| Model: | H型 |

|---|---|

| Brand: | Xin north source |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Energy Saving |

| Label: | H economizer , The flue gas heat ex , Low temperature econ |

| Price: |

-

|

| Min. Order: | - |

Product Description

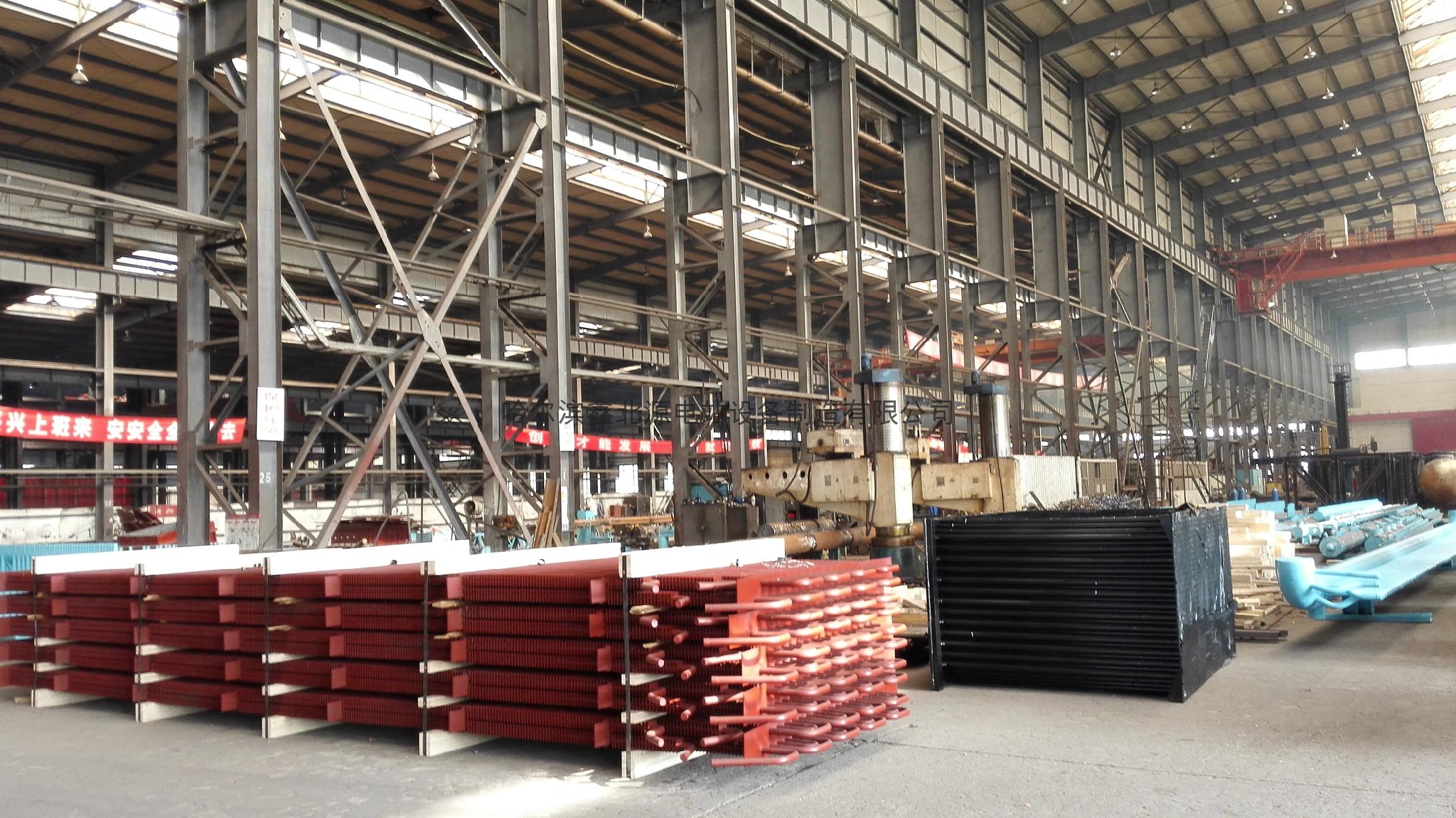

H province coal equipment has the following advantages:

