| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Pumps Vacuum Equipment |

| Label: | mirrorvacuum machine , mirror makingmachine , perfume bottle coat |

| Price: |

US $32000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Quick Details

- Condition: New

- Type: Coating Production Line

- Substrate: Glass

- Coating: Vacuum Coating

- Place of Origin: Hunan, China (Mainland)

- Brand Name: Hongfeng VAC

- Model Number: SP-1400

- Voltage: 380V

- Power(W): 65KW

- Dimension(L*W*H): 5*4*3 meters

- Weight: 5 TONS

- Certification: CE

- Warranty: 1 YEAR

- After-sales Service Provided: Engineers available to service machinery overseas

- Equipment Name: vertical type vacuum machine to metallise plastic part

- Chamber Size: Following customers' demands

- Coatngs: Si, Stainless steel, Al, Cu

- Automatic Grade: Automatic, manual

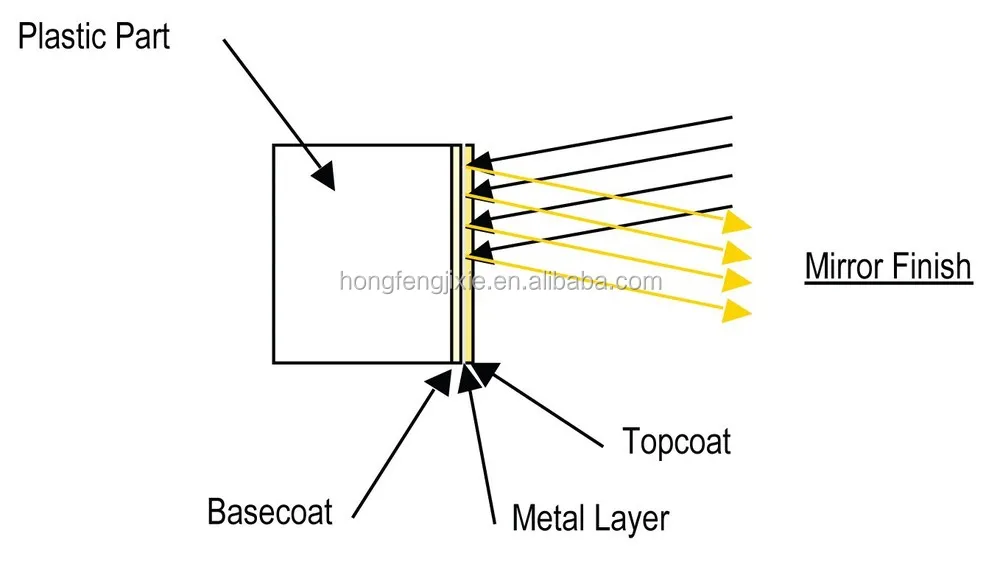

- Technology: Physical vapor deposition

- Method of Coating: Magnetron Sputtering

- After sales Service: Free Operation training

- Sampple: For free

- Installation: We send skillful engineers if required

- Inspection Place: In Seller's Factory

Packaging & Delivery

| Packaging Details: | Export Standard Packing |

|---|---|

| Delivery Detail: | Shipped in 60 days after payment |

vertical type vacuum machine to metallise plastic part

Technical Specifications:

| PVD(physical vapor deposition)Metal Coating Machinery

Evaporation Aluminum Metallizing machine (The configurations are custom made to meet each customer's needs) |

|||||||

| Available coatings | Metal film coatings: Aluminum and other easy-melting metal | ||||||

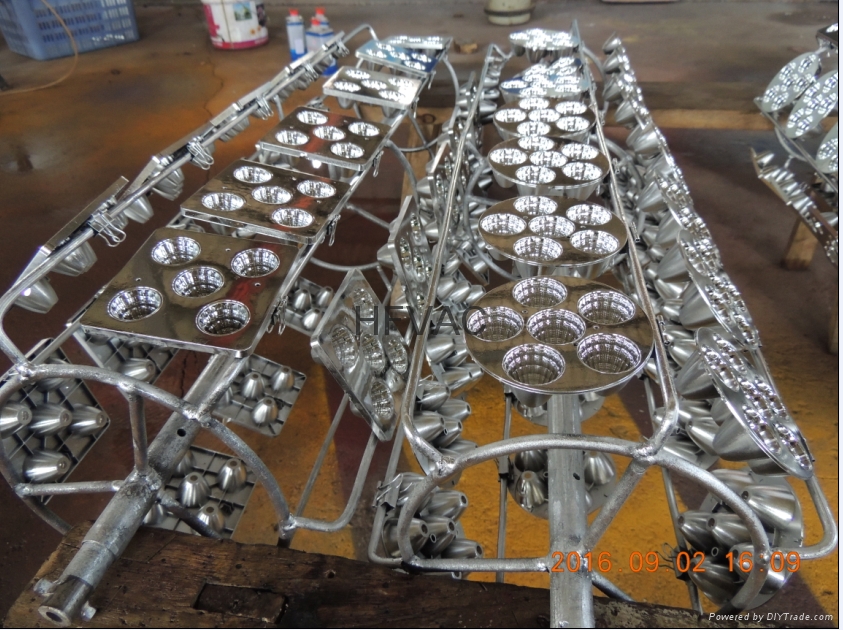

| Applications | |||||||

| 1. Plastic metallization

3. Mirror making 4. Car parts coating 5. Cosmetic caps coating 6. Glass chatons Decorative thin film coating onto other items. |

