| Model: | 35*3.5 |

|---|---|

| Brand: | Yingyuanxin |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Stainless Steel |

| Label: | tube for boiling , tube for heat , heat exchange tube |

| Price: |

US $3.1

/ kg

|

| Min. Order: | 850 kg |

Product Description

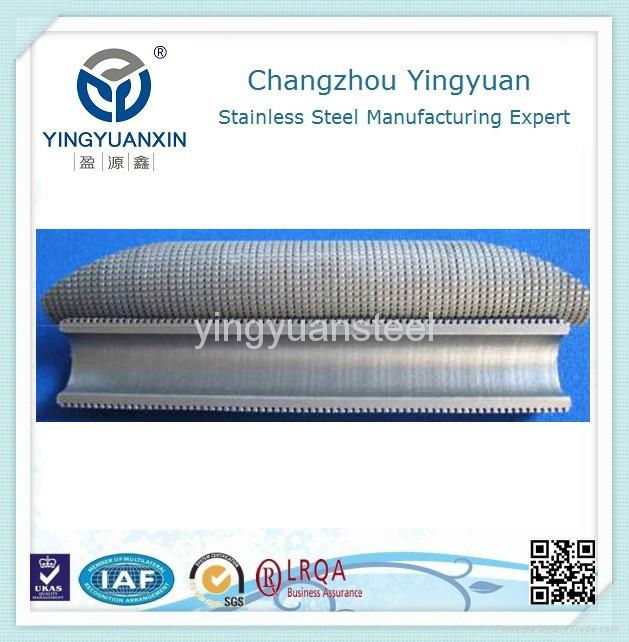

Extensive use of liquid in the field of oil refining and petrochemical boiling heat transfer process and equipment, the equipment investment and cost of energy is very considerable.Therefore, improving the boiling heat transfer efficiency to improve the technical level of equipment, reduce energy consumption, reducing equipment volume and stable long term operation, has important practical significance.In 2003, the company independently developed porous surface machining pipe - MH, (patent number: ZL20920193165, X) and cooperation with tianjin university school of mechanical engineering department of thermal engineering, a variety of specifications for boiling heat transfer performance test of MH pipe, as well as industrial light pipe and contrast test of t-shaped fin tube.Results show that single tube and tube bundle of MH tube of boiling heat transfer performance, not only is far better than the ordinary industrial light tube, than the current widely used T tube fin strengthening also have greatly improved.

Porous surface machining pipe - MH enhanced boiling heat transfer is the main way of the

(1) to strengthen the surface of the lateral surface of the convective heat transfer

(2) to strengthen the outside air bubbles away the gasification of latent heat

(3) strengthening the internal porous surface channel and liquid film evaporation.

The geometrical characteristics of the porous surface is narrow, groove depth, bidirectional hole spacing and density of cavity determines the reinforcement result.After lots of tube type geometry size of comparative screening test, are recommended for industrial application of optimum tube type of MH - 0.3 type.Test results show that porous surface strengthening MH - 0.3 type machining tube (water and ethanol as boiling medium), the intensity is equal to 10 exponent (4) ~ 1.7 * 10 exponent (5) W/m2 (square) within the scope of the boiling heat transfer coefficient respectively, 2 ~ 4 times of ordinary industrial light tube, is now commonly used industrial t-shaped fin tube of 1.5 to 2.0 times.MH tube compared with t-shaped fin tube, its advantage lies in shallow depth and processing surface groove, but because of the surface porous, makes heat transfer increased significantly, while maintaining the strength of the pipe with good.

At present the product has been applied in petrochemical industry tens, deeply user welcome.Horizontal reboiler composed of MH tube is a kind of high efficiency, low investment of new energy-saving equipment.Very suitable for new and potential in transformation in petrochemical units, provides a new way for energy conservation.

| Payment Terms: | T/T 30% for deposit, T/T 70% against B/L |

|---|---|

Member Information

| Changzhou Yingyuan Metal Materials Co., Ltd. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 15295077185 |

| Contact: | Felix Z (Sales Manager) |

| Last Online: | 07 Jun, 2016 |

Related Products of this Company

-

U-shaped Stainless Steel Pipe

US $3.2

-

Capillary Stainless Steel Tube

US $3.5

-

Stainless precision steel pipe used for

US $2.6

-

Horizontal stripes corrugated tube for

US $3.1

-

High Precision Seamless Stainless Steel

US $3.8

-

Stainless steel thin-wall tube and pipe

US $2.6

-

Cold rolled silvery round stainless

US $3.1

-

Schedule 40 high precision mirror

US $3.2

-

Cleanness inside wall precision

US $2.1

-

Spiral corrugated pipe for heat transfer

US $3.1