| Model: | RX-004 |

|---|---|

| Brand: | Rongxin |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-metallic Mineral Products |

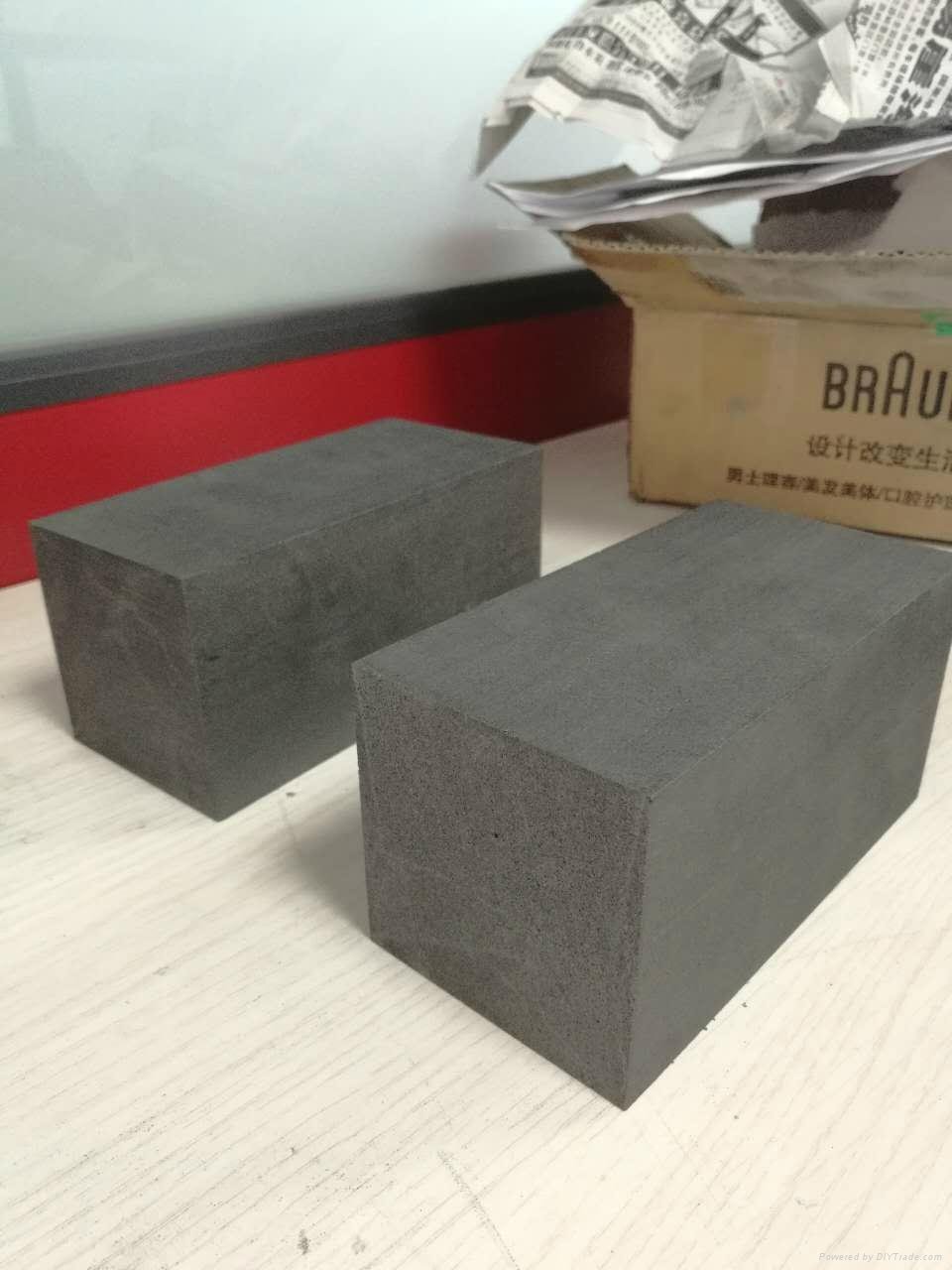

| Label: | graphite block , carbon block , graphite brick |

| Price: |

US $1800

/ Ton

|

| Min. Order: | 10 Ton |

Product Description

Quick Details

| Place of Origin: |

Henan, China (Mainland) |

Brand Name: |

RongXin Carbon |

Model Number: |

RX-004 |

| Application: |

Metallurgy |

Dimensions: |

Requirements |

Chemical Composition: |

Carbon |

| Material: |

High Pure Graphite Materials |

Shape: |

Square |

Compress strength: |

34Mpa Min |

| Density: |

1.7-1.78g/cm3 |

Bulk Density: |

1.80g/cm3 |

Color: |

Black |

| Ash content: |

0.1% Max |

Flexural Strength: |

17.5Mpa |

Key word: |

Heat Sink |

| Appearance (form): |

Transparent |

Packaging & Delivery

| Packaging Details: | packing by plastic case and wooden pallets or as per customer requirement |

| Delivery Detail: | Shipped in 10 days after payment |

Product Description

|

Item |

Unit |

SLTA Ensure Value |

Reference Standard |

|

Bulk Density |

g/cm³ |

1.70 |

YB/T119-1997carbon material bulk density measurement method |

|

Ash |

% |

≤14 |

YB/T5146-2000 high purity graphite products with the determination of ash content |

|

Show Porosity |

% |

≤18 |

YB/T908-1997carbon material porosity determination method |

|

Compressive Strength |

MPa |

35 |