|||||||

| Model Number | EV-1000 | EV-1200 | EV-1400 | EV-1800 | EV-2000 | Two doors or Two chambers model are available | |

| Dimension of vacuum chamber(diameter*height) | 1000*1100 | 1200*1400 | 1400*1600 | 1800*2000 | 2000*2200 | ||

| Material of vacuum chamber | Carbon steel, SUS304 or SUS316L | ||||||

| Technology of working | vacuum resistance evaporation with tungsten& aluminum filaments, high power evaporation transformer | ||||||

| Pumping system | Diffusion pump+mechanical pumps, booster pump | ||||||

| Pumping Time | From atmosphere to 5.0*10-2Pa less than 8 minutes | ||||||

| Vacuum Limit | 5.0*10-4 Pa | ||||||

| Working temperature | Room temperature | ||||||

| Working mode | Automatic or Manual mode, by 10.4 inches PLC touches screen | ||||||

| Total Power | 40-80kW | 70-140kW | |||||

| Footprint | 2*2 meters | 2*3 meters | 3*3 meters | 3*3 meters | 3*4 meters | 4*5 meters | 5*6 meters |

| These units you can custom made | 1. Size of vacuum chamber

2. Configurations of pumps |

||||||

| Optional instruments | 1. Leakage detector

3. Arc ion deposition system 4. Magntron sputtering system |

||||||

| The videos of running machine on youtube.com | |

| Holders/Jigs | https://www.youtube.com/watch?v=GJwv1QH2oWg |

| Loading the aluminum filaments | https://www.youtube.com/watch?v=9tySedu_YcU |

| To make the base varnish/topcoat uniform | https://www.youtube.com/watch?v=1-1HbQUjiJk |

| Put the products after base varnish into the oven | |

| vacuum metallization(or by sputtering: https://www.youtube.com/watch?v=_7PDjJ8OHLY) | |

| Coloring after vacuum metallization | https://www.youtube.com/watch?v=ftzAjFFqmCM |

| Remove the extra coloring liquid | https://www.youtube.com/watch?v=i6m60d86Tsw |

| Topcoat | https://www.youtube.com/watch?v=QMpipvZihRQ |

| Remove the dusty and then apply the base vanish before vacuum metallizing | https://www.youtube.com/watch?v=FaRF4kH8wlw |

| Base varnish for wheel covers | https://www.youtube.com/watch?v=aGtYyv8G3lc |

|

PVD coater for car wheels

|

https://www.youtube.com/watch?v=7MCOnM3-FD0

|

Before sales:

- Our engineers are ready to provide custom made design and recommendation for each customer's case.

- We provide professional consulting service for PVD coaters and lines.

- We also have set up good relations with the suppliers of relative consumables and parts for your needs.

After-sales

- We will send the engineers to your place for installation, fine tune and for operation training.

- We will provide troubleshooting service all lifetime.

- The warranty period of the machine is 1 year.

- We will contact you to ask for about the conditions of the machine in periodically.

- We also provide the service for further extension on your existing machine.

FAQ

Question 1: I am going to set up a new factory. I don't know anything about the machine. Will you provide the technical support?

Answer: Sure. Every machine will be test before delivery. We will make sure there is no problem for the machine.

You may send 2-3 smart workers to come to our factory to learn how to operate the machine.

When the machine arrives your factory, we will send the experts to your factory to help for installation. Operation training will be provide. It may take about 20-30 days. Maintenance tips will be given.

Also, we provide consulting service for creating the proper facilities for running the machine.

Question 2: What is price of the machine?

Answer:

The machine is custom made. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please tell us the max. dimension of your products, its application, and your desired daily capacity.

We will provide our professional s estions and work out an appropriate design for your project.

Question 3: What kind of pre-treatment I need to do before the vacuum PVD process?

Answer: In vacuum area, the products(we call it"substrate") have to be CLEAN, DRY AND SMOOTH. So we will need washer and dryer, sometimes base varnish, and topcoat to protect the coatings.

Question 4: Do I have to pay the costs for pollution?

Answer: The machine is environment-friendly, there is no liquid chemical waste and harmful gas. This is a kind of green technology.

Inquiry Guides

Dear Customer: :-)

Good day.

When you are going to send us a inquiry, in order to design the most appropriate machine for your project, please answer the following questions in your letter:

1. What is your product, its material and application

2. What is the possible max. dimension of your product

3. What is your desired productivity per 8 hours/shift.

The answers to the above question will help us a lot on designing or do the recommendation.

Member Information

| Xiangtan Hongfeng mechanical equipment manufactory | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15348321832 |

| Contact: | Klina Han (sales) |

| Last Online: | 19 Jul, 2017 |

Related Products of this Company

-

plastic spoon metallizing plant

US $60000

-

magnetron sputtering machine for

US $50000

-

resistance evaporation coating machine

US $32000

-

PVD evaporation vacuum coating machine

US $32000

-

vacuum metallizing colors for plastic

US $32300

-

Plastic metallizing machine for plastic

US $30000

-

Christmas ornaments metallization

US $35000

-

horizontal vacuum metallizing machine

US $30000

-

multi arc ion plasma vacuum spray

US $60000

-

High Vacuum Coater For Headlight

US $32300