| Model: | D3 |

|---|---|

| Brand: | baoyi |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metal Mineral |

| Label: | alloy steel , Cr12 , D3 |

| Price: |

US $1400

/ ton

|

| Min. Order: | 10 ton |

Product Description

Products description

D3,Cr12 Steel

D3 tool steel is a 12% chrome steel, it has very high wear resistance against abrasive and adhesive wear due to the high volume of hard carbides in the steel matrix, medium toughness, dimensionally stable, high compressive strength, not

secondary hardenable

The features

1. high carbon ang high chromium ledeburite steel.

2. High wer resistance,hardenability,strong toughness,termal stablity,the compressive,strength.

3 .Has high wear resistance, is a 3~4 times higher than average low alloy tool steel,quenching deformation small cabinet.

Applications

Highly stressed cutting and punching tools for thin sheets, profile rolls, drawing and deep drawing tools, stone processing tools, knives for paper and plastics, shear knives for thin sheets.

Chmeical Composition

|

Standard |

Steel Grade |

C |

Si |

Mn |

P |

S |

Cr |

V |

W |

other |

|

GB |

Cr12 |

2.00~2.30 |

≤0.040

|

≤0.040

|

≤0.030

|

≤0.030

|

11.50~13.00 |

|

|

|

|

ASTM |

D3 |

2.00-2.35 |

0.10-0.60 |

0.10-0.60

|

- |

- |

11.0-13.5 |

≤1.00 |

≤1.00 |

- |

|

JIS |

SKD1 |

1.90~2.20 |

0.10~0.60 |

0.20~0.60 |

≤0.030

|

≤0.030

|

11.0~13.0 |

≤0.030

|

|

|

|

EN |

X210Cr12 |

1.90-2.20 |

0.10-0.60 |

0.20~0.60 |

≤0.030 |

≤0.030 |

11.00-13.00 |

- |

- |

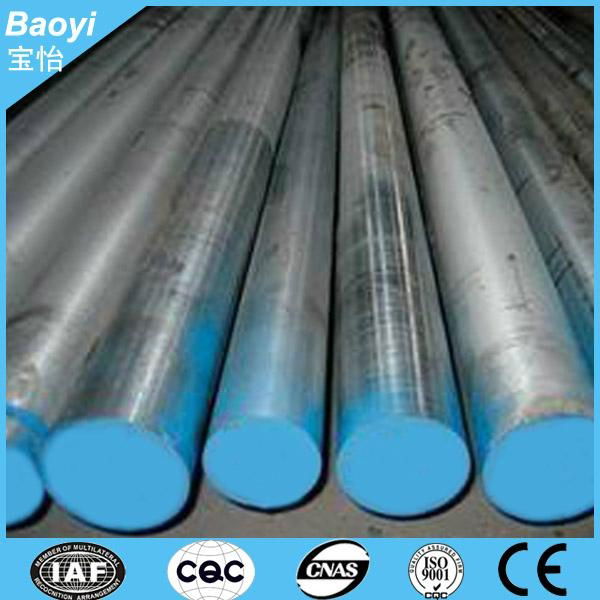

Specifications

|

Size |

round | Dia 18mm-220mm |

| flat | Thickness | |

| 20mm-400mm | ||

| Width | ||

| 60mm-600mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; tempered | |

| Surface Condition | Black surface ; Grinded ; Machined or based on your requirements. | |

| Delivery Condition | hot rolled ; cold drawn ; forged | |

Heat treatment

|

Hardness |

59-63HRC | - | |||||||||

| Anneal | 830-870°C | ≤269HB | |||||||||

| Quenching | 950-980°C | Air or oil cooling | |||||||||

| Tempering | 180-200°C | 60-62HRC, tempering once | |||||||||

| - It is annealed before ex-factory, which ensure good metallographic structure, proper hardness and good workability. There is no need to anneal again. | |||||||||||

| - But It must be re-annealed if reforged, as the original organization and performance are destroyed after reforged, and the forging stress increased. | |||||||||||

| - Normally it will be annealed twice and the temperature of the second annealed is 20°C lower than the first one.

|

|||||||||||

The relevent products

| Tool Steel | AISI(America) | JIS(Japan) | DIN(Germany) |

| Tool steel | H21 | SKD1 | 1.2581 |

| H11 | SKD6 | 1.2343 | |

| H13 | SKD61 | 1.2344 | |

| O1 | SKS3 | 1.2501 | |

| A2 | SKD12 | 1.2363 | |

| L6 | SKT4 | 1.2763 | |

| D2 | SKD11 | 1.2379 | |

| D3 | SKD1 | 1.208 | |

| D5 | 1.2601 | ||

| P20 | 1.2311 | ||

| 718 | 1.2738 | ||

| DC53 |

Shiping

You can no need to worry about packaging and shiping.Wuhan,Huangshi,Shanghai port is convenient for our company,We can choose the shipping port according to customers' requirements.

packaging

steel will sealed packing, arrived safely,without damaged,so you don't need worry about it,just trust us.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Our service

1.having more than 10 yesrs history in special steel, such as tool steel,spring steel,alloy steel,stainless steel ,etc.

2.being a professional manufacturer who can produce kinds of steel according to customers' requirements.

3. high quality,resaonable price.

4. put customers in the frist place.

5. our goal is to meet your ruquirements.

please keep contact with me timely :

whatsapp:086-13409889816

skype:pennywang

| Payment Terms: | T/T ,LC |

|---|---|

Member Information

| Huangshi Baoyi Materical Co.,ltd | |

|---|---|

| Country/Region: | Hu Bei - China |

| Business Nature: | Trading Company |

| Phone: | 09889816 |

| Contact: | Penny (manger) |

| Last Online: | 13 Apr, 2016 |

Related Products of this Company

-

GCr15 ASTM52100 SUJ2/100Cr6

US $940

-

Astm 9260 Spring steel

US $430

-

good price structral steel 20Cr alloy

US $800

-

H13 /4Cr5MoSiV1 / SKD61 alloy tool steel

US $1700

-

Q345B /ASTM345 high strength steel

US $500

-

1010 high quality carbon steel

US $800

-

Spring steel bar 51CrV4 1.8159

US $630

-

P20 die steel

US $1500

-

3Cr17NiMo Plastic Mould Steel

US $1400

-

D5 alloy tool steel die steel mould

US $1060