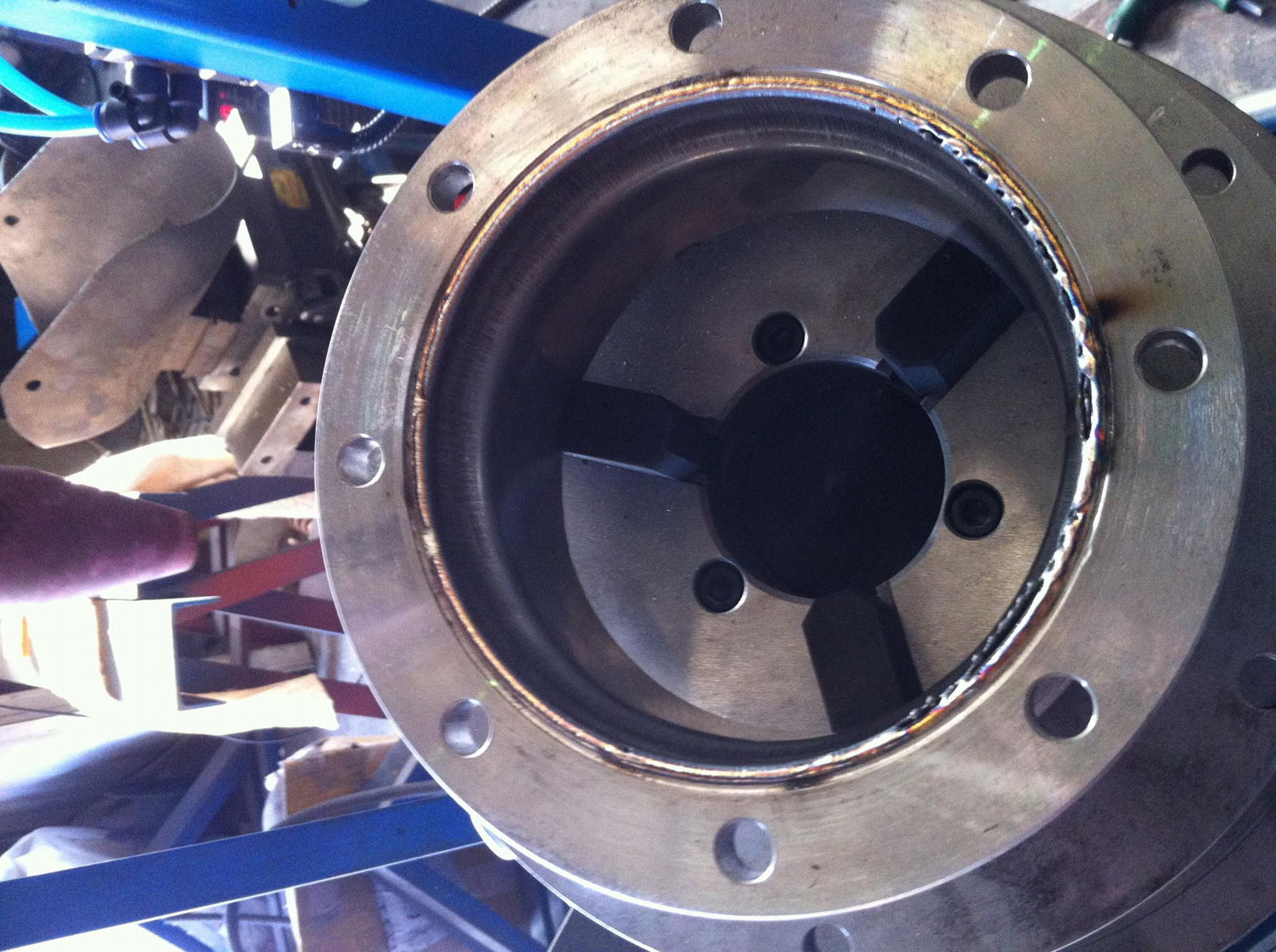

Ring seam welding machine

Automatic welding machine is a kind of universal automatic welding equipment which can complete all kinds of circular and circular welding seam welding. It can be used for high quality welding of carbon steel, low alloy steel, stainless steel, aluminum and its alloys materials and choose welding (filler wire or filler wire), melting pole in gas protection welding, plasma welding and other welding power source to form a girth automatic welding system.

It can be widely used in hydraulic cylinder, car steering frame, transmission shaft, gas storage cylinder, chemical and medical containers, liquefied gas tank, fire fighting equipment, mining and production line roller and the liquid storage tube products welding.

According to the shape of the workpiece is not different, can be divided into the following ring seam welding machine:

Welder a vertical.

Automatic welding machine for B horizontal ring

The welding positioner

3 welding machine (aka welding center)

The automatic welding seam profile ring

Which kind of welding machine is applicable to the welding machine, the main structural features are as follows

1. A vertical ring seam automatic welding machine representation method: HF (L) of its meaning for ring joint (LI), below give a welding ring diameter 600mm model technical parameters are as follows

Control power: single-phase 220V, 50HZ structure: single column tilting

Tilt adjustment mode: stepless, worm gear adjustment

Tilt angle range: 0- 90

Can be welded workpiece diameter (mm): 0~600

Spindle speed: 0~7rmp or 0.5~14rmp

Ring seam welding range: 0~1080 degree

Pneumatic gun stroke: 100

Gun manual fine-tuning: X, y, from Z to 60mm

Maximum current 300A

Vertical ring seam automatic welding machine is a small, cheap, easy and convenient operation, can complete a variety of small circular, annular weld general automatic welding equipment. The biggest characteristic is that it is suitable for the welding of some small parts of the ring, and the workpiece is not too long.

The main controller adopts the motion controller as the core control unit, which is based on the user's request. The whole device has a strong intelligence and flexibility. It is a controller with high quality, high cost performance and reliability. The controller has to manually adjust and control functions for automatic welding; slewing mechanism is driven by a DC servo motor, stepless adjustment of welding speed, welding speed by the control panel digital display; speed control circuit for the independent, weld overlap can be pre digital setting and welding torch high speed reduction; the controller can be according to the requirement of welding process using a variety of control output signal and output interface, with strong anti-interference, high reliability, stable speed regulation, convenient operation, automation degree high, widely used circular weld workpiece welding control