| Model: | - |

|---|---|

| Brand: | YUHAO |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | mosi2heating element , molybdenum disilicid , mosi2 heater |

| Price: |

US $10

/ pc

|

| Min. Order: | 10 pc |

Product Description

Molybdenum disilicide(MoSi2) heating element is one resistance heating component made from MoSi2 or as the basic material. When it’s heated to high temperature under the oxidizing atmosphere, one dense MoSi2 film will be formed on its surface to protect the element against oxidizing further. Therefore, the element has unique anti-oxidation property under high temperature atmosphere. The highest temperature can reach 1800°C, the applicable temperature is between 500-1700°C.

Applications: It can be used as heating elements of industrial high-temperature furnace, like ceramics, magnetic materials, glasses, metallurgy, refractory, etc.

Physical and Chemcial Properties

1.Physical property

| Volume Density | Bending Strength | Vickers Hardness | Porosity | Water absorption | Heating Elongation Rate |

| 5.5g/cm3 | 15-25kg/cm2 | (HV)570kg/mm2 | 7.4% | 1.2% | 4% |

2. Chemistry Property

Mosi2 heating element is used in the high temperature under oxidizing atmosphere. It will form the SiO2 film which can keep the element from being melted. When the temperature of element is more than 1700 °C, the SiO2 protecting film is formed again when the element continues to be used. The Mosi2 heating element must not be used in the temperature between 400°C and 700°C, otherwise the element will be creamed under the strong oxidizing function in the low temperature.

Advice of Installation

1. MoSi2 heating element is very brittle under room temperature and plastic under high temperature. Therefore, it’s the best way for installation of U type element to hang it vertically. Such way is to avoid putting the mechanical stress directly to the Hot Zone of the element, otherwise, the element will be broken easily. If it needs hang horizontally, please choose a support of high temperature refractory.

2. Please put the taper part of the element bottom into the furnace chamber to avoid local overheating.

3. The lead wire should be a little longer than the linear distance between the element and the bus to avoid putting the stress to the element.

4. Please don’t tighten the screw of clamps too much at one time. It can be tightened when the element heats up to high temperature because of the element’s plasticity.

5. The temperature of the clip should be less than 200°C, the contact voltage between the clip and the element should be less than 0.1V.

6. The distance between the lower end of the clip and the upper surface of the through brick should be more than 50mm, to avoid the radiation heat conducting to the clip.

7. To avoid damage, 170A couldn’t be used for long term for the element of Ø6/12mm; 300A couldn’t be used for long time used for the element of Ø9/18mm.

Replacement of Element

If it is found that one element is damaged during operation, you should determine where it is and prepare a made up one simultaneously. Then loose the screw which links the lead wire of the damaged element and the bus, clear out the ceramic cotton and pull out the through brick. Afterward, insert the new element from the furnace top, link the lead wire, block the gap with ceramic cotton and start raising temperature.

When you enquiry, please tell us the following data:

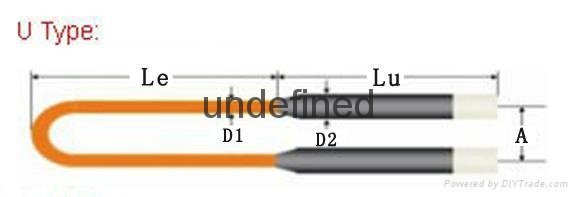

DI: Diameter of Hot Zone(mm)

D2: Diameter of Cold Zone(mm)

Le: Length of Hot Zone(mm)

Lu: Length of Cold Zone(mm)

A: Shank Spacing(mm)

Member Information

| Dengfeng city Yuhao high-temperature component CO.,LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15937181552 |

| Contact: | Serena Lee (Sales manager) |

| Last Online: | 17 Jan, 2017 |