| Model: | - |

|---|---|

| Brand: | LFJS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Other Metallic |

| Label: | - |

| Price: |

-

|

| Min. Order: | 1 kg |

Product Description

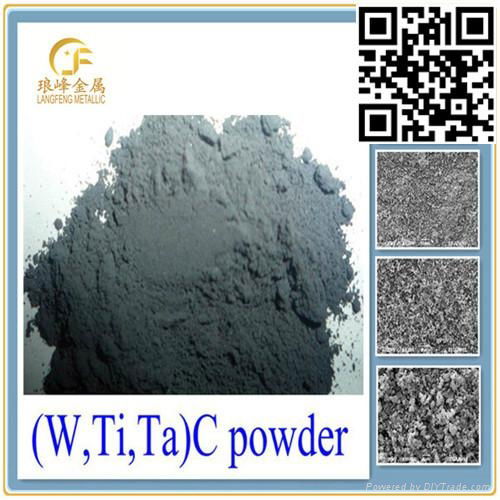

Compound carbide powder Thermal spray powder, (W,Ti)C powder, Tungsten Titanium carbide ceramic grade powder PCT cutter best material supplier in china, 3WCTiC, (W,Ti)C powder, Tungsten Titanium carbide ceramic grade powder

Product introduction:

Compound carbide powder is a kind of raw material extensively applied in hard alloys industry and other new materials industries, and generally it is made by solutionizing two or multiple kinds of carbide and other compound (such as nitride). Adopting unique carbonizing and solutionizing processes, our company produces compound carbide products with advantages such as stable composition, even distribution, high solid solubility, low impurity level and controllable granularity, and the tailor-made products are also available in the company to meet the customers’ specific requirements.

Product application:

As the addictives in hard alloys and cermet, it can improve the performance of hard alloys. Also it can apply in hot spraying, plasma spray coating, hard thin film, and electric conduction.

Carbide compounds tend to be extremely hard, refractory and resistant to wear, corrosion and heat, making them excellent candidates for coatings for drills and other tools. They often have other valuable properties in combination with toughness, such as electrical conductivity, low thermal expansion and abrasiveness.

Product technical specification:

|

GRADE |

CHEMICAL COMPOSITION (%) |

|||||||||||||||

|

W |

Ti |

Ta |

Nb |

Cr |

Total carbon |

Free carbon |

IMPURITY(%max) |

|||||||||

|

Fe |

Si |

Al |

O |

N |

Na |

K |

Ca |

S |

||||||||

|

(Ta,Nb)C 91 |

|

|

84.4±0.5 |

8.8±0.5 |

|

6.7±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.15 |

0.05 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(Ta,Nb)C 82 |

|

|

74.2±0.5 |

18.5±0.5 |

|

7.2±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.15 |

0.05 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(Ta,Nb)C 31 |

|

|

71.5±0.5 |

21.0±0.5 |

|

7.3±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.15 |

0.05 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(Ta,Nb)C 73 |

|

|

65.6±0.5 |

26.6±0.5 |

|

7.6±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.15 |

0.05 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(Ta,Nb)C 64 |

|

|

56.6±0.5 |

35.1±0.5 |

|

8.1±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.15 |

0.05 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(Ti,Ta)C |

|

35.0±0.5 |

53.0±0.5 |

|

|

12.0±0.2 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ta)C55 |

47.0±0.5 |

|

46.8±0.5 |

|

|

6.15±0.2 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ta)C 82 |

75.1±0.5 |

|

18.8±0.5 |

|

|

6.1±0.1 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C55-1 |

47.0±0.5 |

39.9±0.5 |

|

|

|

11.7±0.2 |

≤0.1 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C55-2 |

47.0±0.5 |

39.9±0.5 |

|

|

|

12.6±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C55-3 |

47.0±0.5 |

39.9±0.5 |

|

|

|

12.9±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C64 |

56.1±0.5 |

32.1±0.5 |

|

|

|

11.3±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C73-1 |

66.7±0.5 |

23.1±0.5 |

|

|

|

9.4±0.2 |

≤0.1 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C73-2 |

65.5±0.5 |

24.2±0.5 |

|

|

|

10.0±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti)C73-3 |

65.4±0.5 |

24.3±0.5 |

|

|

|

9.7±0.3 |

≤0.1 |

0.06 |

0.01 |

0.01 |

0.3 |

0.15 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-1 |

63.1±0.5 |

10.7±0.5 |

18.0±0.5 |

|

|

7.7±0.3 |

≤0.3 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-2 |

48.8±0.5 |

30.4±0.5 |

9.4±0.5 |

|

|

11.1±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-3 |

47.0±0.5 |

24.0±0.5 |

18.8±0.5 |

|

|

10.0±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-4 |

42.3±0.5 |

17.6±0.5 |

31.0±0.5 |

|

|

9.0±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-5 |

35.7±0.5 |

30.4±0.5 |

22.5±0.5 |

|

|

11.2±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-6 |

36.1±0.5 |

29.7±0.5 |

23.0±0.5 |

|

|

11.1±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-7 |

37.6±0.5 |

28.8±0.5 |

22.3±0.5 |

|

|

10.7±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-8 |

63.1±0.5 |

22.2±0.5 |

4.7±0.5 |

|

|

9.6±0.3 |

≤0.15 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta)C-9 |

31.3±0.5 |

26.5±0.5 |

31.2±0.5 |

|

|

10.7±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Cr)C-1 |

35.0±0.5 |

19.6±0.5 |

35.5±0.5 |

|

0.18±0.04 |

9.6±0.2 |

≤0.25 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Cr)C-2 |

40.0±0.5 |

22.6±0.5 |

27.0±0.5 |

|

0.21±0.05 |

10.2±0.2 |

≤0.25 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Cr)C-3 |

44.0±0.5 |

25.1±0.5 |

20.0±0.5 |

|

0.19±0.05 |

10.6±0.2 |

≤0.25 |

0.06 |

0.01 |

0.01 |

0.3 |

0.2 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Nb)C-1 |

55.3±0.5 |

19.2±0.5 |

9.3±0.5 |

6.2±0.5 |

|

9.7±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Nb)C-2 |

35.2±0.5 |

20.0±0.5 |

23.4±0.5 |

11.1±0.5 |

|

9.8±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Nb)C-3 |

21.6±0.5 |

20.1±0.5 |

39.2±0.5 |

8.8±0.5 |

|

10.0±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

(W,Ti,Ta,Nb)C-4 |

37.5±0.5 |

32.0±0.5 |

11.2±0.5 |

7.1±0.5 |

|

11.7±0.3 |

≤0.2 |

0.06 |

0.01 |

0.01 |

0.3 |

0.1 |

0.005 |

0.005 |

0.01 |

0.01 |

|

Particle size:0.5-500micron, can be requested. Will you want a try? I will always do my best to support you! How to cocntact with Vera? skype:shunjiangu; email:vera at cslfjs.cn; vera at langfengmetallic.com mobile:86-15974242234 (what'sapp) wechat:veragmail; |

||||||||||||||||

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Changsha Langfeng Metallic Material Co.,LTD | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15974242234 |

| Contact: | vera (manager) |

| Last Online: | 28 Aug, 2020 |