GB1431-85carbon material crushing strength method |

|

Linear Change Rate |

% |

±0.1 |

YB1910-2000self bakingcarbon block of roasting reduction method |

|

Flexural Strength |

MPa |

12 |

GB/T3074.1-1982 graphite electrode determination of flexural strength method |

|

Hot Metal Corrosion Index |

% |

28 |

YB/blast furnace molten iron corrosion index of 4036-1991 test method |

|

Oxidation Rate |

% |

12 |

YB/T5292-1999 test method of blast furnace carbon blocks |

|

Porosity |

mda |

9 |

GB/T9973-1988 carbon material porosity test method YB/T5391-1999 |

|

Coefficient of thermal conductivity |

W/m.k |

12 |

The blast furnace carbon block coefficient of thermal conductivity test method |

|

14 |

|||

|

15 |

|||

|

Alkali Resistance |

U/LC/C |

U |

YB/T5213-1993blast furnace carbon block alkali resistance test method |

Specifications:

1. Density: 1.55g/cm3-1.85g/cm3

2. Grain size: 8mm, 4mm, 2mm, 0.8mm, 325mesh.

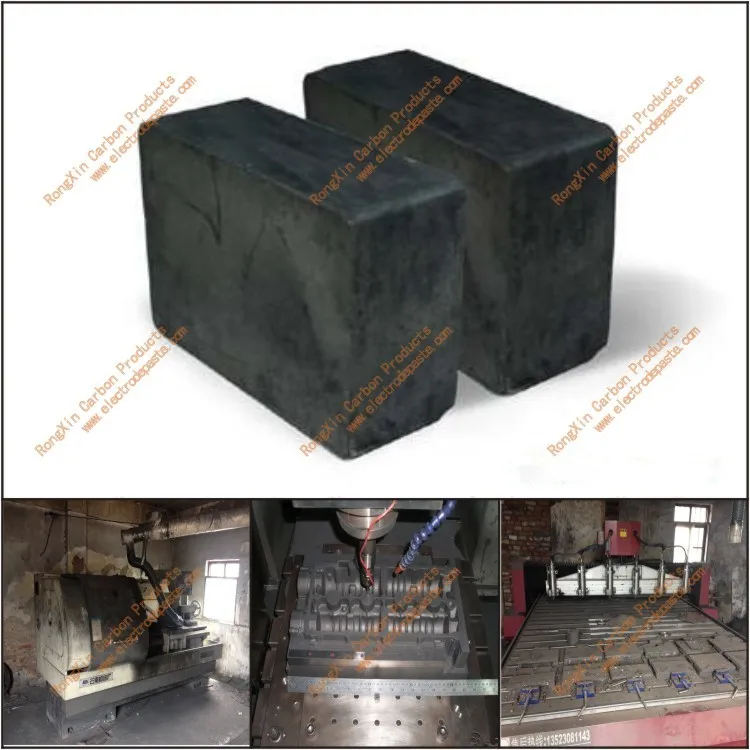

3. Production: Isostatic, molded, extruded, vibrated.

Product Introduction

Various sizes high pourity graphite carbon block

Graphite block is made form the domestic petroleum coke and widely used in the metallurgy, machinery, electronics and chemical industry, etc. The graphite block include molded, extruded, vibrated and isostatic. Our main and most preponderant graphite block is molded formed. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy and so on.

