| Model: | DN |

|---|---|

| Brand: | LUY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | wooden pole treatmen , impregnating wood m , vacuum pressure woo |

| Price: |

US $10000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Product Description

Professiomal automatic plant for pressure impregnated wood apply to wood’s corrosion protection, fire retardant, mothproof, fire prevention, insect-resistant, modification, dyeing, coking, degrease and deep processing. Wide applicability, better effect of processing, big capacity. reasonable layout, safety and reliable are the advantages of this equipment. And it also have advantages of reduce labor intensity and working cost. It completely meet the requirement of deep processing of all kinds of wood.

| Model | Capacity/ stere | Treat capacity/ stere |

| DN 1200*4000mm | 4.6 | 3.0 |

| DN 1200*6000mm | 6.7 | 4.5 |

|

DN 1200*8000mm |

9.0 | 6.0 |

| DN 1500*4000mm | 7.0 | 4.71 |

| DN 1500*6000mm | 10.5 | 7.0 |

| DN 1500*8000mm | 14 | 9.4 |

| DN 1700*4000mm | 9.0 | 6.0 |

| DN 1700*8000mm | 18.1 | 12 |

| DN 1800*4000mm | 10.1 | 6.78 |

| DN 1800*6000mm | 15.2 | 10.17 |

| DN 1800*8000mm | 20.3 | 13.5 |

| DN 2000*6000mm | 18.8 | 12.5 |

| DN 2000*8000mm | 25 | 16.7 |

| DN 2000*10000mm | 31.4 | 20 |

| DN 2000*18000mm | 56 | 37 |

Detailed Images

Technology

1. Initial vacuum: we need to keep the tank vacuum before filling of the wood preservative. And it will make the wood preservative into wood cells better. The vacuum degree is -79.8~90kpa and the vacuum time is according to different product(normally 15-60 minutes). when the cylinder in vacuum state, a part of air in the wood was taken out, the resistance will reduce when the wood preservative pushed into wood, so the wood preservative will be easy to get into wood cell.

2. Filling of preservative into tank: Add the wood preservative by manual valve when the equipment in vacuum state, to make sure the air which in the same condition was stopped in the wood cells. (the degree of vacuum is up to the size of valve)

3. Boost pressure stage: Begin to boost pressure lowly to 1.0-1.4MPa when the preservative is full of wood tank ,then keep the pressure value until the regulation preservative into the wood.

4. Pressure relief and discharge preservative: Discharge the pressure after the regulation preservative is absorbed. There will be a little recoil phenomenon(5-15%) during the process.

5. Final vacuum: Pumping air from the tank to keep the tank vacuum after the preservative discharged from the tank. The purpose is to extract excess wood preservative to reduce the phenomenon of oil dripping.

6. Recover atmosphere, then open the door and take out of timbers.

Packaging & Shipping

Customer visit

Company Information

We have three production lines to meet customers’ requirements ,more than 20 senior engineers to design ,skillful welder to process the equipment ,24hours after-sales team to support. Our products have been sold to Russia, French, Peru, Uganda, Tanzania, Kenya and Burma.

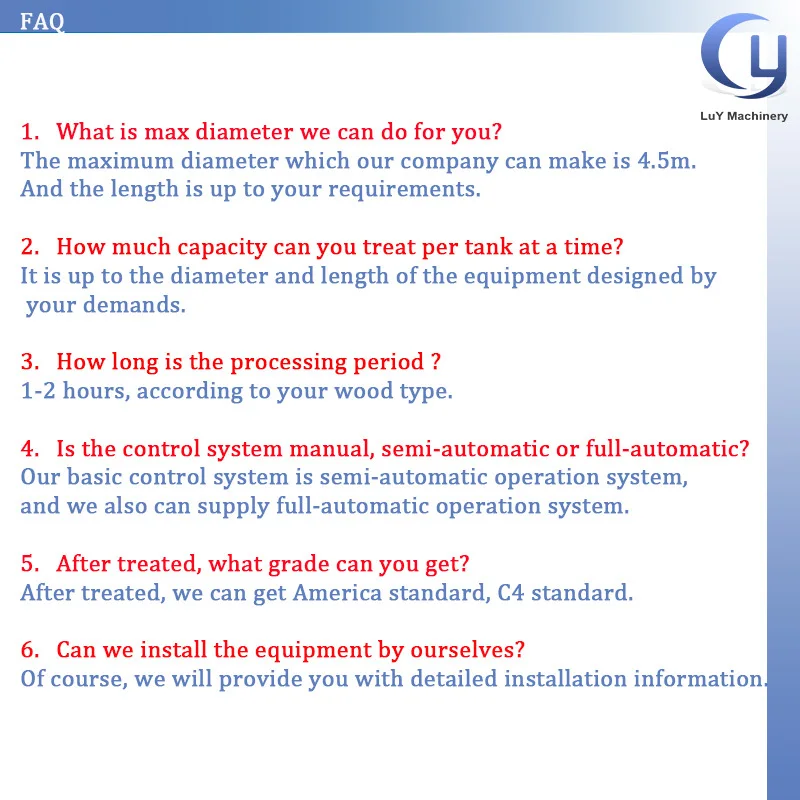

FAQ

Contact us

Member Information

| Henan Luy machinery equipment CO.,LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15500580520 |

| Contact: | Emma He (Manager) |

| Last Online: | 20 Nov, 2015 |

Related Products of this Company

-

Thermo wood treatment plant

US $12000

-

Full automatic food sterilization

US $8800

-

Full automatic composite autoclave for

US $15000

-

Wood vacuum drying equipment

US $15000

-

Automatic thermo wood machine

US $47770

-

Full automatic tire curing chamber

US $15000

-

Full automatic autoclave for carbon

US $158000