| Model: | - |

|---|---|

| Brand: | xhh |

| Origin: | Made In China |

| Category: | Construction & Decoration / Building Steel & Structure |

| Label: | type of roofing shee , price of roofing she , used metal roofing |

| Price: |

US $1250

/ TON

|

| Min. Order: | 1 TON |

Product Description

Color coated aluminum sheet coil for roofing and wall cladding system

1. Specifications of color coated coil

| (1). product presentation

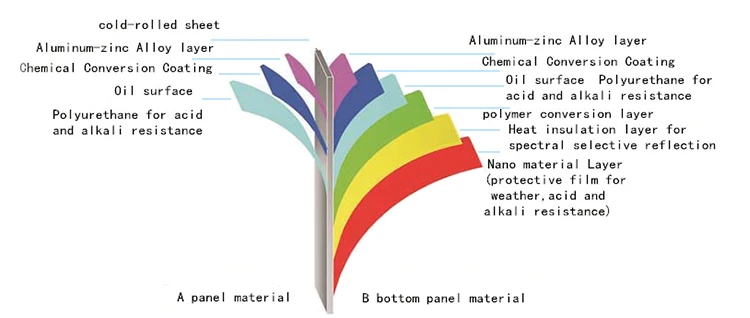

Weather resistance and heat insulation plate is also called acid and alkali heat insulation nano plate, Heat Insulation PPGI Aluminum Panel .It is a kind of composite metal plate , as shown in picture ,the top and bottom surface are Galvalume Layer, Chemical Conversion Coating and Oil surface acid-base polyurethane.On top surface also including Polymer Conversion Layer ,Spectral Selective Reflection And Heat Insulation Layer and Nano Material Layer(weather resistance, acid and alkali resistant protective film).This high performance-price ratio building roofing, outer wall material is great satisfy the composite demand of modern construction industry and has been widely used.

(2). product property 1).Good Insulation Effective : Highly heat reflectivity makes the surface of roofing can’t absorb heart,even in the hot Summer, the surface of roofing is not hot,and will lower 8-10 degree indoor . 2).Strong Acid and Alkali Resistance and Corrosion Resistance : can save a lot of manpower and material cost for highly polluting enterprises . 3).Strong Weathering : -20℃ to 100℃ below are applicable . 4).High Self-cleaning : with antistatic effective and smooth surface,don’t need often clean . 5).Good Fire Safety : insulation combustion,insulation,has fire resistance . 6).Strong Environmental Protection : with convex and concave surface,it can not shine,no light . 7).Any Profiles : can provide unlimited creative space for the architect , to build beautiful and unique construction,create the perfect visual effect . 8). Safe and Reliable : all parts adopt rigid connection,can be powerful typhoon attack resistance . 9).Light Weight : requirements of weight for steel structure is reduced,less construction difficulty. 10).Easy Installation : Easy to install,it will be shorter building time and save project cost . 11).Long Life : surface quality is reliable,inner quality is consistent .

(3). performance test We had done many test in order to check its performance: Experiment 1:Heat Insulation PPGI Aluminum Panel had been tested in America: insolated 2 hours under high temperature 120℃, then immediately under the low temperature -20℃ for 2 hours, repeatedly 20 times like that, no found the sign of peeling off. Experiment 2: cooked in the boiling water for 2 hours, no found the sign of peeling off. Experiment 3:Insulation test. |

