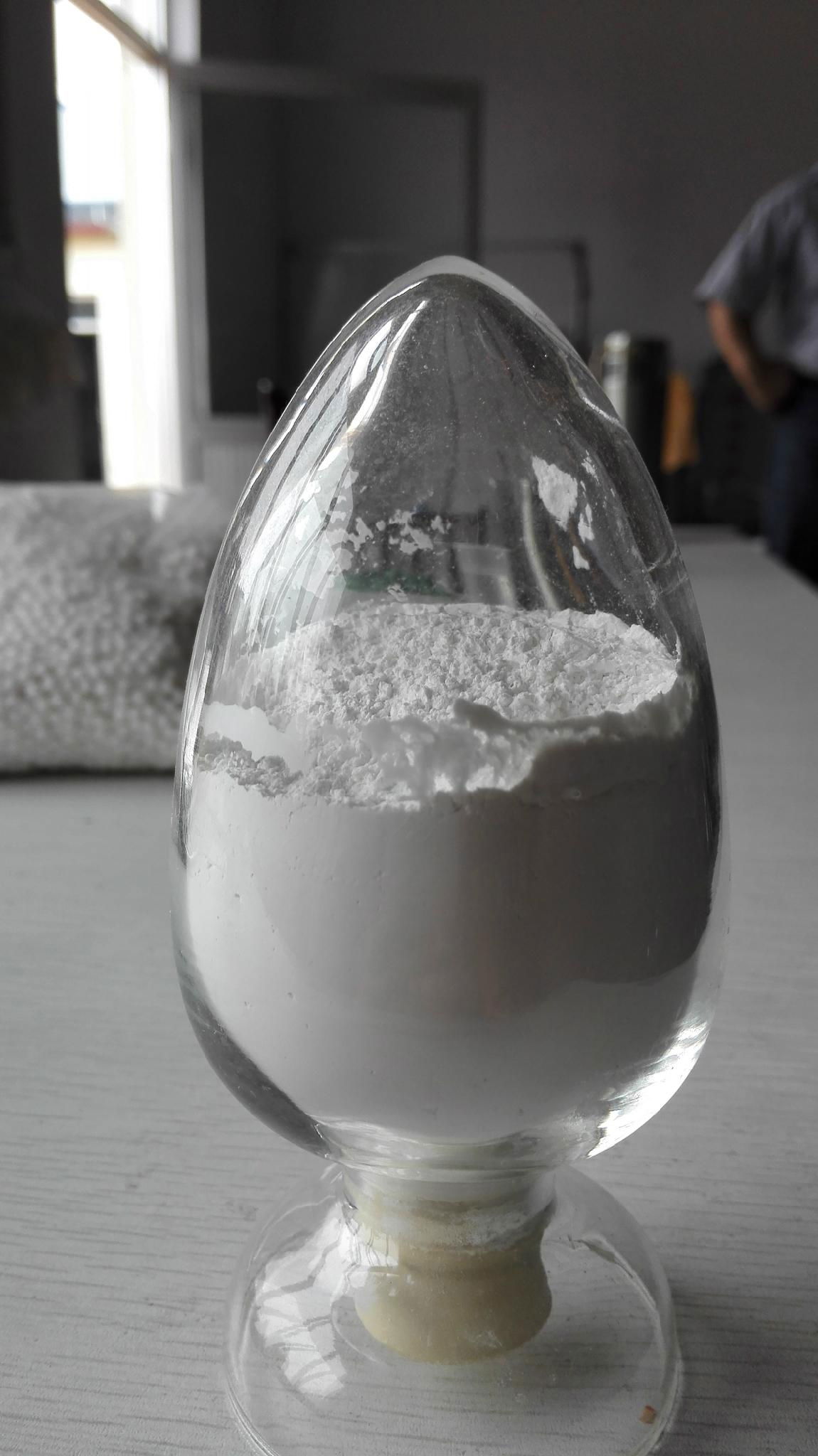

1. White Aluminum Oxide is fused from high quality bayer aluminum in high temperature. Its hardness is higher but toughness lower compared with Brown Aluminum Oxide. It is chsaracterized by high purity, excellent self-sharpening, efficient grinding efficiency, and low frictional heat. It can withstand acid and alkali erosion, with high temperature resistance and good thermo stability

2.Product advantages:

