| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Construction & Decoration / Timber & Plywood |

| Label: | film faced plywood , plywood , construction materia |

| Price: |

-

|

| Min. Order: | 1000 pc |

Product Description

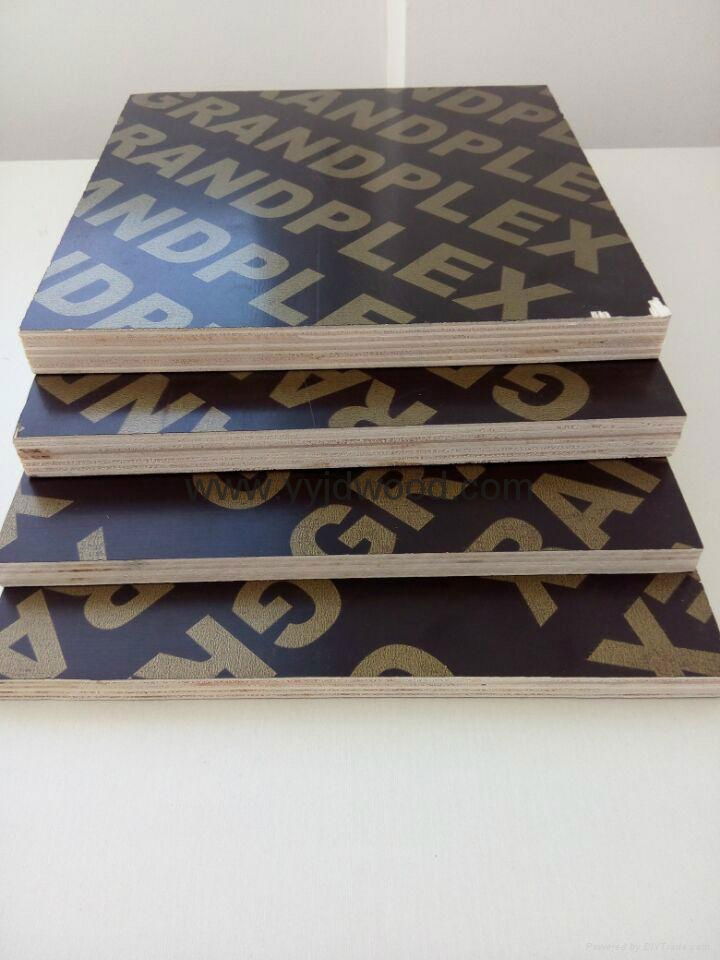

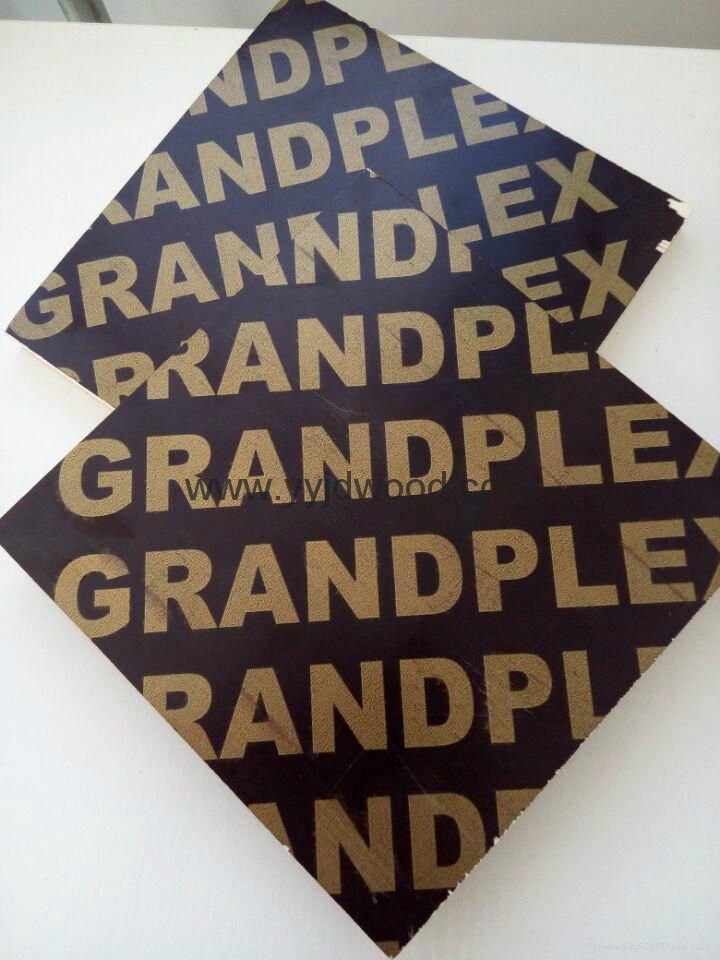

| Product Name | Film Faced Plywood |

| Brand Name | YYJD |

| Specification | 1220*2440*8-21mm 915*1830*11-15mm |

| Film Colour | Red, Brown, Black or with logo on customers request |

| Formaldehyde Emission Standards | E1 |

| Moisture Content | 8-14% |

| Grade | First-Class |

| Glue | WBP or MR |

| Main Material | Poplar, combine, finger joint board |

| Usage | Can be widely used for building concrete, etc |

| Package | Standard export packing |

| Press | one times press/two time press grade |

| MOQ | 1000sheets |

| Port | Lianyungang,Qingdao |

| Price Terms | FOB, CIF |

| Payment Terms | T/T |

| Delivery Detail | about 15-20 days after your deposit or L/C at sight |

| Company website | www.yyjdwood.com |

Film faced plywood is lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface it can be used in open environment in construction and building e.g. warehouses, railway wagons, floors and sidewalls of trucks etc. Coating the film faced plywood with high-quality import films ensures hardness and damage resistance. The surface of the film faced plywood is hygienic and resistant to strong detergents, which is important for farming constructions and storage of food products. It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites.

1. Film is phenolic resin adhesive membrane to make the smooth, low scratched surface and protect the plywood usage. 2.Plywood core is using either Softwood or Hardwood.

3. Plywood includes many layers of veneers that be hot pressed for 2 -3 times with water boiled proof (WBP) glue helping to increase elasticity, hardness of plywood and working capability in wet outdoor condition.

Applications

film faced plywood is used as a formwork in industrial, commercial and civil works. It has many advantages compared to traditional product such as:

1. Absolutely flat concrete surface, no mortar required after casting.

2. Light density, portable, easy for installation. Labor cost saving and project schedule shortening.

3. Waterproof, re-use for many times, high economic efficiency.

4. High compressive strength, response calculated secure in construction.

5. Easy to saw and link each other, favorable for usage.

| Payment Terms: | TT |

|---|---|

Member Information

| Lankao Yiyanjiuding Wood Compay Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18265061856 |

| Contact: | linna li (Sales manager) |

| Last Online: | 29 Mar, 2016 |