| Model: | N250 |

|---|---|

| Brand: | JAGUAR |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | mini wave soldering , wave soldering , dip soldering |

| Price: |

US $9000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Good Performance DIP Production Line Component wave solder machine

Product Description

Specification:

|

Model No. |

JAGUAR N250 |

|

Number of heating zones |

2 |

|

Length of heating zones |

600mm |

|

Body size |

1800(L)*1200(W)*1600(H) |

|

Outside dimension |

2600(L)*1200(W)*1600(H) |

|

Weight |

700KG |

|

Total/running power |

11KW/4-6KW |

|

Air supply |

0.5MPa |

|

Preheating method |

Hot air |

|

Preheating power |

220V 5KW |

|

Control method |

Press key +PLC (Option: touch screen, PC) |

|

Range of temp. control |

Room temperature---300℃ |

|

Preheating time |

About 10-15mins for setting 150℃ |

|

Solder type |

Lead-free / Sn-Pb |

|

Solder pot capacity |

220KG |

|

Solder pot temperature |

300℃ |

|

Solder power |

380V 6KW |

|

Solder temp. control method |

PID&SSR |

|

Wave crest drive power |

500W 220V |

|

Warm-up time of solder |

About 120mins for setting 250℃ |

|

PCB width |

50-250mm |

|

Convey speed |

0-1800mm/min |

|

Convey direction |

L→R (R→L optional) |

|

Convey angle |

4—7 º |

|

Flux pressure |

3-5 bar |

|

Flux capacity |

3.2L |

Introduction:

1. Automatic conveying power system and auto synchronous board feeding functions.

2.Tin stove peak uses frequency conversing speed adjustment which can independently control the wave height.

3.Flux sprays system using scanning spray nozzle, Japanese nozzles and rodless pneumatic cylinders and PLC control, accurate and reliable.

4.PLC is used to control the machine, to ensure the reliability and stability of the system.

5.With Remote Infrared Ceramic heating pipe preheating device, heat radiation directly to the circuit board bottom, fast heating and stimulate the full activity of flux.

6.Special alloy transportation chain claws, non-stick tin and ensures the

7.quality of welding PCB board.

8.Tin stove adopts imported high frequency conversion motor independent control, stable performance.

9.Lead-free solder furnace with independent design, environment protection and safety, easy to clean.

10.Preheating system uses three independent temperature control so that ensure the excellent heat preservation, temperature uniformity, temperature difference no more than ±2ºC.

11.Time can be controlled, we can preset switch functions, tin stove can heat within 90 minutes.

12.automatic claw cleaning function ensure the cleanliness of claws.

13.Reasonable design and sensitive fault security alarm system ensure the stable performance and operators’ safety.