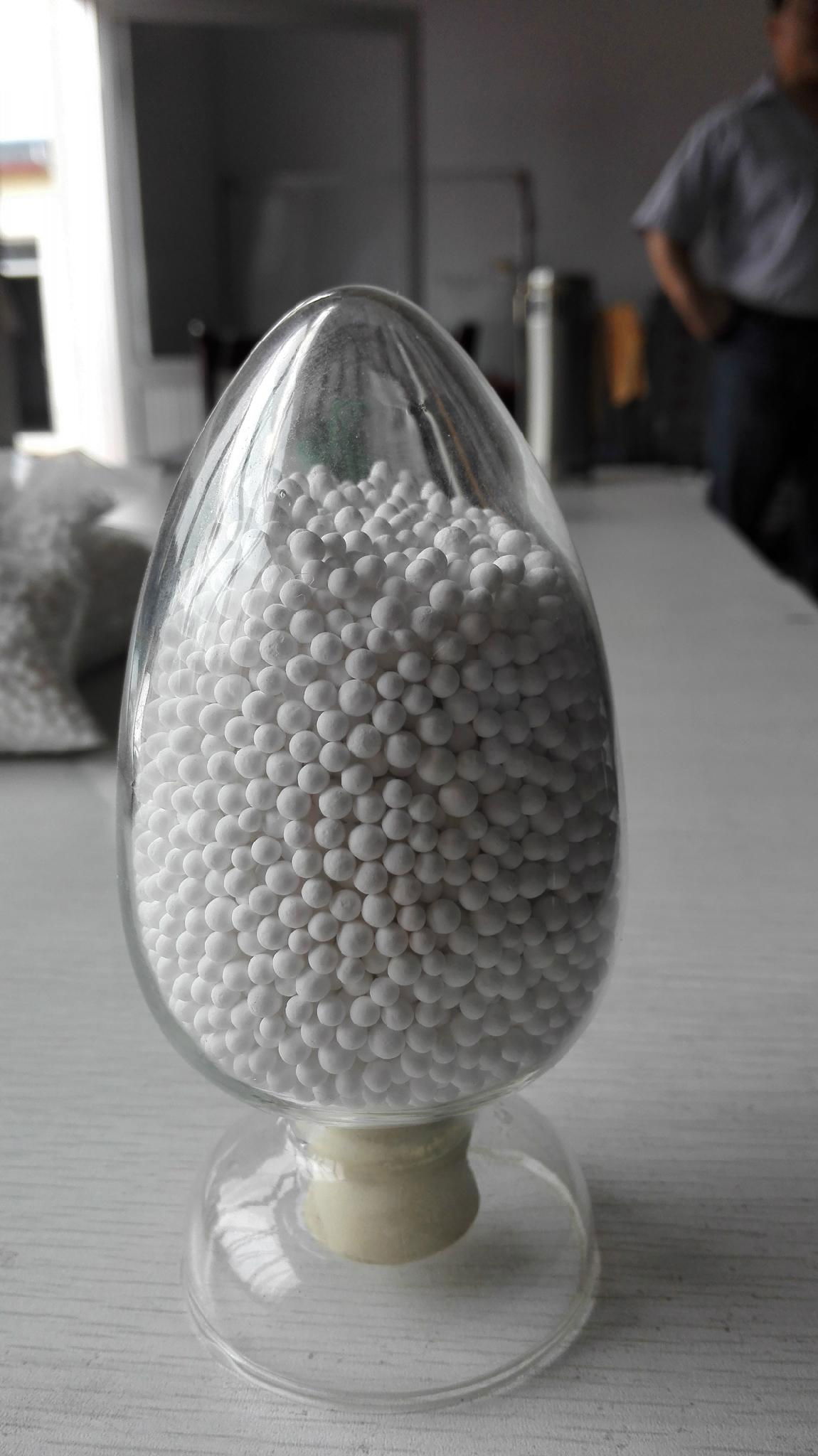

1. Uniform ball size.It can be in as far as possible to reduce the pressure to reduce cases of high pressure gasfor drying. Its flat ball size prevents the pneumatic loading appeared in the process of adsorption separation,so as to minimize channeling, more effective use of dry absorption tower.

2. High compression strength. Its high compression strength which can guarantee the gas quickly through the absorption tower. At the same time, high compression strength makes it more effectively for gas drying of absorption tower. It can effectively prevent the ammonia gas sensor. In addition, the high compression strength of our activated alumina can make it dry acidic substances such as carbon dioxide gas and liquid, and provide long-term service life.

3. Low wear. low wear performance of our activated alumina can ensure the reduction of dust production in theprocess of gas/liquid carrying, lower the gas pressure in its working process, minimize and prevent the reverseflow and gas filter blockage. It is usually used with some of the dust gas.

4. Large amount of adsorption.High specific surface area and Specially made needle distribution of our activated alumina make it absorb a lot of water. By absorption tower design and effective regeneration, our activated alumina can reduce wastewater emissions (e.g, dew point).It also has a high stability of the crystal to ensure itslong service life.

3. Application:

1)Drying. Almost all of the gas and fluid can use activated alumina for drying.Moisture removal is necessary in the

process of efficient production and fluid transportation.5/6 mm activated alumina is usually used for water vapor

absorption which requests gas pressure drop in the smallest.4/5 mm activated alumina was used in fluid drying and other fluid absorption applications.Our activated alumina is also applicable to industrial compressorgas drying.It can keep good work performance under low dew point,our activated alumina is suitable forvarioussize of dryer machine.Can also be appliedfor gas drying under the environment of the regeneration environment (350 ~ 600°F) and pressure (PSA).

2).Removal of acid impurities. Remove the acid created in the using process of oil, lubricating oil and coolant. Activated alumina can remove acid material in the process of its use. In the process of chlorination and fluorination hydrocarbons, remove excess of halide and water is necessary to produce no corrosive products.