| Model: | 006 |

|---|---|

| Brand: | vanna |

| Origin: | Made In China |

| Category: | Chemicals / Inorganic Chemical Materials / Oxide |

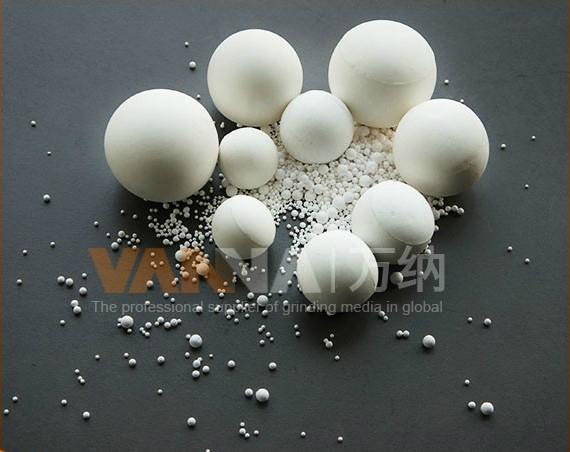

| Label: | Alumina Ball , High Alumina Ball , Alumina ceram ball |

| Price: |

-

|

| Min. Order: | 1 ton |

Product Description

- Material: Alumina Ceramic, ceramic

- Model Number: Customer's Requirements

- Brand Name: VANNA

- Item: VANNA92

- Name: Alumina ball 92% oxide in ceramic

- Color: white

- Certificate: ISO9001

- Wet method(%): ≤0.005

- Size: Customer requirements

- Certification: ISO9001:2008

- Product: Alumina grinding ball

1. Features:

grinding media is characterized by:

(1)Higher density;

(2)Higher hardness;

(3)Higher wear resistance;

(4)Higher grinding efficiency.

2. Application:

(1)Use in high speed stirred grinding mills in mining applications.

(2)Ball mills as abrasive media for ceramic raw materials

(3)Glaze materials in ceramic factories, cement factories, enamel factories

(4)Glass work owing to the excellence of high density, high hardness, and high wear rate.

during the abrasive/grinding processing, ceramic balls will not break up; it will not pollute the grinded material as well.

(5)The mix and crush procedure of ceramics, glass, glaze and frits, chemical and plastic industries.

3. Method of application:

(1)Using in wet grinding method:

A. Final Assembly of ball in ball mills a total volume of 55%.

Empirical formula: M=3.14*R2*D*L*25%/1000

(Note: M= charged alumina ball quantity number of added alumina balls

D= alumina ball density(g/cm3)

D= alumina ball density (g/cm3) density of alumina ball

R= radius of ball mill

RADIUS r = radius of ball mill ball mill

L= length of ball mill

Length l = length of ball mill ball mill)

For a new installation of ball mill, loading specifications and dimensions of the ball depends on the size and weight of the ball mill.

B. Increase volume of ball = Initial amount of ball*Wear rate*Grinding time

(2)Use in dry grinding methods:

Dry grinding is widely used in mining, ceramics, powders and other industries. Wear of grinding media for split industry pollution of raw materials, we developed the dry grinding ball of low toughness, wear, solves the grinding media of widespread pollution problems of raw materials.

Dry grinding with grinding ball ratio depends on the raw material of hardness and the grinding of rough, usually by isostatic molding grinding balls.

4.Specification:

|

Item type |

SNA

|

SNH

|

SNG |

|

|

Usage) |

Wet grinding |

Wet grinding |

Dry grinding |

|

|

Al2O3(%) |

92 |

95 |

99 |

|

|

Bulk density(g/com3) |

>3.65 |

>3.67 |

>3.63 |

|

|

Porosity |

0.00 |

0.00 |

0.00 |

|

|

Wear rate |

wet method(%) |

≤0.005

|

≤0.003

|

≤0.006

|

|

dry method(%) |

|

|

0.005

|

|

|

Hardness(M0hs) |

9 |

9 |

9 |

|

|

Color |

White

|

White

|

White

|

|

|

Diameter(mm) |

3~90 |

3~60 |

10~90

|

|

For further information:Alumina ball  http://www.vannarise.com/alumina-ball

http://www.vannarise.com/alumina-ball

Member Information

| Zibo Vanna trade co.,ltd. | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 2777757 |

| Contact: | Maria Ma (Manager) |

| Last Online: | 22 Apr, 2016 |

Related Products of this Company

-

alumina grinding ceramic ball

US $850

-

Wear Resisting Alumina Ball 92% Usded in

-

high quality alumina ceramic ball in

-

Low Price Alumina Grinding Ball For Ball

-

High Alumina Lining Brick

-

application of alumina balls in cement

-

high density alumina ball used in

-

92% Ceramic Grinding Cylinder for Ball

-

High density alumina ball

-

Gold Supplier Alumina Grinding Ball

US $850