| Model: | CDP-001 |

|---|---|

| Brand: | C&D |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Filters |

| Label: | Wire-wrapped screen , Wire-wrapped screen , Wire-wrapped screen |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Product introduction

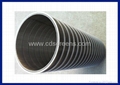

Stainless steel wire wrapped screen is also known as "all-welded wire wrapped screen". Slot tubes are composed of a surface profile which is spirally wrapped around the axial support profiles and attached to each other by resistance welding. These filter elements have the unique advantages of accuracy, narrow slot openings and perfect roundness. Slot tubes can be provided with the necessary end pieces for attachments and/or reinforcements.

Advantages

1. No blocking: the cross profile of the screen wire is trapezoidal (also triangle), the slot is formed by the closed angle of two neighbouring wires. While the solid passing the screen, it is point contact between solid and two side of slot. So in theory, the solid particles on the screen either trapped in the screen, or through the slot , it is impossible to have a third blocked state. This is very important to reduce the running resistance of the device, to maintain good water distribution characteristics, enhanced backwash effect of the resin.

2.High intensity: Since this element uses a stainless steel wire around the welded structure, it has a high strength. This screen can be cut at the wheel cutting machine and processing lathe without distortion.

3. Flow volume: This screen has relatively smaller resistance, so compared with the dimensions of similar plastic filter, it is greatly increasing its flow area. And in the same resistance, flow volume is significantly increased. In other words, in the case of the same output, the number of water treatment cartridge can be reduced accordingly.

4. Good temperature adaptability: compared with the ordinary plastic filter, the operating temperature range of the stainless steel wire wrapped screen is much wider.

5. Adjustable slot: as for different users, having different filtration equipment and filter medium, they have different requirement of the screen slot size. And our screen is constantly welded on special equipment, so screen slot size is adjustable. By this way, the screen slot can meet customers’ requirement without increasing cost, however, the plastic filter cartridge have to make new mold for different slot size. It is difficult to meet special requirements of users.

6. Corrosion resistance: As mentioned above, there are three material in the domestic stainless steel sieve, these three materials can fully meet the requirements of the current water treatment technology. For neutral water, acidic water, alkaline water, regenerant caustic soda, hydrochloric acid, sulfuric acid, salt, etc., as long as these materials is selected reasonably, can use various types of filtration devices economically and safely.

Application

1. Resin: for ion exchanger water input device, water collection device and resin trap, prevent broken resin into the next production systems, but also can capture large amounts of resin leakage in the exchanger accident. The resin trap made before is often overwhelmed for instablity because a large number of resin leakage leads the inlet and outlet pressure increasing. Now, all the resin trap equip with porous liner and stainless steel screen pipe, greatly improving the reliability of equipment operation.

2. Beer and other alcoholic filtering: the outside of candle screen pipe in the candle diatomite filter is filled with diatomaceous earth, after use, can save 92% energy, reduce 90% wine loss, save two-thirds equipment cost and reduce 3/4 production workers. The flavor of filtered wine and drinks is unchanged, it is non-toxic, no suspension, no sediment, clear and transparent, high filtration, small covered area, lightweight and flexible, easy to move.

3. Steel: for raw materials, sintering pellet plant water treatment filtration, blast furnace, rolling mill, continuous casting machine cooling water filtration, high pressure water phosphorus impurities filtration system

4. Automotive:widely used in coating production line and water treatment system of car,tractor, motorcycle and engine manufacturing.

5. Power plant: preprocessing for precision of the power plant and boiler high pure water preparation; the generator cooling water and seal water filtration

6. Water system: When the water flow is particularly large,used as a auxiliary filter.

7. Petrochemical: can be single or multiple machines in parallel as auxiliary filter in circulating water, replace the material filtration, reduce the filter material load, can avoid a lot of flushing water consumption, cost savings.

8. Agricultural landscape and paper mills: If there is the nozzle in the system, should reduce the equipment blockage and wear due to the impurities, so need to choose high precision, high automatic filtering products to prevent the cooling water system clogging.

9. Mine: filtering underground water to ensure the system is working properly..

10. Water supply and wastewater treatment: used for pretreatment system, improving the system efficiency

11. Food and beverage: for solid and liquid separation and prefilter, to achieve the food and beverage production health and safety standards.Widely used in drinking water treatment, construction circulating water treatment, industrial circulating water treatment, wastewater treatment, mining water treatment, golf course water treatment, also used in construction, steel, petroleum, chemical, electronics, power generation, textile, papermaking, food, sugar, pharmaceutical, plastics, automotive industry and other fields.

Technical parameters

Slot(mm) : 0.02, 0.025, 0.03, 0.04, 0.05, 0.06, 0.08, 0.10, 0.15, 0.2, 0.25, 0.30-35, also can be produced according to customer's request

Material: low carbon steel, mild steel galvanized, plastic spraying, stainless steel (304316 L, hartz alloy, etc.)

Length: 50 mm - 6000 mm

Outer diameter: 25 mm - 600 mm

Connection: groove connection or threaded connection, pipe or thread head directly

Wire specifications: 1 * 0.75 * 1.5 mm, 2.3 2 mm, 2 * 3 mm * 3 mm, 3 * 5 mm

Support rod: DN25mm/12pieces、DN33mm/8 pcs、DN37mm/8 pcs、DN40mm/10 pcs、DN60mm/12 pcs etc.

Member Information

| CDSCREENS CO.,LTD | |

|---|---|

| Country/Region: | Si chuan - China |

| Business Nature: | Manufacturer |

| Phone: | 15928650174 |

| Contact: | Jocelyn (Sales Manager) |

| Last Online: | 17 Sep, 2017 |

Related Products of this Company