Packaging & Shipping

Our Services

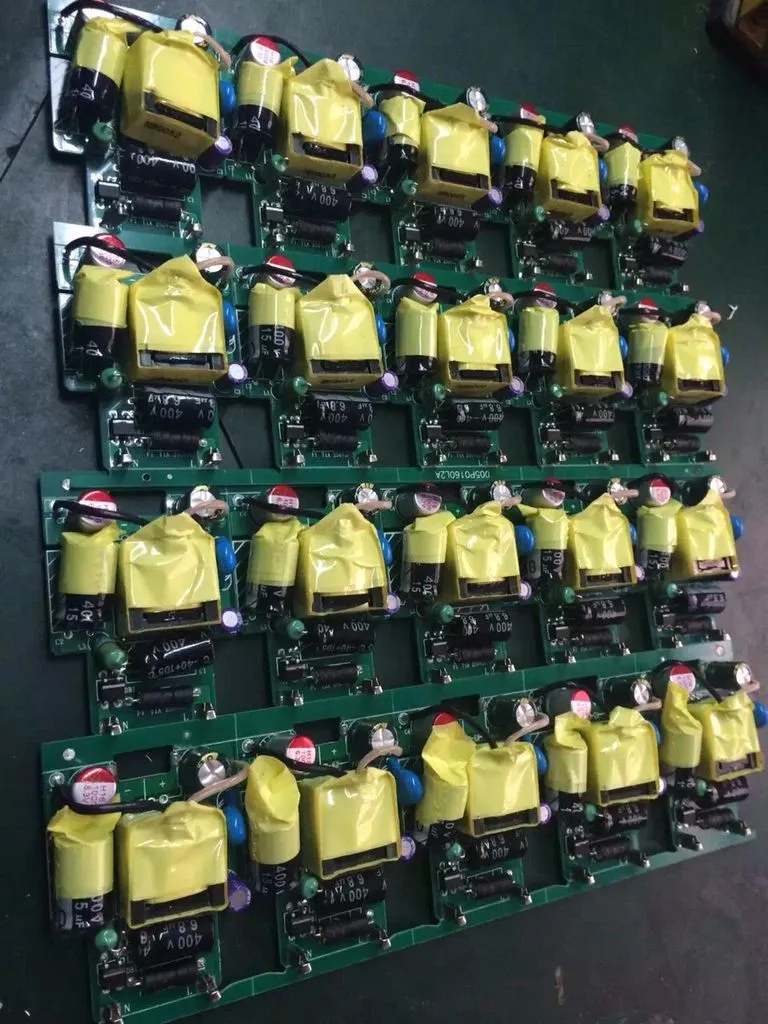

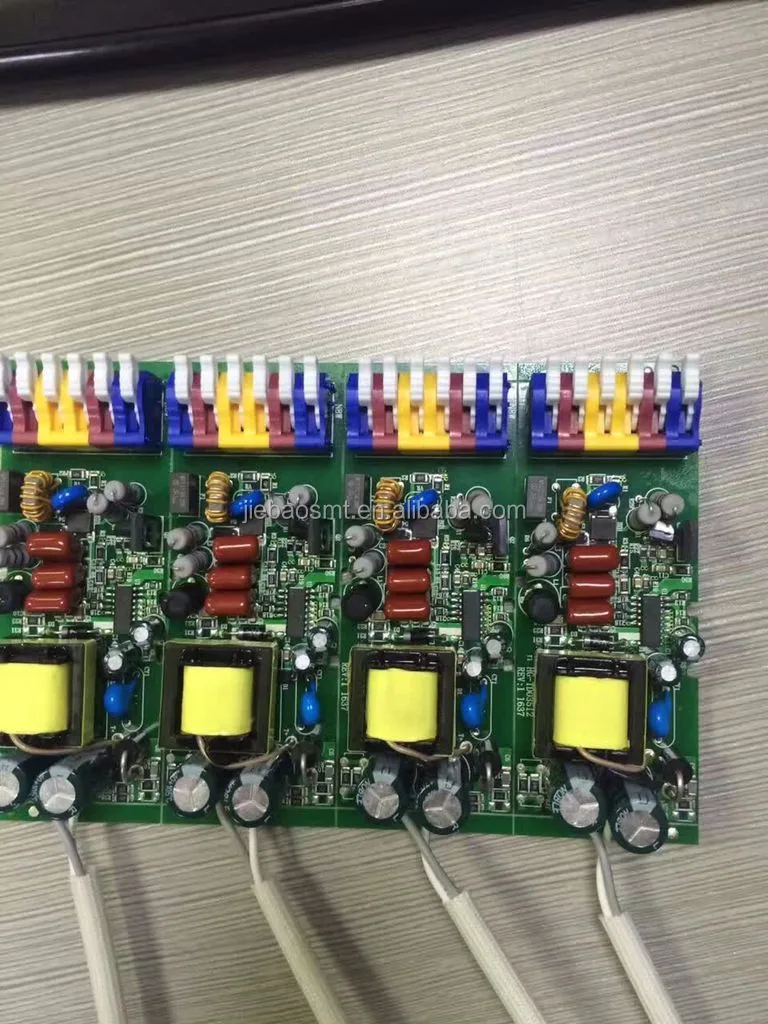

Customer picture

Certifications

Peripheral equipment

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Contact Info:

Winnie

Shenzhen Jaguar Automation Equipment Co.,Ltd.

Web: www.jaguar-ele.net

Tel:+86-755-23316315

Mob, Wechat, Whatsapp : +86-13530656876

Skype: Winnie Wu

Member Information

| Shenzhen JAGUAR automation equipment co.,ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18271470720 |

| Contact: | Tony (Sales manager) |

| Last Online: | 21 Apr, 2018 |

Related Products of this Company

-

Manufacturer Double Waves Automatic Pcb

US $1

-

smt mini reflow oven machine

US $1000

-

small manufacturing machines mini pcb

US $8000