1, change the traditional structure, increase the effective thermal conductivity area

High thermal efficiency, energy saving effect is remarkable. H economizer products through the China special equipment inspection institute, in tests compared with smooth tube economizer, H economizer thermal efficiency is 57.55%, the bare tube economizer thermal efficiency is 37.73%, H economizer than light tube economizer thermal efficiency increased by 19.92%.

2, along the column layout, have excellent wear properties

In H economizer formed by several small flow channel, according to fluid mechanics theory, within the channel, airflow on the edge of the center velocity faster than, flowing particles in the center of channel, thus reduce the erosion of the wall by the particles. Due to H economizer is every two groups of light pipe and h-beam piece combination after welding, enhance its rigidity, compared with the bare tube economizer, under the action of air chamber of a stove or furnace is out of shape not easily, and its structure characteristics make it more particle erosion resistance, longer life expectancy than light tube economizer, therefore, the actual application shows that the general light tube economizer life 6 years, and H economizer can be up to 10 years.

3, H between fins pipe precise suitable column layout, can reduce the dust

Dust formation occurred in tube dorsal surface and windward side. Pipe staggered arrangement easy to flush pipe, less dust on the back. Decorate for paramagnetic column pipe, because the air is not easy to the back flush pipe, in terms of the pipe are deposited along the column arrangement than staggered.

H fins with fins weld on both sides of the tube is not easy to dust, straight and air flow, air flow direction does not change, fins is not easy to dust.

H with 4 ~ 10 gap between fins may guide airflow purging pipe fins dust.

Spiral piece by guide airflow finned helix Angle change direction, finned tube soot formation is serious, for forming loose dust collecting economizer, cannot use. The field operation practice shows that H fin tube is not heavy, and spiral piece of heavy fin is serious.

Longitudinal fins tubes with fins weld deposited in the windward side and the back, due to the flowing stream in the fins, form vortex flow to the pipe to change direction. Parts easy to form sulphuric acid.

H fins because both sides form a straight channel, can obtain the best blowing effect.

4, compact space, reduce the cost

H fin tube multi array arrangement, and through strict calculation of flue gas flow rate and velocity in the flue, determine the best clearance tube group, make the velocity of flue gas and tube wall heat conduction effect best, group tube spacing is compact, greatly reduces smoke of tail shaft height.

Reduce the engineering investment. Because H economizer design of structure is compact, save material, small volume, boiler, after using can reduce furnace overall height, and accordingly reduce the boiler room height, thus form a complete set of project construction cost can be saved.

5, and decrease the drag of the flue gas side

H row economizer tube array after the fins are consequent arrangement, each group of exhaust pipe installed between the fins of tolerance is less than + / - 1 mm, can guarantee the flue gas flow in the fins direction pass, reduce resistance, in this way, and light tube economizer flue gas flow in the form of basic quite, can not change the flow rate of the induced draft fan reduce induced draft fan operating and investment cost.

6, reduce joint, and improve the reliability.

H economizer with fin chip design, expanded the cooling area, using flash resistance welding method, after the welding seam high fusion rate, has a good heat transfer performance and the temperature rise of the economizer pipe water temperature can be obtained quickly and the effect of high temperature range, equal to increase the cooling area, compared to other forms of economizer joint minimum H economizer, such, can not only reduce the machining difficulty and cost, and weld tensile strength is big, also can be caused by welding the possible uncertainties related to damage, improve the reliability of the economizer.

