| Model: | RP 1003-2018 |

|---|---|

| Brand: | Metso |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | high press grinding , high press grinding , CITIC IC roller sle |

| Price: |

US $10000

/ t

|

| Min. Order: | 1 t |

Product Description

Product Description

CITIC IC wear parts of press roller & roller sleeve &High Pressure Grinding

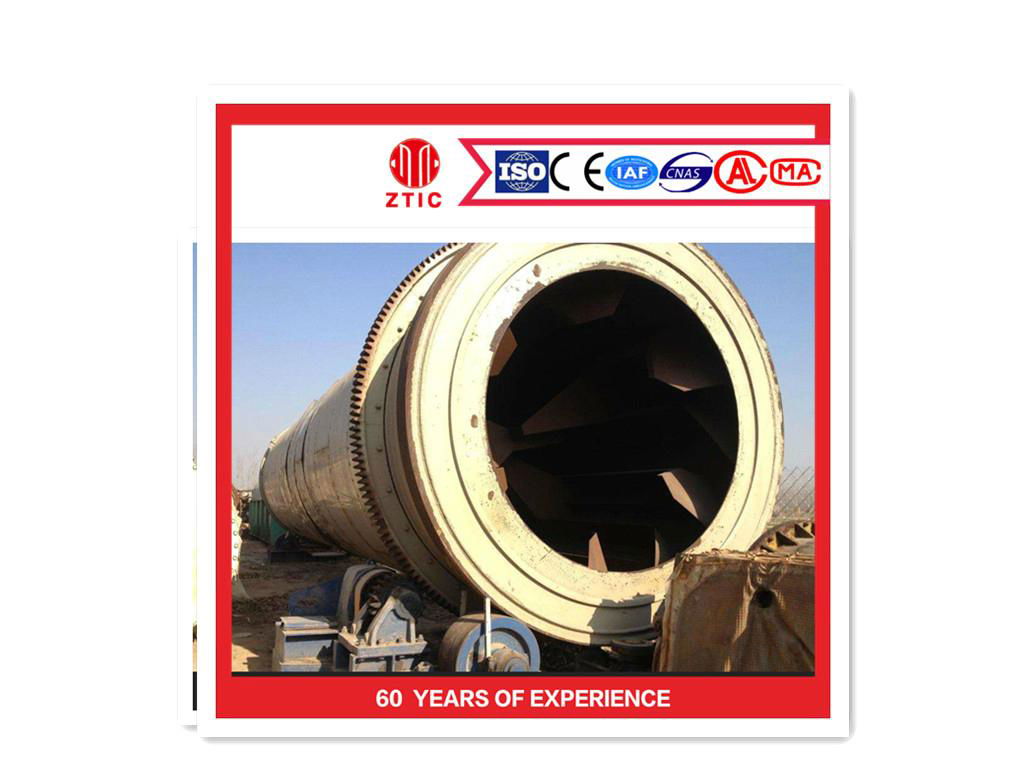

CITIC IC has a full range of Cement Roller Pres -High Pressure Grinding Rolls (HPGR) with an operating base of more than 165 units ranging from HPGR120-50 to HPGR240-180 Cement Roller Pres . Our fully equipped laboratory has a HPGR50-20 Cement Roller Pres to undertake any necessary test work.

CITIC IC wear parts of press roller & roller sleeve &High Pressure Grinding

Cement Roller Press-HPGR:CITIC has a full range of High Pressure Grinding Rolls (HPGR) with an operating base of more than 165 units ranging from HPGR 100-30 to HPGR210-180 Cement Roller Press.

Mine Roller Press:GM series Mine Roller Press from GM 52-20 to GM 200-180,Our fully equipped laboratory has a HPGR50-20 to undertake any necessary test work.

High Pressure Grinding( Roller Presses )

With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame. A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings. The oil is both, lubricant and cooling agent. Alternatively, grease lubrication is possible. Power transmission from the electric motors is effected via cardan shaft, fluid or safe set coupling and clamping disc fitted gear boxes, usually of planetary design. Depending on the application, the rollers are either one piece solid construction or shaft and tire design with suitable wear protection for almost all applications in the cement and minerals industry.

