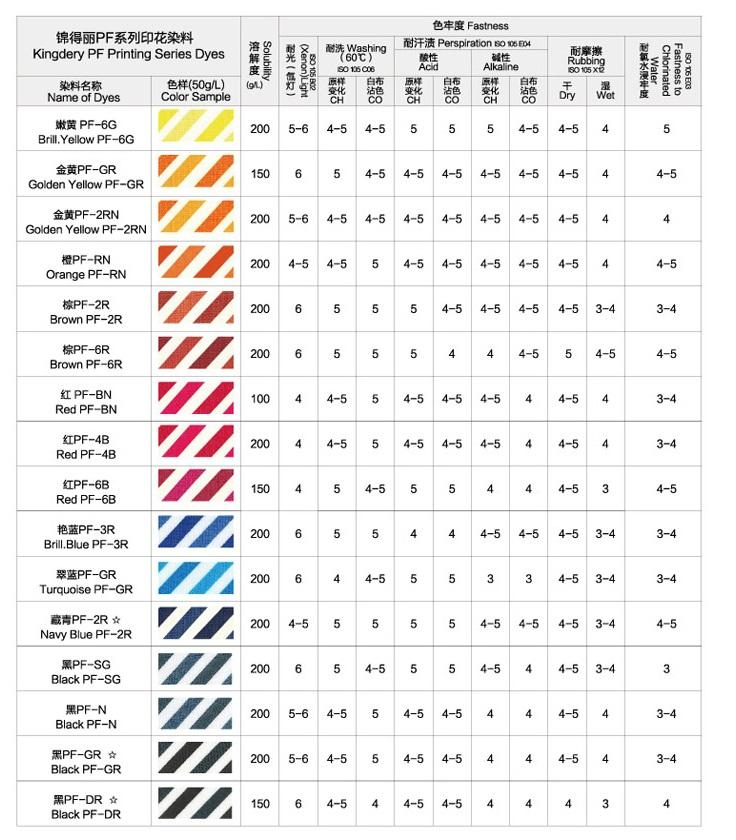

Kingdery PF series is Division I and printing dye, the dye has a high solubility series, fixation and promotion rates, and excellent and color fastness. Printing paste stability, tolerance of large granular superior solubility is more suitable for automatic pulp machine, suitable for fiber-based and continuous textile printing and dyeing.

Dye printing process when using Kingdery dye printing volume, alkali agent is usually baking soda, soda ash can also be used when printing dark alkaline agent.

A pre-treatment to achieve optimal printing results. The need to strengthen the fabric and pre-treatment. And removing residual contaminants within the fiber (such as oil, wax, pectin and other additives), these impurities hamper Stock hair dyes and cellulose fibers and an adverse effect on the reaction or to.

If the cotton was light or caustic solution treatment at not less than 22 ° Be (16%) of concentration, then the fabric can get the best color yield, brightness, leveling and wet rubbing fastness. Renewable cellulose fibers preferably 6-8 ° Be (4-5%) caustic soda solution treated condition in the absence of tension. In addition, pre-treatment can enhance the stability of the base cloth-like dimensions, but also improve the printing and washing effect.