| Model: | DMZ |

|---|---|

| Brand: | Xingnuo |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | concrete pole machin |

| Price: |

US $100000

/ set

|

| Min. Order: | 1 set |

Product Description

Company Information

Zhejiang Xingnuo Co., Ltd is a leading manufacturer producing complete set of prestressed and reinforced Concrete spun pole production equipment and passes ISO9001:2008 quality management system certificate.

Concrete conical spun pole machines fabricated by XINGNUO company have been widely used power transmission, telecommunication, etc. According to standards from different countries, XINGNUO company will design new technical specification and fabricate them according to customers' requirements. Such as changing of diameter, components materials, taper ratio, breaking load, etc. XINGNUO company is very professional factory with most experienced engineers team in China. We have confudence to provided best products for our every customers!

Product Description

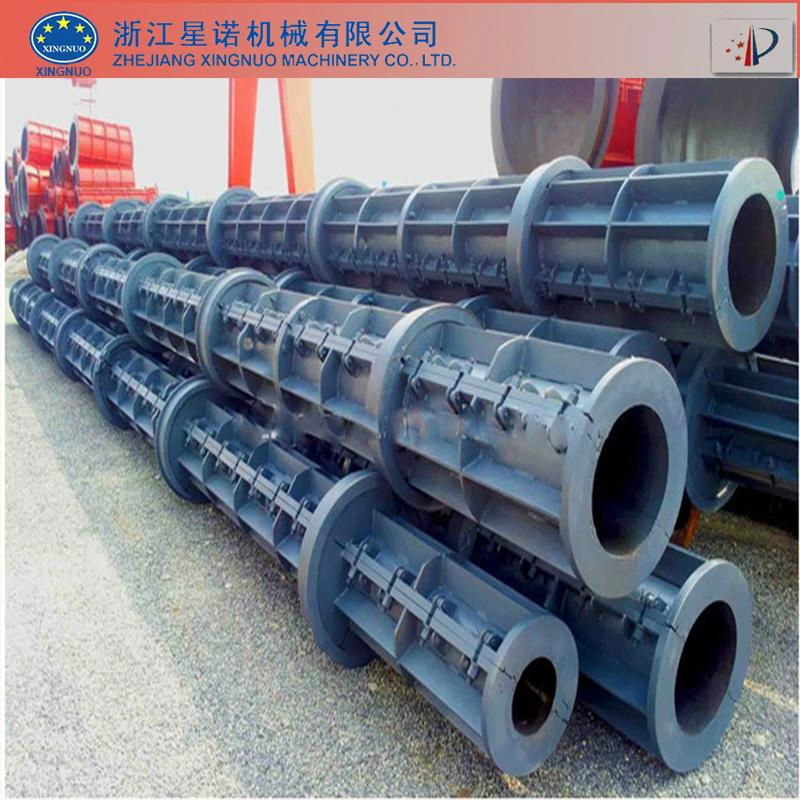

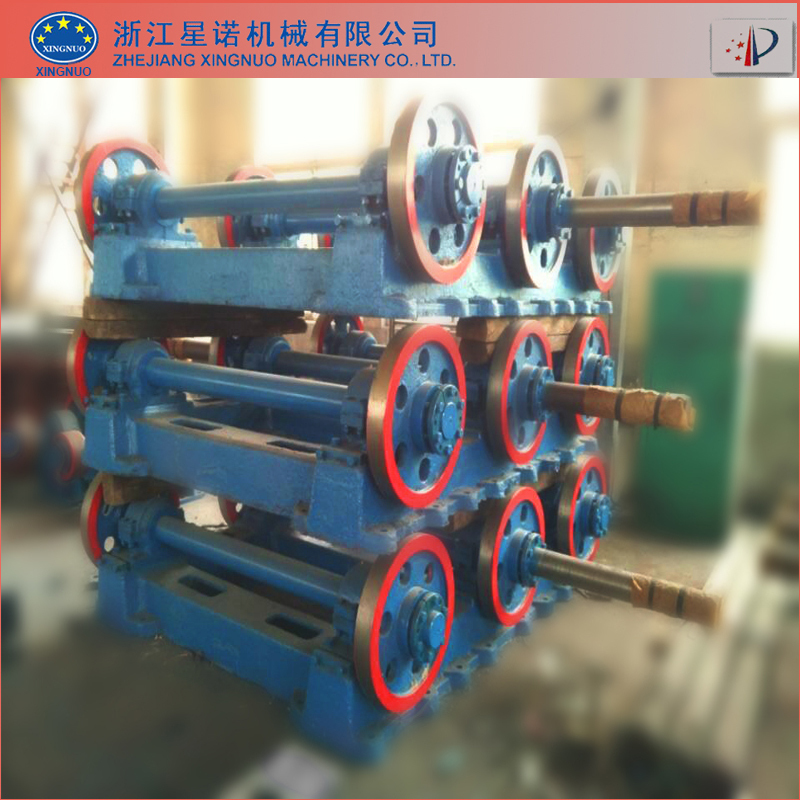

Concrete Steel Spun Pole Mould:

XINGNUO Concrete pole mould is semi-circular double-segment structure, classified cylinder mould and conical mould ; specification: conical mould: diameter Φ100-Φ470mm,length 6-15m,taper1:75; cylinder mould:diameter Φ200-Φ400mm,length over 6-10m;

XINGNUO Spun Pole mould can be applied to both prestressed and reinforced concrete poles producing for power transmission in rural areas or urban areas.