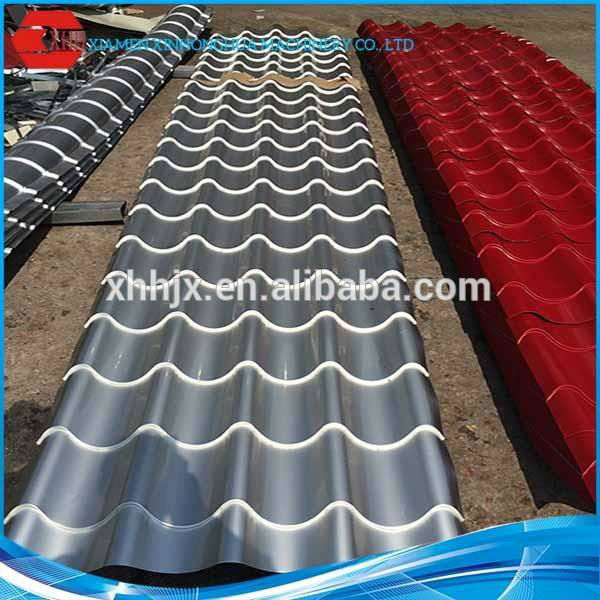

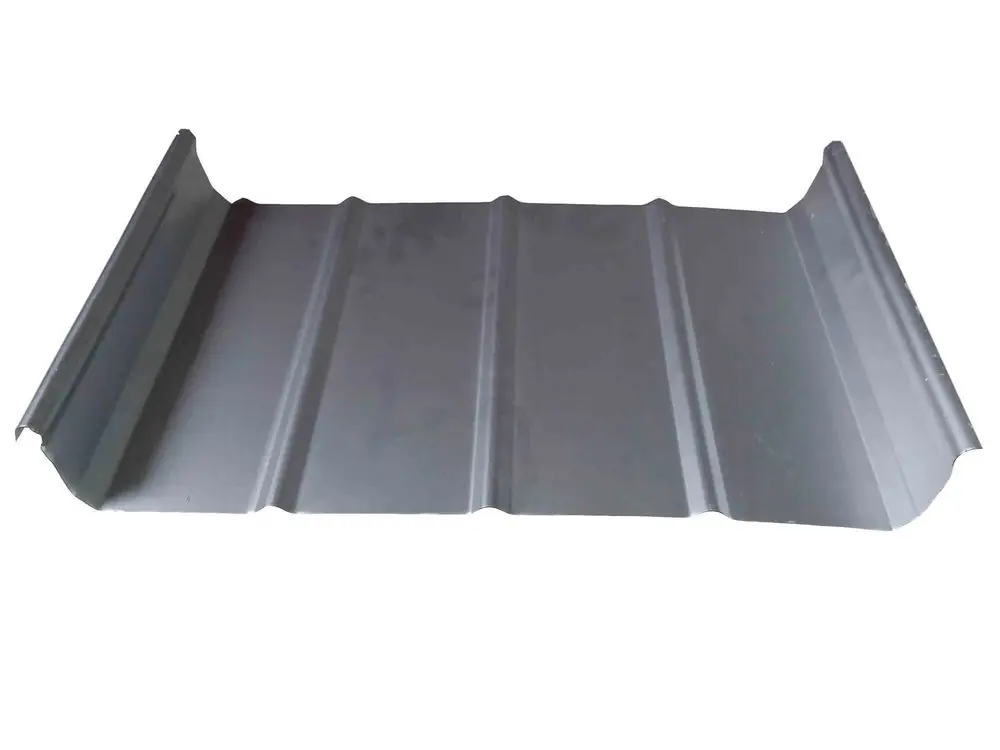

2. Pictures of color coated coil

3. Certifications of Product

4. Applications of Product

Heat Insulation PPGI Aluminum Panels are applicable for the roofings and walls of industrial plants,

civil buildings, grain storage facilities, large wholesale markets,large farmers markets, etc.

With good Anti-acid and corrosion protective, this roofing panel is very applicable for the Chemical Plants,

Electroplating Factory, Ceramics Factory,Livestock, Foundries,Paper Mills and other heavy corrosionindustrial buildings, can large extent raise the service life of the building.

To ensure the quality of product, our company strictly enforce relevant standard of “JG/T402-2013

[Heat Reflection Metal Roofing]GB/T23443-2009[Architectural Aluminum Veneer]GB/T12755-2008

[Building Pressure Steel]” as the basis of production and acceptance of delivery.

