| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Energy / Petroleum |

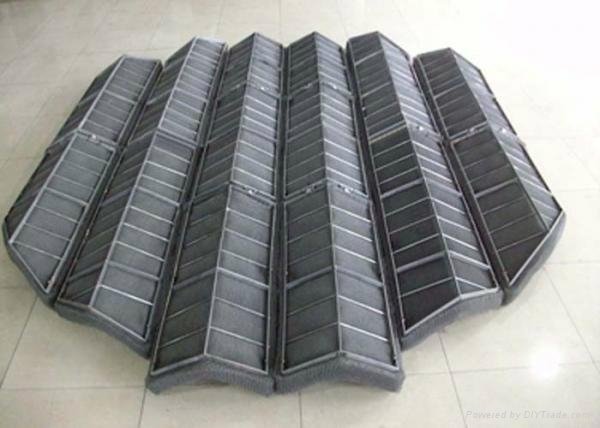

| Label: | wire mesh demister , mist eliminator , demister pad |

| Price: |

-

|

| Min. Order: | - |

Product Description

A demister, or also known as mist eliminator, is a high efficiency separation device often fitted to vapor liquid separator vessels to enhance the removal of liquid droplets entrained in a gas or vapor stream. Demisters may be a mesh type coalescer, vane pack or other structure intended to aggregate the mist into droplets that are heavy enough to separate from the vapor stream.

Mist eliminators/ demisters are fabricated from knitted materials with interlocking asymmetrical loops of metal or plastic with typical diameters being 0.1 – 0.3mm. Special applications for wire diameter 0.35mm to 0.024mm, tube width 1/4" to 42" diameter.

2.DEMISTER Materials:

Stainless Steel wire: 200, 300 and 400 series-AISI201、202、301、302、304、304L、321、316、316L,410S, etc.

Copper wire, Aluminium wire, Nickle wire, Titanium wire, Inconel, Monel, Hastelloy wire...

Plain Steel, Galvanized Steel...

Polypropylene, Polyethylene, PVC, Teflon(PTFE), Nylon, etc.

Stainless steel wire with cotton thread, fiber glass, etc.

3.FIXING METHODS&GRID

The demister should be horizontally fixed and supported. At the bottom or both the top and the bottom, a support grid which is welded with FB 25X3t, RB6Ø of the same material as that of the demister pad at proper intervals (APP150mm), is used. For fixing the grid and the pad, RB6Ø or 1.6Ø tie wire is used.

4.DEMISTER FEATURES (Mesh Pad type)

1).It shows 99% efficiency under general conditions and velocity (1~3m/sec or higher).

2). Over 98% open area is guaranteed under any conditions so pressure drop caused by the use of the demister can be disregarded (0.1”~1.0 W/G).

3). It can be made of any material suitable for the given temperature and corrosion-resistance.

4). It is possible to install by use of M/H so it is easy to handle.

5). There is no restriction in the conditions, place, and size for use. It is install-able on the existing systems.

6). Self-cleaning is possible. It is semi-permanent so it is economical.

5.USE OF DEMISTER

1).Vacuum Tower - The treatment quantity by the demister goes up by 35%. The quality of oil gas is improved.

2). Absorber - Some gasoline plants use a glycol absorber (Demister mounted) so the installation cost is being repaid within a month.

3). Knockout Drums and Separators - If Demister is used, ⅓inch drum is sufficient.

4). Gas Separator Vessels - Hydrocarbon in gases is collected so gas of 1/0.1 billion purity is produced out.

5). Evaporator - Product loss goes down and purity is remarkably improved.

6). Scrubber - In the field of caustic soda, the demister is used to prevent air pollution.

7). Distillation Column - If Demister is used, the cost for distillation goes up, the quantity of treatment increases by 20%, and purity is remarkably improved.

8). Dust Collectors - The dust collector of a wet type has excellent collection capacity.g is possible. It is semi-permanent so it is economical.

.

Mist eliminators/ demisters are fabricated from knitted materials with interlocking asymmetrical loops of metal or plastic with typical diameters being 0.1 – 0.3mm. Special applications for wire diameter 0.35mm to 0.024mm, tube width 1/4" to 42" diameter.

2.DEMISTER Materials:

Stainless Steel wire: 200, 300 and 400 series-AISI201、202、301、302、304、304L、321、316、316L,410S, etc.

Copper wire, Aluminium wire, Nickle wire, Titanium wire, Inconel, Monel, Hastelloy wire...

Plain Steel, Galvanized Steel...

Polypropylene, Polyethylene, PVC, Teflon(PTFE), Nylon, etc.

Stainless steel wire with cotton thread, fiber glass, etc.

3.FIXING METHODS&GRID

The demister should be horizontally fixed and supported. At the bottom or both the top and the bottom, a support grid which is welded with FB 25X3t, RB6Ø of the same material as that of the demister pad at proper intervals (APP150mm), is used. For fixing the grid and the pad, RB6Ø or 1.6Ø tie wire is used.

4.DEMISTER FEATURES (Mesh Pad type)

1).It shows 99% efficiency under general conditions and velocity (1~3m/sec or higher).

2). Over 98% open area is guaranteed under any conditions so pressure drop caused by the use of the demister can be disregarded (0.1”~1.0 W/G).

3). It can be made of any material suitable for the given temperature and corrosion-resistance.

4). It is possible to install by use of M/H so it is easy to handle.

5). There is no restriction in the conditions, place, and size for use. It is install-able on the existing systems.

6). Self-cleaning is possible. It is semi-permanent so it is economical.

5.USE OF DEMISTER

1).Vacuum Tower - The treatment quantity by the demister goes up by 35%. The quality of oil gas is improved.

2). Absorber - Some gasoline plants use a glycol absorber (Demister mounted) so the installation cost is being repaid within a month.

3). Knockout Drums and Separators - If Demister is used, ⅓inch drum is sufficient.

4). Gas Separator Vessels - Hydrocarbon in gases is collected so gas of 1/0.1 billion purity is produced out.

5). Evaporator - Product loss goes down and purity is remarkably improved.

6). Scrubber - In the field of caustic soda, the demister is used to prevent air pollution.

7). Distillation Column - If Demister is used, the cost for distillation goes up, the quantity of treatment increases by 20%, and purity is remarkably improved.

8). Dust Collectors - The dust collector of a wet type has excellent collection capacity.g is possible. It is semi-permanent so it is economical.

.

Member Information

| hebei mada metal wire mesh trading co.,ltd | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Trading Company |

| Phone: | 15831965902 |

| Contact: | janny lui (sales manager ) |

| Last Online: | 04 May, 2016 |