| Model: | T10 |

|---|---|

| Brand: | QGM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Hydraulic Pressure Machine & Parts |

| Label: | block machine , brick machine , hollow block |

| Price: |

US $85000

/ set

|

| Min. Order: | 1 set |

Product Description

|

Main Technical Specifications |

|

|

Production per Mould: |

10 pcs/mould (Standard Block: 400x200x200mm) |

|

54 pcs/mould (Solid Block: 240x115x53mm) |

|

|

27 pcs/mould (Interlock: 225x112.5x60mm) |

|

|

35 pcs/mould (Holland Brick: 200x100x60-80mm) |

|

|

Cycle Time: |

15 seconds |

|

Production per Shift (8 Working Hours): |

Hollow Block (400x200x200mm): 19200 pcs |

|

Solid Block (240x115x53mm): 103680 pcs |

|

|

Interlock (225x112.5x60mm): 38880 pcs |

|

|

Holland Brick (200x100x60-80mm): 50400 pcs |

|

|

Vibrating Frequency: |

2940 rolls/minute or 50 HZ |

|

Vibrating Force: |

100 KN |

|

Motors Power: |

48 KW |

|

Machine Dimensions: |

7568x2060x2968mm (excluding electrical control box) |

|

Pallet Size: |

1250x850mm |

|

Gross Weight: |

About 15T |

|

Raw Materials: |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes etc. |

|

Applied Products: |

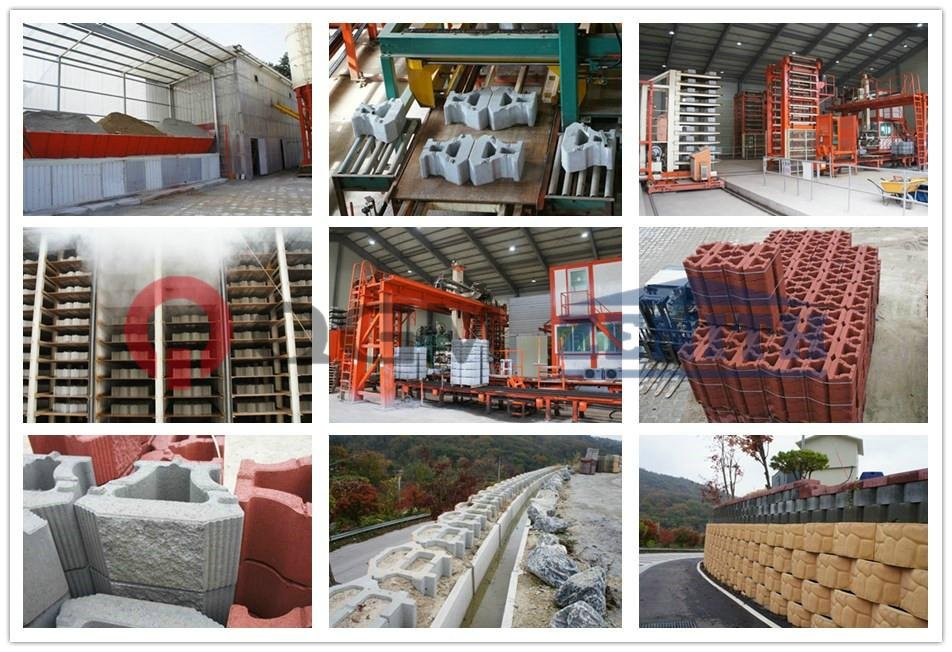

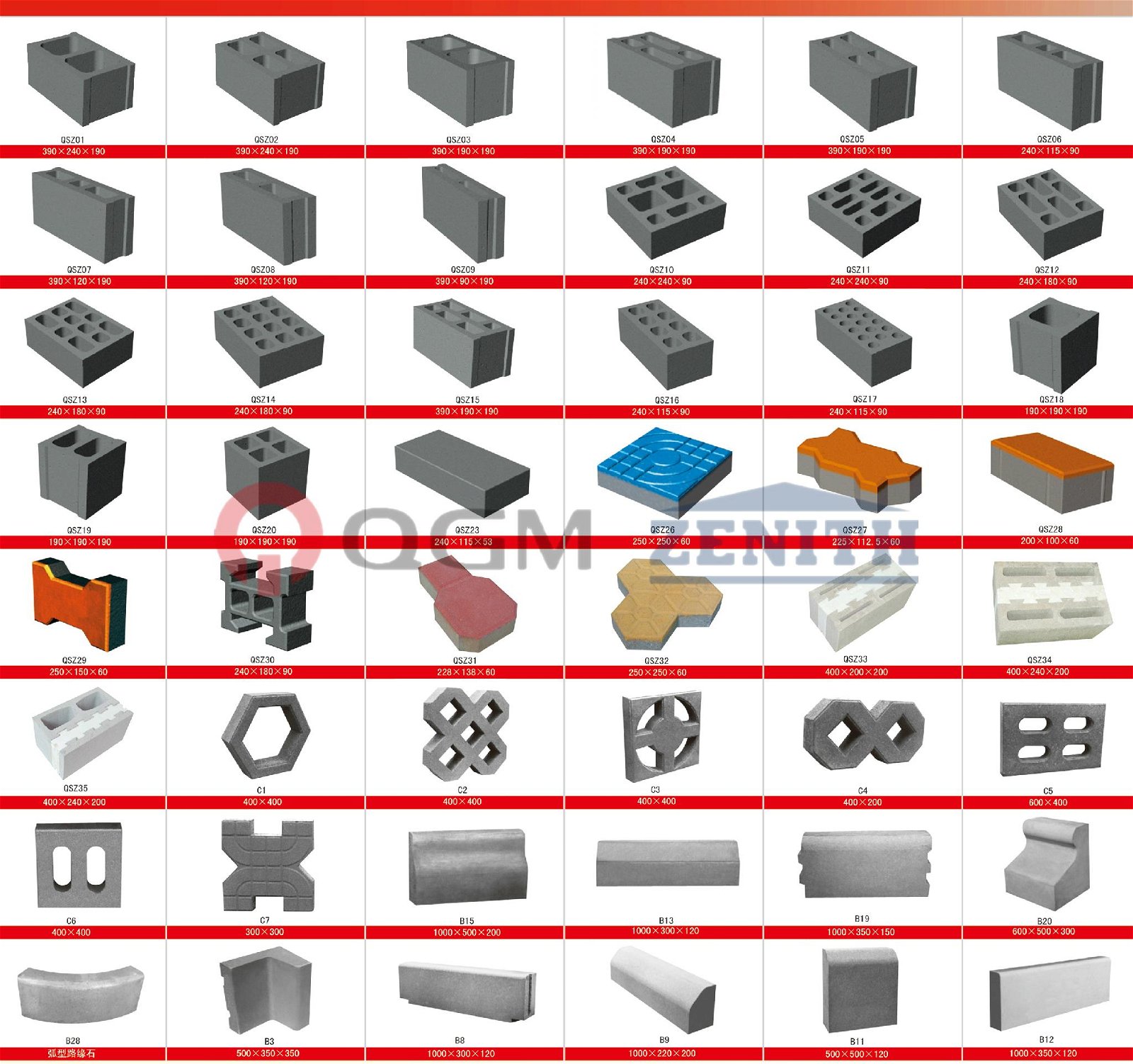

Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, curbstones, grass blocks, slope blocks, interlocking blocks, etc. |

|

Applied Fields: |

Widely used in buildings, road pavers, squares, gardens, landscaping, city constructions, etc. |

BIG FIVE ADVANTAGES OF QGM AUTOMATIC BLOCK MAKING MACHINES

Our machines, with harmonic cooperation between mechanical, electrical and hydraulic machines functions, guarantee a reliable and high output production of concrete products.