More sizes please feel free to contact us!

Application

Carbon brick raw materials including anthracite coal, coke and graphite, and combining with agent such as asphalt, tar and anthracene oil. Less volatile anthracite, dense structure, the production of carbon brick more to it as the aggregate, to join the metallurgical coke, coal tar, asphalt binder.

Thermal stability of carbon brick, small expansion coefficient, high temperature resistant, resistant to all kinds of acid, alkali, salt and organic solvents, but easily oxidized in the oxidizing atmosphere.

Producing Progress

All of our graphite block is made from the superior petroleum coke, which meets the state stands YB/T408-200. The better raw material will produce the better products.

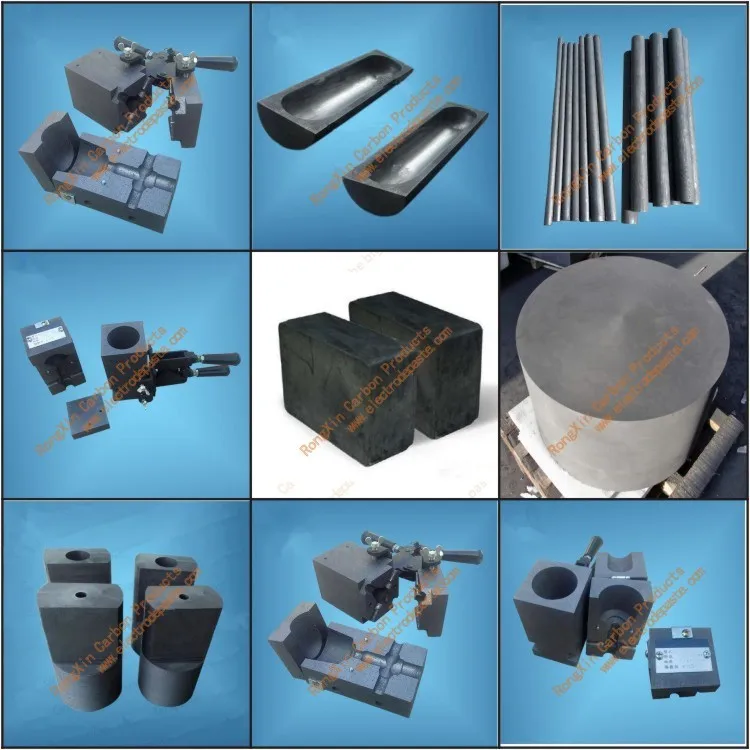

The graphite block can use for making graphite plate, graphite rod, graphite tube, graphite crucible, graphite rotor and shaft and so on. It widely used in electron industry, chemical industry, mechanical industry, aviation industry, manufacturing industry, metallurgic industry and so on, such as anode, cathode, bipolar plate, vacuum furnace, water treatment, hydrogen fuel cell, electrode, casting, glass factory, heat conduction, lubricant, mold industry, vacuum pump.

Why Choose Us

1, the company professional to do carbon and solid fuels

2, the quality of solid fuel and production is the biggest supplier in middle of China.

3, stable product quality , supply, the good faith management.

Product Packaging

Do you know how to choose the graphite block?

I think how to choose the graphite block is the hardest problem to our customers. According to our experience, most our customers don’t know the graphite very much, especially the specification, such as density, grain size, electric resistance, strength and so on.

The density and grain size are the most important specification, because the grain size will influence the density and density will influence all the specification. The higher density will produce the better products and with the higher price. The price must be in direct proportion to the quantity.

If you know the graphite and its specification very much, you could choose the best material according to our offered information.

If you don’t know the graphite and its specification very much, please kindly contact me. Then I will give you the best s estion.

Some information need to be confirmed, such as size or drawing, use, working environment, in vacuum or air, working temperature and so on.

Looking for ward to your early contact.

Contact by

Member Information

| GONGYI RONGXIN CARBON PRODUCTS CO., LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15333826131 |

| Contact: | WILLIAM (MANAGER) |

| Last Online: | 08 Mar, 2016 |