| Model: | DK7763C |

|---|---|

| Brand: | sanxing |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | wire edm , wire cut edm , cnc wire cut machine |

| Price: |

US $33333

/ set

|

| Min. Order: | 1 set |

Product Description

DK7763CB High precision CNC wire cutting machine

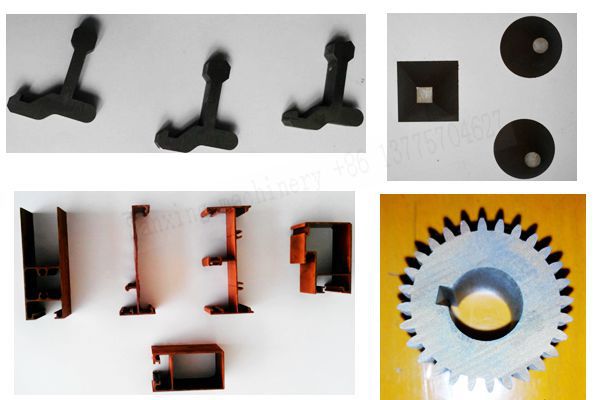

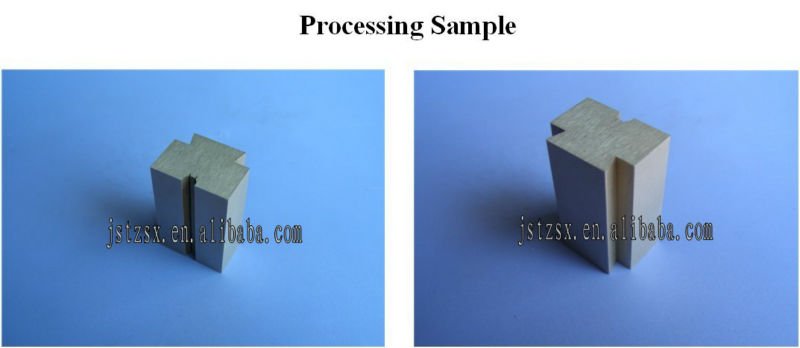

cutting samples

Real cutting samples by High speed CNC wire cutting EDM machine

optional

1.Autocut ,HL ,HF control system optional .

2.Aluminum cutting function available

3.Workpiece thickness adjustable,even 1000mm

4.Cutting speed 5-11.5 adjustable

5.Taper angel :±6degree,±15degree ,±30degree.

6.Taiwan ABBA linear guide

7.AC servo motor .

8.Windows XP /98 ,DOS operation system .

9.Lenovo /HP computer .

10.Environmental cover .

11.DRO , accuracy of 0.005mm.

12.Higher speed control , speed up to 160mm2/min.

13.ulti cut funtion to reach better accuracy and surface roughness.

14.OEM Color

15.OEM brand .

Product Description

Parameters :

|

Type |

DK7732 CB |

DK7740 CB |

DK7750 CB |

|

Worktable size |

650×380 mm |

720×460 mm |

826×556 mm |

|

Table travel |

400×320 mm |

500×400 mm |

630×500 mm |

|

Max.workpiece thickness |

250 mm |

250 mm |

250 mm |

|

Workpiece accuracy |

≤0.006mm |

||

|

Best surface roughness |

≤0.8 μm |

||

|

Max.cutting speed |

180 mm²/min |

||

|

Wire running speed |

5~11.5m/s |

||

|

Taper |

6º/100 mm |

||

|

Power input |

3N~50Hz/380V |

||

|

Overall power |

2.6 KVA |

||

|

Cutting liquid |

Special fluid for multi-cutting |

||

|

Type |

DK7763 CB |

DK7780 CB |

DK77100 CB |

|

Worktable size |

1100×720 mm |

1430×900 mm |

1430×1100 mm |

|

Table travel |

800×630 mm |

1200×800 mm |

1200×1000 mm |

|

Max.workpiece thickness |

500 mm |

500 mm |

500 mm |

|

Workpiece accuracy |

≤0.009 mm |

||

|

Best surface roughness |

≤1.0 μm |

||

|

Max.cutting speed |

160 mm²/min |

||

|

Wire running speed |

5~11.5m/s |

||

|

Taper |

6º/100 mm |

||

|

Power input |

3N~50Hz/380V |

||

|

Overall power |

2.6 KVA |

||

|

Cutting liquid |

Special fluid for multi-cutting |

||

Cutting samples :

Machine pictures :

Features :

1.Clean and Nice ,Operation Security.