1. Use Germany Siemens PLC control system and Siemens Touch Screen, use Schneider and Omron relays and contactors:

A. Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

B. Visualization touch screen, with easy operation.

C. High-quality electrical components from Schneider and Omron.

2. Use Frequency Conversional Control Technology to control the block making:

A. Frequency Conversion Control: guarantee the precise and parallel movement between tamper head and mould; protect the products from transfiguration; increase the production rate by improving the vibrating efficiency.

B. Control the instantaneous start and stop of the motors to protect the motor from over-heating caused by constant working.

C. Power saving: 30%.

3. Use Double High-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure:

A. Buffer the hydraulic cylinder to protect the cylinder from damage caused by inertia.

B. Guarantee production stability.

4. 360° Multi-Shaft Rotating and Compulsory Feeding:

A. Speedy and rotating feeding, with uniform mixing, guarantees the density and intensity of the products.

B. This uniform feeding is applicable for different kinds of raw materials and moulds.

5. Use heat treatment on moulds and main parts of the machines:

A. Heavy duty machine structure and wear resistant moulds.

B. The hardness reaches up to HRC 52-58.

C. Greatly improve the using lifetime of the machine by 50%.

Member Information

| Quangong Machinery Co., Ltd. (QGM) | |

|---|---|

| Country/Region: | Fu Jian - China |

| Business Nature: | Manufacturer |

| Phone: | 18105956873 |

| Contact: | Wendy Guo (Sales Representative) |

| Last Online: | 21 Dec, 2016 |