Member Information

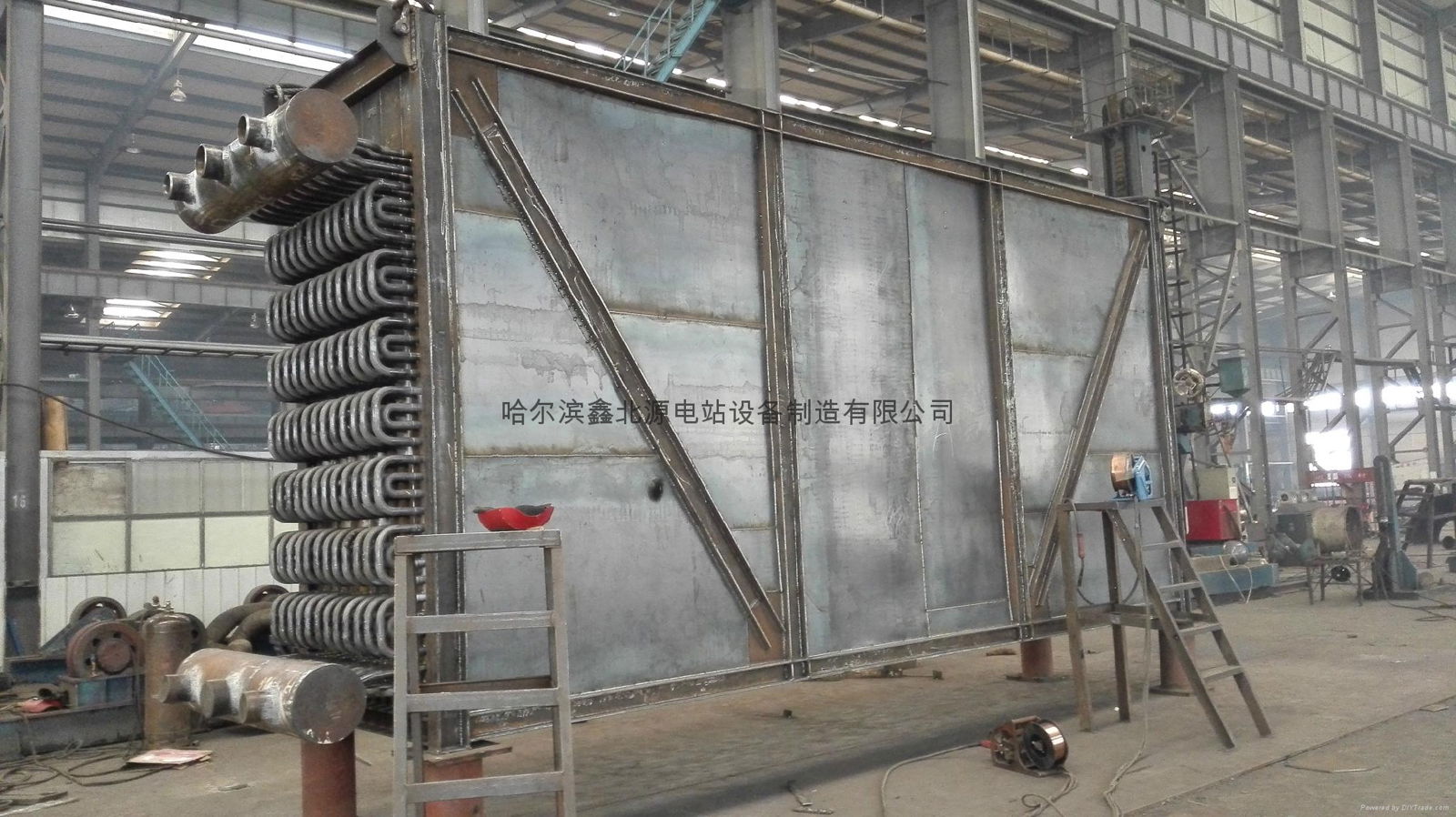

| Harbin xinbeiyuan Power Equipment Manufacturing Co.,Ltd | |

|---|---|

| Country/Region: | Hei Long jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15145131123 |

| Contact: | wangxiaojun (Project Manage) |

| Last Online: | 03 Sep, 2020 |