| Model: | customized |

|---|---|

| Brand: | Believe Industry |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Hydraulic Pressure Machine & Parts |

| Label: | roll forming machine , roof roll forming , roof sheets machine |

| Price: |

US $20000

/ set

|

| Min. Order: | 1 set |

Product Description

Description:

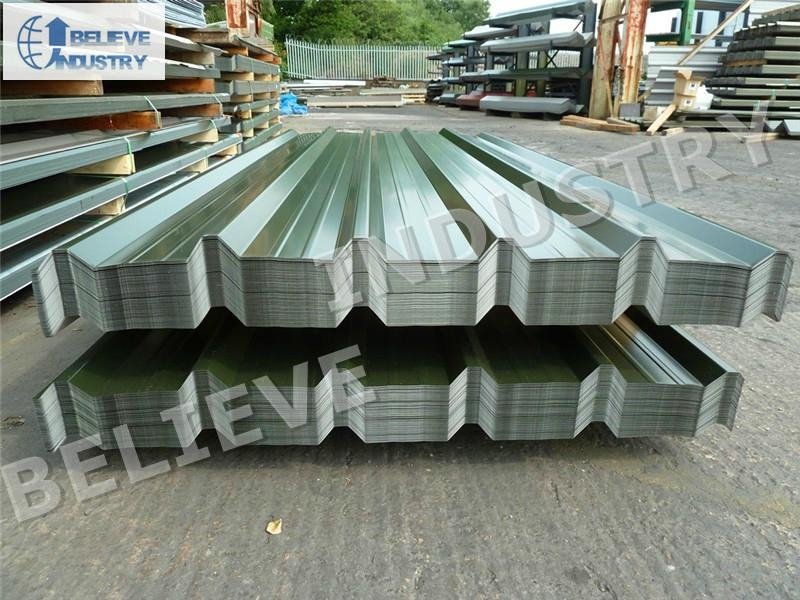

Widespan is a roofing and cladding profile designed to provide an economic alternative to deeper Box Rib profiles without losing the aesthetic appeal of a square fluted profile. The trapezoidal Widespan profile offers greater covering. Widespan roof sheets are available in a wide range of materials displaying various structural properties.

It should be noted that the load span characteristics are only to be used as a broad guideline as purlin spacing is also dependant on other factors such as the prevailing winds in a certain area, snow during winter periods, the presence of dust and other particles in industrial areas, the type of structure that is being erected etc. We therefore recommend that an engineer is consulted to determine the purlin spacing for a specific application. Widespan can be factory cranked, curved and bullnosed to various radii depending on customer's requirements.

Available dimensions:

Widespan sheeting is available in standard lengths up to 15 metres. The permissible length tolerance for the standard length range will be -+5 mm. Sheets outside these parameters are available on request and might be subject to special pricing arrangements. The maximum height which can be transported is 4.3 metres. This factor should be taken into account when bullnoses and curves are designed.

Roof pitch:

When using Widespan, the recommended minimum pitch for roof slopes in excess of 30 m is 10.0º and for slopes less than 30 m is 7.5º. When Widespan roof sheets are end lapped the roof pitch should be taken into account. The minimum end laps for roofs pitches in excess of 15º is 150 mm and for other roofs a minimum of 250 mm is recommended. End laps for side sheeting should be at least 100 mm. It is recommended that end and side laps on low pitched roofs are sealed to ensure watertightness.

Installation procedure:

The required number of Widespan sheets can be calculated as follows: Number of sheets = Length of building + gable end overhangs - 50 mm / 0.762 m (Cover width of sheet). Roof sheets must be laid with one corrugation side lap with the narrow flute uppermost and shall be fixed through the crests of alternate flutes to purlins using 57 mm Top Speed or Tex screws into steel purlins and 90 mm Tex or Top speed screws in the case of timber roofs, all fasteners shall incorporate 19 mm dia bonded washers.

For vertical wall cladding (side cladding) it is recommended that the broad fluted are fixed externally with the main and side lap fasteners in the web of the flutes. Side cladding can be fixed using 25 mm Tex or Top speed screws, all fasteners shall incorporate 19 mm dia bonded washers.

Technical Parameters

Uncoiler: Manual Uncoiler

- Coil Inner Diameter: 508-610mm

- Coil Outer Diameter: max 1500mm

- Loading Weight: 5T

Roll Forming Machine

- Main Structure of the Machine: 36# “H” Beam Steel

- Rolling Stations: 16 stations (subjected to final design)

- Forming Speed: Approx. 10-12m/min.

- Diameter of Shaft: 75mm

- Tolerance of Shaft Dia.: +0-0.03mm

- Material of Shaft: 45# steel with heat treatment HRC50~55

- Material of Roller: 45# steel with quenching treatment and chroming of 0.05mm thickness

- Tolerance of Roller Hole Dia.: +0.03-0mm

- Transmission: Chains-bracket

- Motor Power:5.5KW (subjected to final design)

- Brand Motor: Chinese Guomao

Hydraulic Cutting Device

- Material of Cutting Mold: Cr12 Steel with quenched treatment HRC 60-62

- Cutting Length and Quantity: Clients can set the length and quantity on the PLC touch screen

- Hydraulic Station Power: 3KW (subjected to final design)

- Tolerance of Cutting Length: +/-2mm

Control System

- PLC Control Box: 700mmx1000mmx300mm

- Computer Control System:Panasonic PLC

- Encoder: Omron Brand

- Pressure of Hydraulic Station: ≧16Mpa

- Current: 380V direct current, 50Hz, 3 phase

| Payment Terms: | TT 30% as deposit, 70% before shipment |

|---|---|

Member Information

| Shanghai Believe Industry Co., Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 62653637 |

| Contact: | Yoyo Yu (Sales Representative) |

| Last Online: | 23 Nov, 2017 |

Related Products of this Company

-

Cable Tray Roll Forming Machine

US $120000