide free service.

After-sales Service tel:86-519-88179397 86-519-88173217

After-sales Service Fax: 86-519-88173217

After-sales Service Mobile: 15189761688 13057131011

After-sales Service Email:001@zejsj.com

Our advantages

Changzhou Zhuoer Reducer Equipment Co.,Ltd. specializes in production of worm reducers. The company

produces high-quality and high-reliability reducer products and is devoted to becoming the best reducer

equipment manufacturer of China, and providing enterprises of China with the most excellent reducer system

solutions and product service.

The main products of the company are Zhuoer reducers. Its products include BX cycloidal pin gear reducers,

R.S.K.F helical gear reducers, WJ reducers, WP cast iron worm wheel reducers, MB miniature cycloidal

reducers, RV aluminum alloy reducers, MB stepless reducers, SWL screw rod reducers, ZSY hard tooth

surface reducers, SCW arc-contact worm reducers, T helical gear steering gears, small gear motors,

elevators, etc, which are widely applied to numerous industries such as metallurgy, packaging, textiles,

plastic machinery, chemicals and electrical machines.

The company is one of main suppliers of enterprises in surrounding areas, such as Changzhou Reducer

Integral Plant Co., Ltd. and Wuxi Reducer Manufacturing Co., Ltd. Welcome to contact us.

| Payment Terms: | 100% T/T Advance. |

|---|---|

Member Information

| Changzhou Zhuoer Reducer Equipment Co.,Ltd. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 88179397 |

| Contact: | Cammy (sales assistant) |

| Last Online: | 11 Aug, 2015 |