| Model: | K-A81 |

|---|---|

| Brand: | JUT |

| Origin: | Made In China |

| Category: | Chemicals / Resin |

| Label: | aldehyde resin , A-81 , Aldehyde ketone resi |

| Price: |

¥26

/ KG

|

| Min. Order: | 100 KG |

Product Description

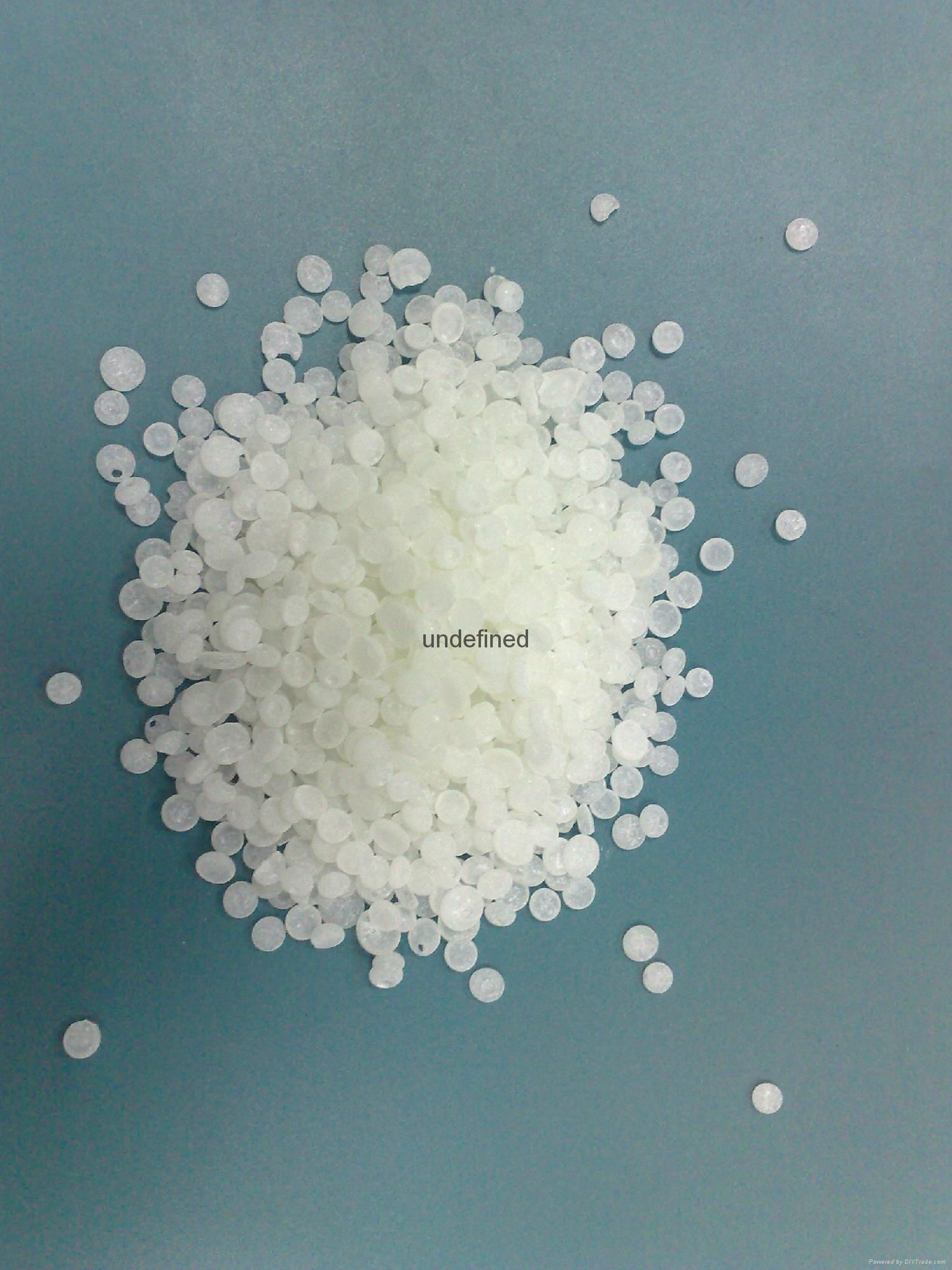

(environmental protection) aldehyde resin K-A81

Overview: this series of products is colorless to slightly yellow resistant to yellowing of fatty aldehyde resin, the appearance of a material. Suitable for solvent based coatings, solvent based inks, solvent based coatings, waterborne coatings, powder coatings, a variety of resin modification and other areas. Its performance to improve the film's resistance to yellowing, shorten the drying time, improve solid content, reducing VOC emissions, more than the price of similar products abroad 30%, especially universal colorants cost can be reduced by more than 50%, of which low solvent to similar foreign products is not its Bimei, product performance has reached and exceeded similar foreign products.

Varieties and specifications:

Shape of a material

Softening range (DIN53180) 80-95

Iodine colorimetric DIN (6162) 3 (highest)

The acid value of mgKOH/g (din53402) 3 (highest)

Hydroxyl value mgKOH/g (IS04629) 40

Glass temperature (DIN53765) 40

Viscosity 25-30 (DIN53015) mpa.s

Characteristic of:

Pigment paste (Universal colorants):

K-A81 has almost universal solubility and solubility, and has excellent pigment wetting properties. Because of this reason that K-A81 is very suitable as carrier resin color paste. With a proper dispersant with use can make the paste with very high tinting strength and reduce the loss in the storage process, reduce inventory and processing of raw materials and color varieties. Improve the market paint pigment changes in the strain capacity, in the shortest time to paint finished products into the market, compared with similar foreign products costs can be reduced by more than 30%. (carrying amount of general K-A81 resin paste can be made into content of 30%-60% liquid according to different requirements).