To produce middle voltage concrete poles , Steel mould of 15m will be needed which will be divided into 4 pieces,two pieces for length under 8m,others separated into 3 pieces.

In order to open the mould more conveniently,the steel mould is designed and produced by upper and lower moulds combining together.

To guarantee the roudness of the products when spinning on the centrifugal machine,in case of any leak of concretes and reduce misplacement gaps,groove and tongue joint should be fabricated on the connecting surface of the partial mould.Groove and tongue joint is classified into trapezoid and concave-convex two kinds of shapes.

Mold wall is manufactured by10mm steel plate of Q235 or Q345,longitudinal and transverse bar are made by 10*100mm steel plate,intersection angle of every two longitudinal bar is 37°.

Reinforced plate is rivet welded by 22*100mm steel plate.

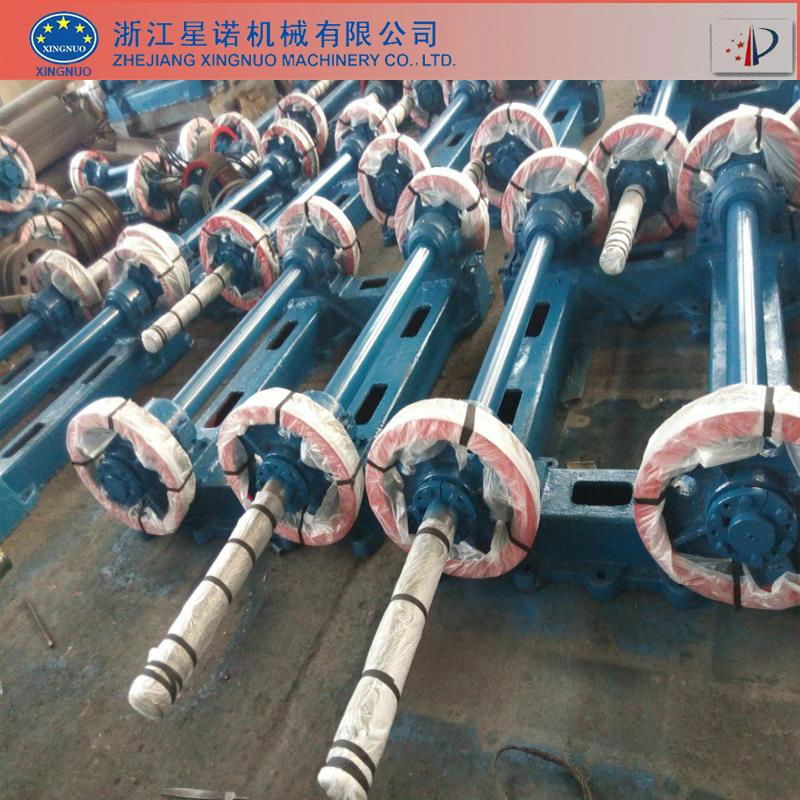

Running wheel is manufactured by ZG35,diameter is 600mm,width 95mm,standard wheel distance is 2m or integral multiple of 2m(there is also 3m non-standard wheel distance).Running wheel installed on the supporting board,connected by bolts.

Conical concrete pole taper is 1:75 or 1:65.

When connecting the segments,assort the flange and spigot,connect every segment with bolts.Molds under the same specification are switchable,and can be combined into all lengths of steel mould according to the request.

Feature

1. Saving a great deal of steel, about 30~70% (employ cold-drawn steel wire can save 30%~60%; employ high tensile steel wire can save 40%~69%).

2. Crack resistance can increase by about 3~5 times.

3. Rigidity increases 1~3 times.

4. Reducing the production cost (using cold drawn steel wire can reduce 25%~40%; using high stress steel wire can reduce 12%~21%).

5. Good durability, can delay the existence and expansion of cracks.

Related products

Centrifugal machine

FAQ

1. Specifications of Concrete Poles . Such as Length , Top Diameter, Bottom Diameter , Taper Ratio, Ultimate Load, Breaking Load etc.

2. Type of concrete Pole: Pre-stressed or Reinforced .

3. Productivity

4. Old Factory and machines updating or New Concrete Pole Plant Building ?

Packaging & Shipping

Different Machines with Different Package, Plastic and Thick Paper, Wooden Box etc.

Our Services

1.Complete production line supporting machines and all necessary accessories with high performance and good quality;

2. Free Service of plant structure design and layout plan drawings and other necessary construction drawings and guidance of construction work,office, warehouse etc and related drawings according to customers’ requirements.

3.Installation and commissioning of all production machines as well as the workers training.

We will make every effort to provide different consideration solutions for prestressed concrete pole plant according to different requirements of our clients !

Warmly Welcome To Visit XINGNUO Factory !

Any Questions, just contact me !

Member Information

| Zhejiang Xingnuo Machinery Co., Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15963613726 |

| Contact: | Carol Han (Seller) |

| Last Online: | 15 Oct, 2015 |

Related Products of this Company

-

Spun Prestressed Concrete Pole Steel

US $100000

-

China high quality Concrete electricity

US $100000

-

Prestressed Concrete Pole Production

US $100000

-

Prestressed Concrete Spun Pole

US $100000

-

Prestressed Concrete Pole Centrifugal

US $100000

-

No Image

Prestressed Concrete Pole Production

US $100000

-

Electric prestressed concrete pole

US $100000

-

Prestressed Concrete Pole Machine

US $100000

-

Concrete elelctricity pole manufacture

US $100000