Common Size: 840, 850, 900 Common Thickness:0.426-0.476-0.526mm.

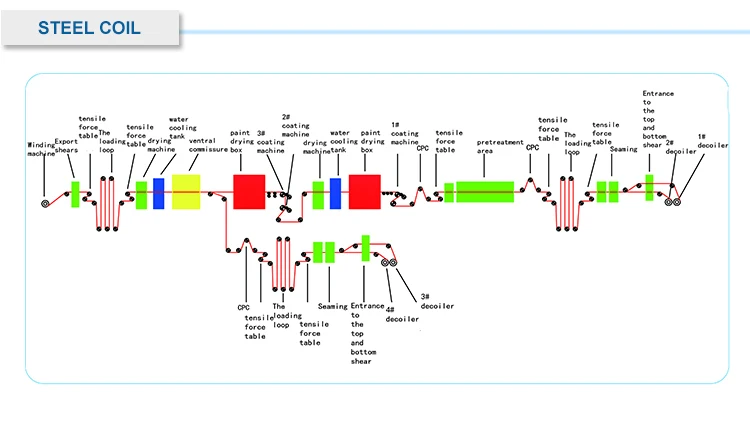

5. Production Line of Product

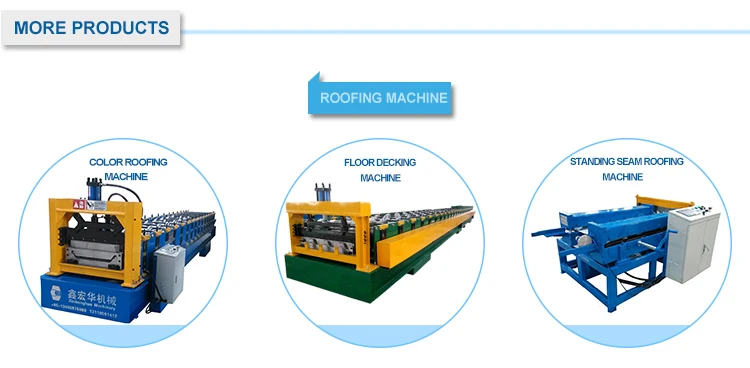

6. More products for you to choose

color roofing machine Floor decking machine Standing seam roofing machine

1.Our Company View

|

Xiamen XinHongHua Machinery Co., LTD.is specialized in design and manufacture roll forming machines for 15 years. With developing technical and various experience, our main machines are:Al- Mg- Mn Straight & Tapered Standing Seam Roofing Forming Machine, Fully Automatic Curving Machine, Fully Automatic Adjustable C Purline forming machine, Automatic Interchange C, Z Purline Machine, Flattening Slitting Cutting Machines,Colored Steel Roofing Panel Forming Machine,Tile Roofing Machine, Floor Decking Machine and Highway Rail Forming Machines, etc.

|

2. Certifications of Our Company

3. Exhibitions and Customers

| steel plate |

Member Information

| Xiamen Xinhonghua Machinery Co., Ltd. | |

|---|---|

| Country/Region: | Fu Jian - China |

| Business Nature: | Manufacturer |

| Phone: | 18960566539 |

| Contact: | Luke LU (Trade Specialist) |

| Last Online: | 20 Feb, 2017 |

Related Products of this Company

-

C89 Light Steel Frame CAD Roll Forming

US $125000

-

Light Steel Structure Villa Forming

US $125000

-

Color corrugated galvanized steel plate

US $1200

-

Light Steel Structure Housings in India

US $125000

-

Long service life Heat Insulation Color

US $1200

-

Portable Dwelling Forming Machine

US $124000

-

Prefabricated Housing Manufacturing

US $124000

-

Energy conservation Steel panel coil

US $1250

-

Tight Weather Resistance Superior

US $1250

-

Lightweight Steel Construction Forming

US $126000