Content in coatings:

In some coatings, the content of K-A81 formaldehyde resin is too high to affect the adhesion or flexibility or weathering of the coating. General content of 5%-15%, the maximum shall not exceed 20%, if there are special requirements, you can adjust the. Can also be used directly as a paint, ink additive use 5%.

Should use:

We used in the manufacture of auto repair paint, can improve the gloss, increase the hardness, shorten the drying time, adding amount of 2%-5%.

We used in the manufacture of alkyd resin can reduce the viscosity of alkyd resin, increase the hardness, gloss, improve drying performance. In the final phase of the synthesis of K-A81 formaldehyde resin 5%-10% (according to the solid content of alkyd resin).

As the resin modified amino alkyd paint, can improve the hardness, fullness. Can be replaced by no more than 20% alkyd resin according to the quality requirements.

] as nitro paint of modified resin, improve the anti ultraviolet performance, reduce yellowing, improve solid content, to improve gloss, improve the coating of benzene solvent tolerance. Usage: general use as 20%-30% nitrocellulose.

] as alkyd / chlorinated resin paint change resin, enhance chloride resin (especially chlorine ether and chlorinated rubber) and alkyd resin compatibility and improve the coating gloss, improve the coating of solid content. Usage: can replace the alkyd / chlorinated resin coatings in the alkyd part, the amount does not exceed 10% of the total resin content.

] formulated hot-melt road marking paint (compared to and petroleum resin as base material of hot-melt road paint) in the substrate adhesion better, in the white varieties, the amount of titanium dioxide can less, better weather resistance. Usage: 1 can use K-A81 as base material individually; 2 can be used with petroleum resin and.

We used in powder coating, improve leveling, enhanced adhesion to substrate. Usage: in epoxy powder coatings, K-A81 substituted 5%-15% with reactive resin.

Overview: this series of products is colorless to slightly yellow resistant to yellowing of fatty aldehyde resin, the appearance of a material. Suitable for solvent based coatings, solvent based inks, solvent based coatings, waterborne coatings, powder coatings, a variety of resin modification and other areas. Its performance to improve the film's resistance to yellowing, shorten the drying time, improve solid content, reducing VOC emissions, more than the price of similar products abroad 30%, especially universal colorants cost can be reduced by more than 50%, of which low solvent to similar foreign products is not its Bimei, product performance has reached and exceeded similar foreign products.

Varieties and specifications:

Shape of a material

Softening range (DIN53180) 80-95

Iodine colorimetric DIN (6162) 3 (highest)

The acid value of mgKOH/g (din53402) 3 (highest)

Hydroxyl value mgKOH/g (IS04629) 40

Glass temperature (DIN53765) 40

Viscosity 25-30 (DIN53015) mpa.s

Characteristic of:

Pigment paste (Universal colorants):

K-A81 has almost universal solubility and solubility, and has excellent pigment wetting properties. Because of this reason that K-A81 is very suitable as carrier resin color paste. With a proper dispersant with use can make the paste with very high tinting strength and reduce the loss in the storage process, reduce inventory and processing of raw materials and color varieties. Improve the market paint pigment changes in the strain capacity, in the shortest time to paint finished products into the market, compared with similar foreign products costs can be reduced by more than 30%. (carrying amount of general K-A81 resin paste can be made into content of 30%-60% liquid according to different requirements).

Content in coatings:

In some coatings, the content of K-A81 formaldehyde resin is too high to affect the adhesion or flexibility or weathering of the coating. General content of 5%-15%, the maximum shall not exceed 20%, if there are special requirements, you can adjust the. Can also be used directly as a paint, ink additive use 5%.

Should use:

We used in the manufacture of auto repair paint, can improve the gloss, increase the hardness, shorten the drying time, adding amount of 2%-5%.

We used in the manufacture of alkyd resin can reduce the viscosity of alkyd resin, increase the hardness, gloss, improve drying performance. In the final phase of the synthesis of K-A81 formaldehyde resin 5%-10% (according to the solid content of alkyd resin).

As the resin modified amino alkyd paint, can improve the hardness, fullness. Can be replaced by no more than 20% alkyd resin according to the quality requirements.

] as nitro paint of modified resin, improve the anti ultraviolet performance, reduce yellowing, improve solid content, to improve gloss, improve the coating of benzene solvent tolerance. Usage: general use as 20%-30% nitrocellulose.

] as alkyd / chlorinated resin paint change resin, enhance chloride resin (especially chlorine ether and chlorinated rubber) and alkyd resin compatibility and improve the coating gloss, improve the coating of solid content. Usage: can replace the alkyd / chlorinated resin coatings in the alkyd part, the amount does not exceed 10% of the total resin content.

] formulated hot-melt road marking paint (compared to and petroleum resin as base material of hot-melt road paint) in the substrate adhesion better, in the white varieties, the amount of titanium dioxide can less, better weather resistance. Usage: 1 can use K-A81 as base material individually; 2 can be used with petroleum resin and.

We used in powder coating, improve leveling, enhanced adhesion to substrate. Usage: in epoxy powder coatings, K-A81 substituted 5%-15% with reactive resin.

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Guangzhou Jut chemical science and Technology Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13925068566 |

| Contact: | Yong Wang (general manager) |

| Last Online: | 07 Aug, 2018 |