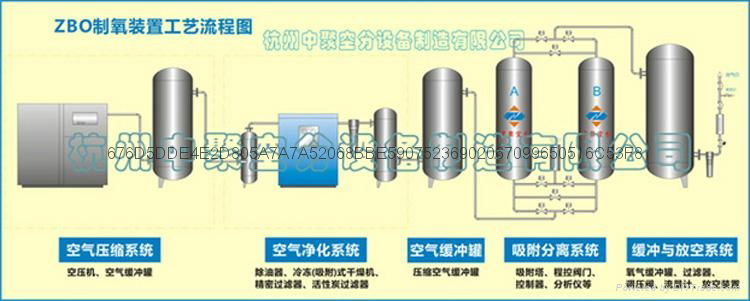

The PSA machine based on zeolite as adsorbent, using pressure adsorption principle, step-down desorption adsorption and release of oxygen from the air, thereby separating the automation equipment of oxygen. The zeolite molecular sieve is a kind of spherical granular adsorbent, which is formed by the special hole processing technology. The surface and the inner surface and the interior is filled with micro pores. Its groove characteristics enable the separation of oxygen and nitrogen. The separation of oxygen and nitrogen by zeolite molecular sieves is based on the small differences in the kinetic diameters of these two gases. Nitrogen molecules have a faster diffusion rate in the micro pores of zeolites and slower diffusion rate of oxygen molecules. Diffusion of water and carbon dioxide in compressed air has little difference between nitrogen and nitrogen. Oxygen molecules are enriched in the end from the adsorption tower. PSA is the choice of adsorption properties of zeolite molecular sieve by using the pressure adsorption, desorption cycle decompression, the compressed air into the adsorption tower to achieve alternating air separation, so as to continuously produce product of high purity oxygen. PSA oxygen machine according to a pressure swing adsorption principle, using high quality zeolite molecular sieve as adsorbent under pressure, oxygen from the air. After purification of dry compressed air, the pressure of adsorption and desorption in vacuum adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in zeolite molecular sieve is much greater than that of oxygen, nitrogen is adsorbed by zeolite molecular sieve, and oxygen is enriched in gas phase. And then the pressure was reduced to normal pressure, the adsorbent was attached to the adsorption of nitrogen and other impurities, to achieve regeneration. General settings in the system of two adsorption towers, tower adsorption oxygen producing, another tower desorption regeneration, through the PLC program controller to control gas valve opening and closing, so that the two towers cycle, in order to achieve continuous production of high quality oxygen. The whole system consists of the following components: compressed air purification module, air storage tank, oxygen nitrogen separation device, oxygen buffer tank.