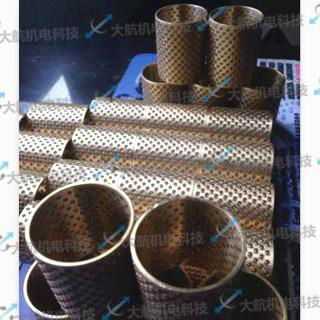

Our main products have: D BGS Miniature Ball Bearing Guide bushings(ball bearing cage), D BGZ Miniature Ball Bearing Guide Sets, ball Guide bushings, JDB inlaid solid lubricating bearings, D SF composite bearing lubrication bushings, D FB bronze bearings, D JF bimetal bearings, etc.

Our company independent research and development in the field of automatic continuous production line,

upon bulk production, on Miniature Ball Bearing Guide bushings, we have Ball dia 1mm series, 0.8mm series, 0.6mm series; we have the shaft dia, 2mm,3mm,4mm,5mm,6mm,8mm,10mm,12mm, etc, and various length of Miniature Ball Bearing Guide Sets.

Used for precision and high requirements of the mechanical structure. Especially suitable for linear motion, in the aspect of life and transmission accuracy is beyond other product. As different purposes, we can provide various of standard and non-standard types. We currently produce the min specifications as: min diameter of shaft: 2mm, min ball diameter: 0.5mm. According to the density of ball arranged, we will be divided into two types: standard and compact (thin wall type).

The products also can be made according to "MISUMI", "FIBRO", "PUNCH", "DANLY", "DME", "HASCO", "TOHATSU", "AGATHON", "STRACK", "PEDROTTI", "RAYMOND", "FUTABA", "SANKYO", "PROGRESSIVE", "RABOURDIN", etc., or as customers' drawings.

Process:

Ball guide bushing: Sawing material- Lathing (CNC Lathe or Common Lathe)- Drill on bushing- Polishing- lock ball.

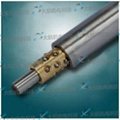

Shaft sleeve: Sawing material- Lathing (CNC Lathe or Common Lathe)- Heat Treatment- Sand Blasting- Grinding (Rough internal grinding)-Honing (Precision Honing)-Grinding (Rough or accurate grinding)- Grinding (Precision Centerless Grinding)

Shaft: Sawing material- Lathing (CNC Lathe or Common Lathe)- Heat Treatment- Sand Blasting- Grinding (Rough internal grinding)-Honing (Precision Honing)-Grinding (Rough or accurate grinding)- Grinding (Precision Centerless Grinding)