High Pressure Grinding Rolls (HPGR)

CITIC HIC designs and manufactures a range of HPGRs to suit the cement and mineral processing industries. Our HPGR designs range from 120-50 (2 x 355kW) to 240 -180 (2 x 3150kW).

Standard features include:

Constant setting and pressure control

Autogenous wear protection of rolls ensuring improved wear life

Structurally sound welded frame verified using FEA complying to strictest design codes

Dual planetary reducer drive system

Four cylindrical roller bearings design

PLC control system complete with operator panel

‘HPGR Enhancement Package’ which includes the complete HPGR control system, temperature and vibration monitoring and other options to increase equipment availability

Product advantage:

-

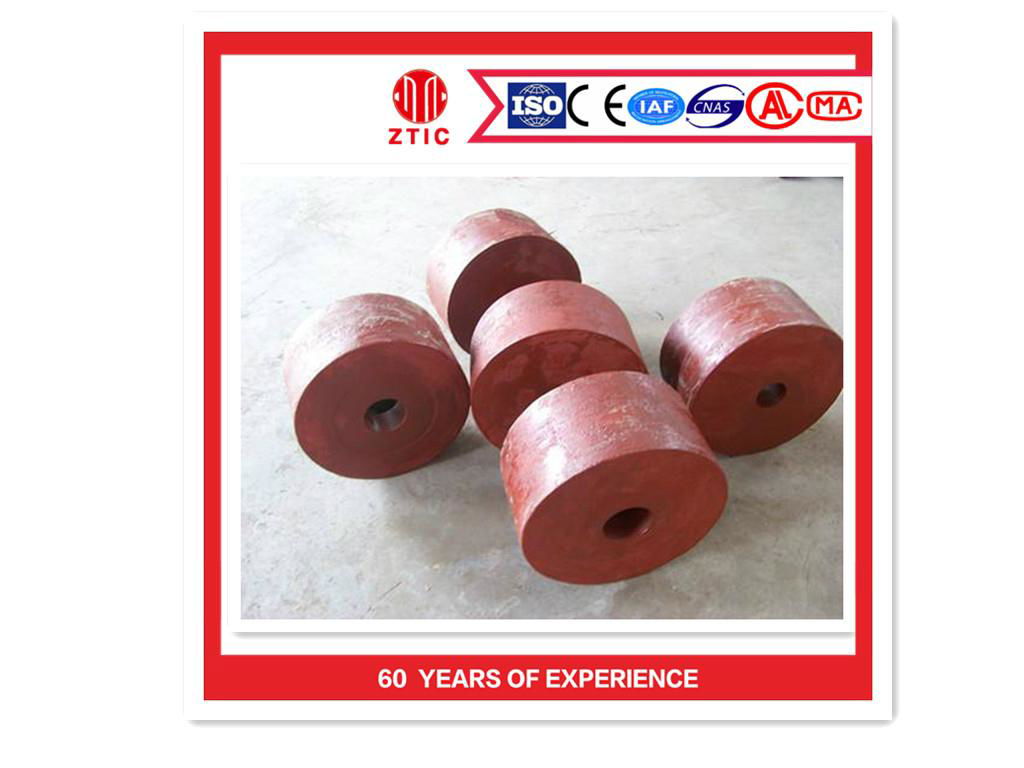

1. The press roller surface adopts hard alloy stud setting-in structure to increase the life time of the roller sleeve

Applicable scope

2. Universal coupling-planetary retarder-press roller to consist of shaft flexible drive system

3. Compound structure of non-contact sealing and contact sealing are adopted at the side of the press roller

4. Unique ellipse structure is used for the feeding pipe to make the feeding process smooth

5. Oil spray lubrication system is used for the lubrication of the main bearing

6. The main bearing adopts inner passage fully-sealing structure for cooling

7. The hard alloy welding press roller surface or setting-in surface are available depending on the user’s need.1. Applicable for the mineral processing industry; it can be installed before the ball mill as pre-milling equipment or consist of mixing grinding system with ball mill.