Adopt New full closed cover,whose structure is much more simple and nice than the traditional

separated machine .Meanwhile the wire structure and the thread frame become one ,which is

better to make the wire route closed ,so there’s no splashing cutting fluid and flowing cutting

fluid on the machine body,as a result ,the machine can keep clean for long time ,easier to clean.

2.Creative invention ,durable in use.

Bearing pedestal used for installing wire reel ,base and machine body are rigidly connected, the

wire reel doesn’t move right and left ,only does front and back ,the movement of thread frame

right and left makes the wire stretch out and draw back,which makes the weight of the moving

part recuse to 1% of the traditional,lowers the vibration when machine works and the attrition

between Transmission parts ,as a result ,highers the stability of the machine .

3.Section cutting ,guaranteeing the accuracy.

The wire consumption mainly focuses on the large current and big pulse width of the rough

process ,the consumption in preliminary precise process is 1/3 of the rough process ,while ,

in precise process,it is below 0.001mm.During section cutting process ,machine works for a

long time ,but its wire surface in the precise process still can keep the roughness well and the

circle degree.Thus ,this machine can make up the defect that the accuracy and surface

roughness of the workpiece are lowered when the wire of the traditional machine works for

a long time , our machine working effect can compare favourably with the slow speed cnc wire

cutting EDM .

4.Easy operation .

The angle of the operator and the wire reel is from the vertical to the parallel,so ,it’s much more

convenient to thread wire and don’t need to move to the left of the machine to fix the wire .

5.Automatic tightening wire ,improved effect .

The machine is installed Constant tension mechanism.After threading wire ,don’t need to tighten

wire manually as the traditional one, but it still can keep the wire tension consistent during the

whole process .

6.The cheapest and best,economical and practical.

The working cost of the traditional reciprocating wire cutting EDM is only 1/6 of the slow speed

cnc wire cutting EDM .Now adopt our “Cutting Method of the Reciprocating Wire Cutting EDM”

on the traditional machine ,not only protect the advantage of “low price ,low working cost “ but

add the advantages of high accuracy and good surface roughness .

FAQ

1.Why you choose Sanxing machinery ?

We're Quality star , Tech star and Service star .

2. If you're the first time to buy the machine from china , how could you trust on us ?

We have a professional tech team , led directly by our boss , who has more than 40years' experiences in this field .Will offer you quick tech supports .

Our service principle :Customers are our friends

3.How about L/C payment ?

Usually total amount <$2W by T/T ,but special countries by L/C at sight is acceptable .

4.What's the MOQ ?

1SET .

5.Do you need agents ?

Yes , we're looking for good partner all over the word .

Packaging & Shipping

Packed by plywood case , exporting standard

Member Information

| Jiangsu Sanxing Machinery Manufacture Co.,ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 13775704627 |

| Contact: | Wendy (Exporting manager ) |

| Last Online: | 14 Sep, 2015 |

Related Products of this Company

-

Big taper CNC wire EDM machine

US $28888

-

CNC wire EDM machine

US $7500

-

ZNC Sinker EDM Machine

US $7000

-

CNC wire cut edm machine

US $6500

-

CNC Sinker EDM Machine

US $22222

-

CNC molybdeum wire cutting edm machine

US $15500

-

EDM CNC wire cutting machine price

US $8500

-

CNC Drilling EDM machine

US $22222

-

Deep hole EDM drilling machine

US $5000

-

EDM wire cutting machine

US $18000