| Model: | QS10+10 |

|---|---|

| Brand: | QS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-metallic Mineral Products |

| Label: | alumina ceramic , ceramic liner brick , 92% al2o3 brick |

| Price: |

US $2

/ pc

|

| Min. Order: | 1 pc |

Product Description

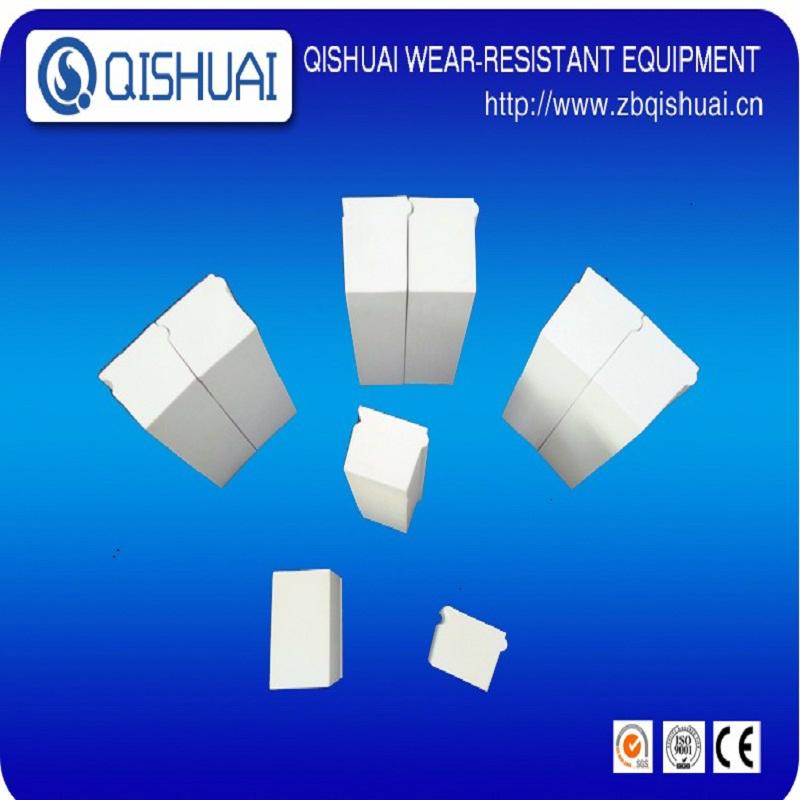

92% Al2o3 best quality alumina ceramic liner bricks

High Density Alumina Ceramic Tile offers excellent mechanical properties, superior wear resistance and desirable corrosion performance.

Advanced processing techniques enable manufacturing of alumina in a variety of geometries from simple to complex shapes and sizes allowing Qishuai to customise ceramic lining systems to suit Client specific requirements.

Quality alumina tile combined with Qishuai’s fully compliant and preferred installation methodology, high density alumina ceramic overcomes temperature limitations, impact and abrasion concerns in various environments. High Density Alumina Ceramic Tiles can be epoxy bonded or fitted with weld ferrules to chutes; buckets; plates; pipes; bends; and cones.

Alumina Ceramics Technical Parameter

|

Alumina Content |

|

80-85% |

90-96% |

> 99.5% |

99% |

|

General Application |

|

Lower Cost Electrical & Mechanical |

High Strength, Wear Resistant, Electronic, Insulating, Mechanical, Structural & Metalizing |

Extremely High Purity, Temperature & Strength; Excellent Corrosion & Wear Resistance |

Porous, Easily Degassed & Machinable |

|

Porosity |

% |

0-.05 |

0-.05 |

0-.05 |

Variable |

|

Density |

gm/cm3 |

3.45-3.50 |

3.55-3.75 |

3.75-3.95 |

2.4 |

|

Flexural Strength |

kpsi |

35.0-40.0 |

40.0-50.0 |

50.0-55.0 |

- |

|

Comprehensive Strength |

kpsi |

260.0 |

> 300.0 |

> 300.0 |

- |

|

Tensile Strength |

kpsi |

15.0-20.0 |

20.0-28.0 |

20.0-28.0 |

- |

|

Linear Coefficient of Thermal Expansion |

(cm/cm/°C) 25-300°C 25-700°C |

5.9X10-6 6.5X10-6 |

6.3X10-6 7.0X10-6 |

6.5X10-6 7.5X10-6 |

6.5X10-67.5X10-6 |

|

Dielecctric Constant at 25°C |

1 MH 10 MH |

8.5-8.9 8.4-8.8 |

9.2-9.8 9.0-9.6 |

9.5-9.9 9.3-9.7 |

- |

|

Dielectric Strength |

Volt/mil |

200 |

225 |

225 |

- |

|

Te Value |

°F °C |

1472 800 |

> 1832 > 1000 |

> 1832 > 1000 |

> 1832 > 1000 |

|

Thermal Conductivity at 25°C |

cal/sec/cm2/cm/°C |

.03-.04 |

.04-.06 |

.07-.08 |

- |

|

Thermal Shock |

|

Good |

Good |

Good |

Good |

|

Safe Use Temperature |

°F °C |

2550 1400 |

3000-3100 1650-1700 |

3275 1800 |

3275 1800 |

Shandong Qishuai wear protection equipment Co. offers a range of abrasion and wear resistant products and services required for metallurgy, coal mine and electrical, etc industry.

Qishuai strives to partner it's customers in their success. Qishuai understands that it is not enough to offer only products but to understand the need of its customers and provide solutions and value added consultancy services which are tailored to suit specific customer requirements. This has translated into the adoption of a “TOTAL SOLUTION” approach by Qishuai for catering to its customers by leveraging its in-depth knowledge of metallurgy, coal mine and electrical processes.

Today Qishuai is a recognized world leader in providing customised solutions which are critical components in driving efficiency and ensuring lower cost per tonne of operation.

Why choose ZIBO QISHUAI?

·Professional manufacturer.

· ISO9001 compliant to guarantee quality.

·Timely after sales service.

·Customized available

How to get wanted offer?

·We can offer as your designed drawings and technology requirements.

·We can make solutions based on your application parameter types of abrasion, system and equipment design operating temperature and materials.

Member Information

| Shandong Qishuai Wear-resistant Equipment Co.,Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15169306766 |

| Contact: | gloria yang (saler) |

| Last Online: | 14 Dec, 2016 |

Related Products of this Company

-

Alumina ceramic liner brick

US $2

-

China manufacturer 95% ceramic liner

US $2

-

High quality ceramic linings brick for

US $2

-

Bimetallic alloy welding wear resistant

US $150

-

92% Alumina ceramic wear resistant liner

US $2

-

Competitive price alumina ceramic liner

US $5

-

95% High hardness alumina ceramic wear

US $3

-

Alumina ceramic wear resistant liner

US $3

-

White high hardness alumina ceramic

US $3

-

No Image

Arasion resistant al2o3 92% ceramic

US $3