2. Applicable for oxide pellet industry instead of the common used damp mill.

3. Applicable for building material and fire-proof material industry; successful application for the grinding of clinker, limestone and bauxite. -

Always up to expectations.

The CITICIC Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons. CITIC Roller Presses offer a reliable solution for every application for grinding cement, slag, raw material or for special applications, such as preparation of ore.

A driving force: reasonably stressed.

The drive power is transferred to the grinding rollers via multi-stage planetary gearboxes with first stage spur gears. The gearboxes are mounted on the drive end of the roller shaft using a hydraulic shrink coupling.. A V-belt drive can be used for drives of up to approx. 400kW per motor. Drives above 400kW are equipped with fluid or safe set coupling and cardan shaft.

A framework you'll work better with.

The machine frame has identical upper and lower tiebars. Rubber pads are placed between the roller bearing blocks and the frame ends. The rubber pads act as an articulated joint and have a vibration damping effect. The RPS-type as a special type reduces maintenance time during roller changes. The doors in the roll cover permit rapid and wide access to the rollers for inspection and maintenance.

Roller Presses: roller support

A question of the right bearings.

Roller Press rolls and bearings.

In CITTIC Roller Presses, the rollers are supported in radial, multi-row cylindrical roller bearings. This ensures an even load distribution on the roller bearing, substantially increasing the life of the bearing.

Additional long life design features of CITIC Roller Presses include:

- Generously sized bearing load factor

- Continuous feeding of filtered lubrication oil

- Bearings cooled by the lubrication oil for low bearing temperature

- Bearing sealing with fixed radial shaft sealings arranged back to back

- Additional permanently greased labyrinth with V- ring and separate dust

- labyrinth on the inner side of the bearings.

Oil lubricated roller bearings are standard with all CITIC Roller Presses. All contact points on the cylindrical roller bearing are supplied evenly with lubrication. Operating cost can be further reduced by checking the state of lubricant regularly (alternative grease lubrication).

Roller Presses: rollers, surfaces

Reduced wear by autogenous wear protection.

Grinding Rolls

CITICIC Roller Presses offer rollers with appropriate wear protection for almost all applications in the cement and minerals industry. The two-part roller consisting of shaft and tire allows for economical surface replacement, single part rollers are used for high temperature grinding:

- Multi-layer welding enables long running times without stoppages.

- The complete hard face welded surface is used for feed material of normal wear characteristic. Surface repair can be carried out quickly.

- The surface with hard-alloy studs is used for extremely abrasive materials.

HPGR|Roller Press Technical parameters:

Model Rolle DIA

mmRoll width

(mm)

Main motor

(mm)

Feed Size

mm

Output Size

mm

Production capacity t/h

Weighet/t

Size mm

L

W

H

RP1003

Φ1000

300

160*2

25/40

<2mm

65%

<0.08mm

25%

50-70

33

3835

4510

1885

RP1004

400

200*2

25/40

65-90

36

4080

4600

1920

RP1006

630

315×2

25/40

105-145

55

4526

5280

2200

RP1204

Φ1200

450

220×2

30/50

95-130

62

5500

4470

2340

RP1205

500

250×2

30/50

140-165

64

5550

4620

2390

RP1208

800

455×2

30/50

180-230

90

5608

5500

2460

RP1406

Φ1400

650

455×2

35/60

225-290

104

7205

5440

2610

RP1408

800

500×2

35/60

283-362

125

7400

5780

2610

RP1410

1000

630×2

35/60

420-460

135

6400

8990

3000

RP1509

Φ1500

900

710×2

35/60

340-460

163

6610

8860

3490

RP1614

Φ1600

1400

1000×2

35/60

650-750

190

7000

9320

3980

RP1714

Φ1700

1400

1250×2

40/70

710-830

240

7230

9420

4100

RP1816

Φ1800

1600

1600×2

45/80

800-1000

278

8000

11100

4550

RP2018 Φ2000 1800 2000x2 1250-1450

Member Information

| CITIC Heavy Machinery Co., Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18637916126 |

| Contact: | NEO (SEO) |

| Last Online: | 29 Aug, 2017 |