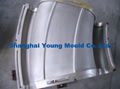

Rotational aluminum tooling mold or roto molding which is a high temperature, low volume, low pressure thermoplastic forming process

Mainly suitable for producing hollow, one-piece parts such as large oil or chemical tanks, kayaks, point of purchase displays, frames, cases, furniture, carts, dispensers, park equipment

The material can be UV-resistant which can ensure the outdoor use of your products

Advantages:

- The cost of plastic rotational mold is low

- The edge of rotational molding products can reach more than 5mm

- Various inserts can be placed to rotational mould

- The shape of rotational molding products can be very complex

- Rotational molding products can be produced fully closed

- Rotational molding products can be filled with foam material, to achieve thermal insulation

- No need to adjust the mold, the thickness of rotational molding products can be adjusted

- Available to deal with various surface patterns and produce products in various colors