| Model: | - |

|---|---|

| Brand: | fortune |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | pvc machine , pvc coating machine , pvc gypsum machine |

| Price: |

US $10000

/ set

|

| Min. Order: | 1 set |

Product Description

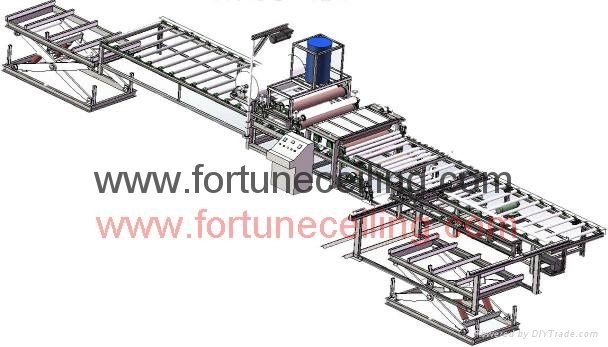

PVC/Fiberglass Felt coating production line :

FB-type board multi-purpose coating machine is a newly developed , a new generation of multi-function board coating machine, used in fireproof board, mineral fiber board, fiberglass board, gypsum board, plywood board, five ply wood board, particle board, MDF and other for surface coating, the machine is fully automatic intelligent computer program control, auto-complete on glue spreading, baking glue, coating, and coat cutting, through twice cold pressing and triple hot pressing. The machine can continuously produce, have high production efficiency,

The machine features: pneumatic unwinding, correction on loading ramps, adjustable speed, static elimination, automatic dust removal, adhesive, pneumatic hot and cold press, which is using new production technology operating procedures, effectivelly solving the paste not strong, bubbles, folds and other negative phenomena, so which can

also effectively improve the production efficiency, greatly reduce human resource

FB-type board multi-purpose coating machine:

Firstly, technical parameters

1: The maximum laminating width: 1320mm

2: plate thickness :3 --- 50mm

3: Production speed: electromagnetic speed (speed adjustable)

4: Air Source Pressure :0.4-0 .8 mpa

5: Drive power: 2.2kw

6: capacity: 13.5kw

7: Overall dimensions: 13000 × 1900 × 2100mm

8: Weight: 2100kg

Secondly, production process: load the board - automatic dust removal - automatic adhesive - infrared heat automatically baked plastic - Automatic coating- Automatic cold pressure - Automatic Hot pressure - Auto film cutter - Finished

Thirdly, the main structure

FB - 1320 board multi-purpose coating production is made up from filter (1), centrifuge (1 set), coating machine (1 set), the former transferring station (1 station),middle transferring station (1 unit),infrared thermal heated oven (2), film cover machine (1 set), pvc heat infrared heating oven (1) latter transferring station (1 station), controlling panel (1 units)

1: coating machine: between the former transfer stations and latter transfer station,

2 the former transfer station: in front of coating machine, with automatic dust removal system.

3:middle transfer station: behind the coating machine, equipped with two infrared heat oven .

4: film cover machine: between former and latter transfering station, equiped with pvc preheating equip

5:latter transfer station: behind the coating machine

6: controlling panel: nearby the middle transfer station, used to control the entire production line speed.

Automatic Cutting Machine

FB-a automatic plaster ceiling cutting machine is newly developed which has high degree of cutting automation, a ceiling can be divided into 8 cut block, size adjustable. With a central console, 5.5kw power dust centrifuges, host dust cover. The machine has the advantages of continuous production, accurate cutting, high cutting efficiency, no dust and so on.It is the first choice for ceiling manufacturers, and decorative board companies for the usage of cutting

Tech data

|

Dimension |

1250, 2440mm |

Saw power |

1.5K*8=12KW |

|

Speed |

12m/min |

Transmission power |

6.75kw |

|

Thickness |

5-20mm |

Dust centrifuge power |

3kw+4kw=7kw |

|

Saw diameter |

305mm |

Full power |

26kw |

|

Saw aperture |

42mm |

Power source |

380V 50Hz |

|

Saw speed |

2850r/min |

Length height width |

8800*4200*1300mm |

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Fortune New Building Material Co., Ltd | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 13313316090 |

| Contact: | Zhang (Sales Manager) |

| Last Online: | 28 Jun, 2016 |

Related Products of this Company

-

WPC line wood plastic composited panel

US $100000