Air Cooler is taking more market shares between fans and air conditioners, the price is expensive than fan but cheaper than air conditioners. And compared air conditioner, it is much environmental, no need Freon.

People put the ice water in the water tank, and take on the blower,there will come the cooling wind.

So, the air cooler molds are much popular and tightly needed in plastic molds manufacturing line. Normally, the customer will develop 30L air cooler and 60L air cooler molds. The covers and louver blades can be shared, only change the water tank molds.

Sino Mould have rich experience in making air coolers molds. Mold steel for shiny surface is DIN1.2738, If mat surface or printing surface, the mold steel can be 718H. Hot runner molds are s ested for better injection and sometimes timing valve gate is applied to solve injection melting line.

Mold base is Sino Mould base or Measuring up to DME standard.

Mold standard parts is Misumi or DME standard

Delivery time is 90 days from order confirmation.

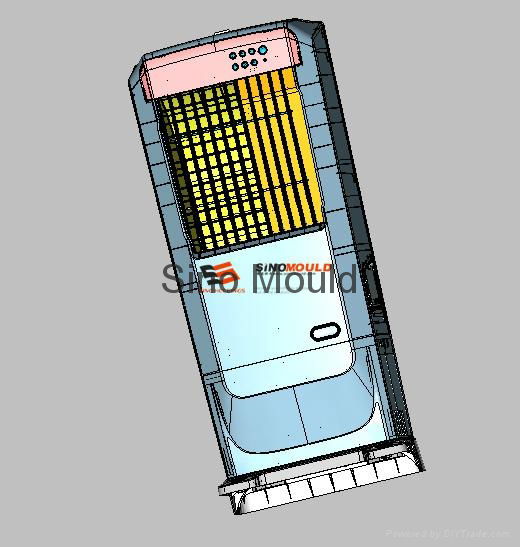

Air cooler molds included below main molds: Front mold, back mold, filter mold,panel mold, water tank mold, H louvers mold, V louvers mold, blower mold, blower cover mold, base or tray mold.

Some customer will choose high gloss mold surface; some will choose textured mold surface and some will choose painting product surface. Sino Mould can quote the mold price as different product's requirments.

Till Now, we have made molds for Midea,Hisence,Ghigo,Galanz, and some foreign local brands in Iran, UAE, Egypt.

If you are interested to cooperate with us, welcome to contact us