| Model: | SGECS-80 |

|---|---|

| Brand: | JSYY/EJET |

| Origin: | - |

| Category: | Industrial Supplies / Environment Protection Facilities / Other Environment Protection Facilities |

| Label: | Alumium Separator , aluminum Auto-sorter , Cans Classifier |

| Price: |

US $22800

/ pc

|

| Min. Order: | 1 pc |

Product Description

Eddy current magnetism separator automatically pick up aluminum and steel cans from all waste colleted recycling station

The Eddy Current Separator (ECS) is an advanced metal sorting unit that is capable of separating non-ferrous metals such as aluminium and copper from dry recyclables.

Those particular eddy current beveragen cans sorting machine can produce higher purity and increased yield of better separation of aluminum cans from PET plastic beverage containers.In nowdays it is bacame the most economical beverage bottle sorting and recycling equipment.

Standard Features and Benefits for magnetism alumium/copper recovery machine

1. Designed with top grade NdFeB or permanent rare earth magnet material , having high-strength magnetic field and long life

2.Non-ferrous metal recovery in refuse streams and ash streams in Waste-to-Energy facilities,can up 98% recovery rate of aluminum cans from commingled recyclables

3.Import main parts:Nord Gear Motor,NSK Bearing,Seigling Belt,Schneider Electric

4.R ed heavy-duty construction effectivily reduce belt long-term wear.

Working principle

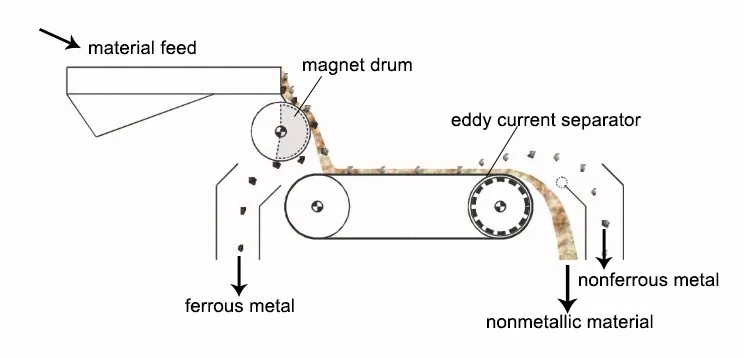

When a piece of non-ferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed. This forms eddy currents in the aluminum which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the nonmetallics, allowing the two material streams to be separated.

Important: When looking at an Eddy current separator, the waste travelling over the magnetic must be in a thin layer to allow the magnetic perform to its best, in case processed metal waste is mixed with ferrous metal. The Ideal format for any metal separation is first magnetic ferrous discharge, onto a vibration conveyor to spread out and further separate the remaining metals to allow the Eddy current magnetic to work at its optimal efficiency.

Also Particle size can matter, since the eddy current depends on surface area. Pieces of scrap that are a half-inch in size or larger work best.

Specification

|

Model |

Belt Width |

Motor Power |

Dimension (mm) |

Weight |

||

|

mm |

Kw |

Length |

Width |

High |

Kg |

|

|

ECS-40 |

450 |

3.0/0.75 |

2080 |

1357 |

1100 |

1100 |

|

ECS-65 |

650 |

4.0/1.5 |

3300 |

1500 |

1200 |

1200 |

|

ECS-80 |

800 |

5.5/1.5 |

3300 |

1700 |

1200 |

1400 |

|

ECS-100 |

1000 |

5.5/1.5 |

3300 |

1900 |

1200 |

1600 |

|

ECS-120 |

1200 |

5.5/2.2 |

3300 |

2000 |

1200 |

1800 |

|

ECS-140 |

1400 |

7.5/2.2 |

3620 |

2130 |

1587 |

2100 |

|

ECS-150 |

1500 |

7.5/2.2 |

3420 |

2240 |

1530 |

2200 |

|

ECS-180 |

1800 |

7.5/2.2 |

3300 |

2700 |

1200 |

2800

|

Application for alumium cans eddy current recovery machine

separation alumium and steel cans ,conductors recovery from rubber,glass,wood waste and other non-ferrous materials.

Mainly application for eddy current non-magnetic metal separator

Bulky-waste crush lines

Aluminum separators enhance the efficiency of separation and recovary of aluminum from crushed city waste.

Recovery of conductors from glass cullet

Aluminum separators streamline the recovery and separation of valuable metals contained in glass cullet.

Processing of aluminum molding sand

Aluminum separators wield will be useful in the recovery of aluminum scrap in aluminum-shell-sand recycling lines.

Classification of aluminum and steel cans

Aluminum separators automatically pick up aluminum and steel cans from all waste collected from the recycling stations and service areas along highways.

Recovery of aluminum from PET bottles

Aluminum separators allow for efficient separation and recovery of aluminum from crushed PET bottles.

Separation of nails used in pachinko game machines.

Recovery other conductors

Packaging & Shipping

1.Packing:Export packing for eddy current separation equipment

2.Shipping time: 30 days after receive the deposit

we can design and manufacture complete eddy current conveyor systems or simply furnish eddy current drums or any other piece of magnetic separation equipment to meet your requirements.such as:

1.eddy current nonferrous metal magnetic separator

2.permanent and electric magnetic separator

3.wet and dry type magnetic separator

4.Permanent magnet and electromagnetic lifting equipment

5.magnetic drum

6.chute magnetic separator

7.magnetic sweeper

8.magnetic cartridges(rods or tubes)

9.Belt conveyor

10.screening

11.vibrating feeder

and air classifier can also be provided

Most suitable machine would be recomended to you according to your informations.

Any requirement Please Contact Miss Jasmine Song :

Email: jsyy@sino-magnets .com.cn

Mobile: 86 15242300557

WhatsApp: 86 15242300557

Skype: luckjasmine86

Wechat: 86 15242300557

QQ: 377375411

| Price Terms: | FOB/CNF/CIF Dalian |

|---|---|

| Payment Terms: | TT/LC/Western Union |

| Packing: | alumiunm/steel cans recycling machine exporting package |

| Lead Time: | shipped within 30workindays after get the deposit |

Member Information

| Fushun Ejet Magnetic Equipment Co.,Ltd | |

|---|---|

| Country/Region: | Liao Ning - China |

| Business Nature: | Manufacturer |

| Phone: | 13841385864 |

| Contact: | Johnson (Sales Manager) |

| Last Online: | 14 Dec, 2024 |

Related Products of this Company

-

Laboratory Eddy Current Separator for

-

High Quality CE Certified Plastic

US $18900

-

Eddy Current Separator electronic

-

ECS200P Scrap Aluminum Separation

US $23000

-

ECS200P Scrap Aluminum Separation

US $23000

-

Scrap zorba metal sorting system

US $20000

-

Precision Sensor Sorter Machine Separate

US $220000

-

Eddy Current Separator Islamic Republic

US $27500

-

Eccentric pole system eddy current

US $20000

-

Eddy current separator aluminum copper

US $9500