| Model: | - |

|---|---|

| Brand: | win ceramic |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-metallic Mineral Products |

| Label: | Ceramic Lined Elbow , wear Resistant Steel , High Quality Alumina |

| Price: |

US $289

/ pc

|

| Min. Order: | 1 pc |

Product Description

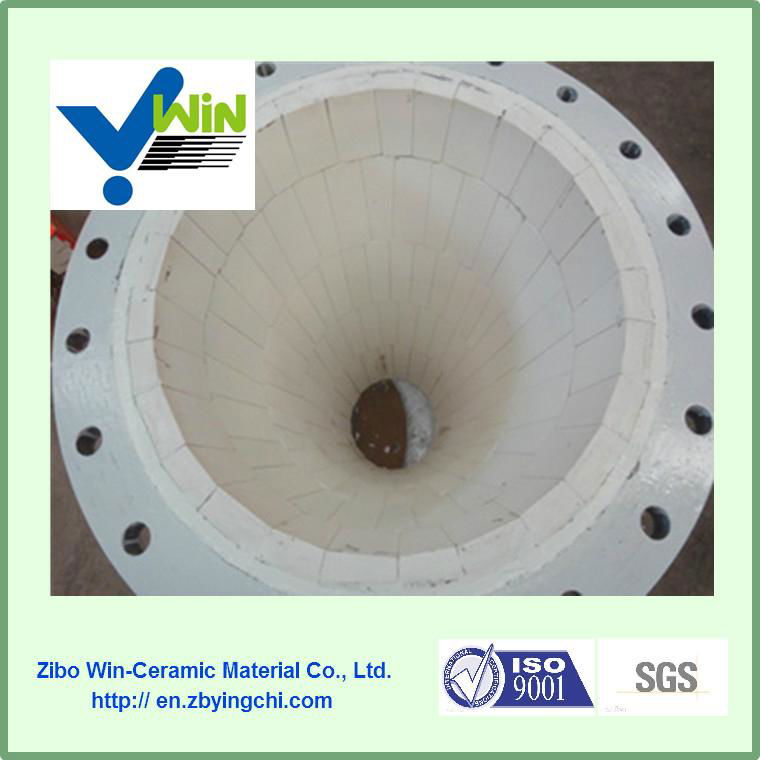

Alumina Ceramic Lined Wear Resistant Bends/elbows,Alumina Ceramic Lined Bends/elbow/tube/pipe

Product Description

The wear resistant pipe is an excellent wear protection pipe used in all industry where need wear resistance. The high alumina ceramics are installed onto the internal surface of the pipe properly by welding, pasting or interlocking system. With the brilliant properties of resistance to wear, corrosion and heat , the pipe is widely used in material handling of coal industry, electric power, metallurgy, mining and chemical industry and it is one ideal wear-resistant pipe.

Regular sizes:

|

Nominal Diameter |

50~800 |

Make detailed specifications based on site conditions. |

|

Thickness of Wear-resistant Liner(mm) |

3~50 |

|

|

Thickness of Steel pipe |

4~8 |

Remark: Other sizes are available upon request.

Key benefits:

(1)Great Hardness: The Mohs hardness is 9 which is only inferior to diamond but far exceeding wear-resistant steel and stainless steel.

(2)Good Abrasion Resistance : The alumina ceramic abrasion resistance is 260 times that of manganese steel and 170 times that of high chromium iron. According to the follow-up survey for the customer, the service life of pipes can be prolonged more than 10 times under the same working condition.

(3)Corrosive Resistance :As an inorganic oxide, high alumina ceramics has extreme stable molecular structure and no electrochemical corrosion, which can resist the corrosion from various solutions such as acid, alkali, salt and organic solvent.

(4) High Self-lubrication :High alumina ceramics has the properties of excellent self-lubrication and non-adhesive. Its roughness is just 1/6 that of steel pipe, causing smaller flow-resistance. Compared to that of steel pipe, its inner diameter could be reduced by 15.4%.

(5)Light Weight : Density of 3.6g/cm3 is only 50% that of steel, which highly decrease the total weight of the pipe

(6)Convenient Connection :Apply flange connection in principle, but we also use quick connector according to the requirements from customers.

Manufacturing

Packaging & Shipping

Company Information

Zibo Win-Ceramic Material Co., Ltd., located in Zibo city, Shandong province, provide excellent abrasion and impact resistance for Mining and Industry applications, focusing on the development of wear-resistant alumina ceramic tile and ceramic tiled lined parts. With more than twenty years experience and 200 high skilled workers ,we produce more than 2000 tons alumina ceramic and related products per month.

Our company overview

Our certificate

Our Customer

Customer Visit

Our Services

FAQ

♣Q: Are you a trading company or factory?

A:We're trading company with factory. We manufacture products by ourselves and we source from other collaborative factories too which guarantees a competitive price and product variety.

♣Q: How do I know your quality?

A: High solution detailed photos and free sample will be able to verify our quality.

♣Q: What is your experience in your products?

A: We have over 20 years experience in high alumina ceramics. We are professional in this area.

♣Q:Can I get a sample first? And how does it charge?

A: Yes, free sample is available with freight collect or prepaid.

♣Q:What if the products broken during transiton?

A:All our products are insured. our after sales will sort our reasons and will sure you'll be properly compensated

♣Q:What's the benefit for long term importers or distributors?

A:For those regular customers, we offer incredible discount, sample free shipping, free sample for custom design, custom packaging and QC as per custom requirements.

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Zibo Win-ceramic Material Co.,Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13475595746 |

| Contact: | Cathy Zheng (sale manager) |

| Last Online: | 02 Dec, 2016 |

Related Products of this Company

-

High quality alumina ceramic tile

US $2450

-

92% 95% Al2O3 Wear Resistant Alumina

US $1.95

-

High Alumina Ceramic Lining Brick For

US $890

-

Win-ceramic alumina ceramic or porcelain

US $1250

-

Customized size activated ball as

US $1

-

Chinese ceramic hexagon mosaic tiles

US $2.3

-

Micro yttria stabilized zirconia beads

US $22.8

-

Inert ceramic ball high alumina pellet

US $1688

-

Inert alumina ceramics ball support

US $1

-

Win-ceramic activated alumina beads as

US $1235