Ceramic injection molding (CIM) has been practiced for more than 30 years, but has been restricted to niche applications with simple geometries such as the ceramic cores for investment casting. The manufacturing process of CIM is fundamentally similar to that of Metal Injection Molding (MIM), but contains subtle and important differences in its processing parameters.

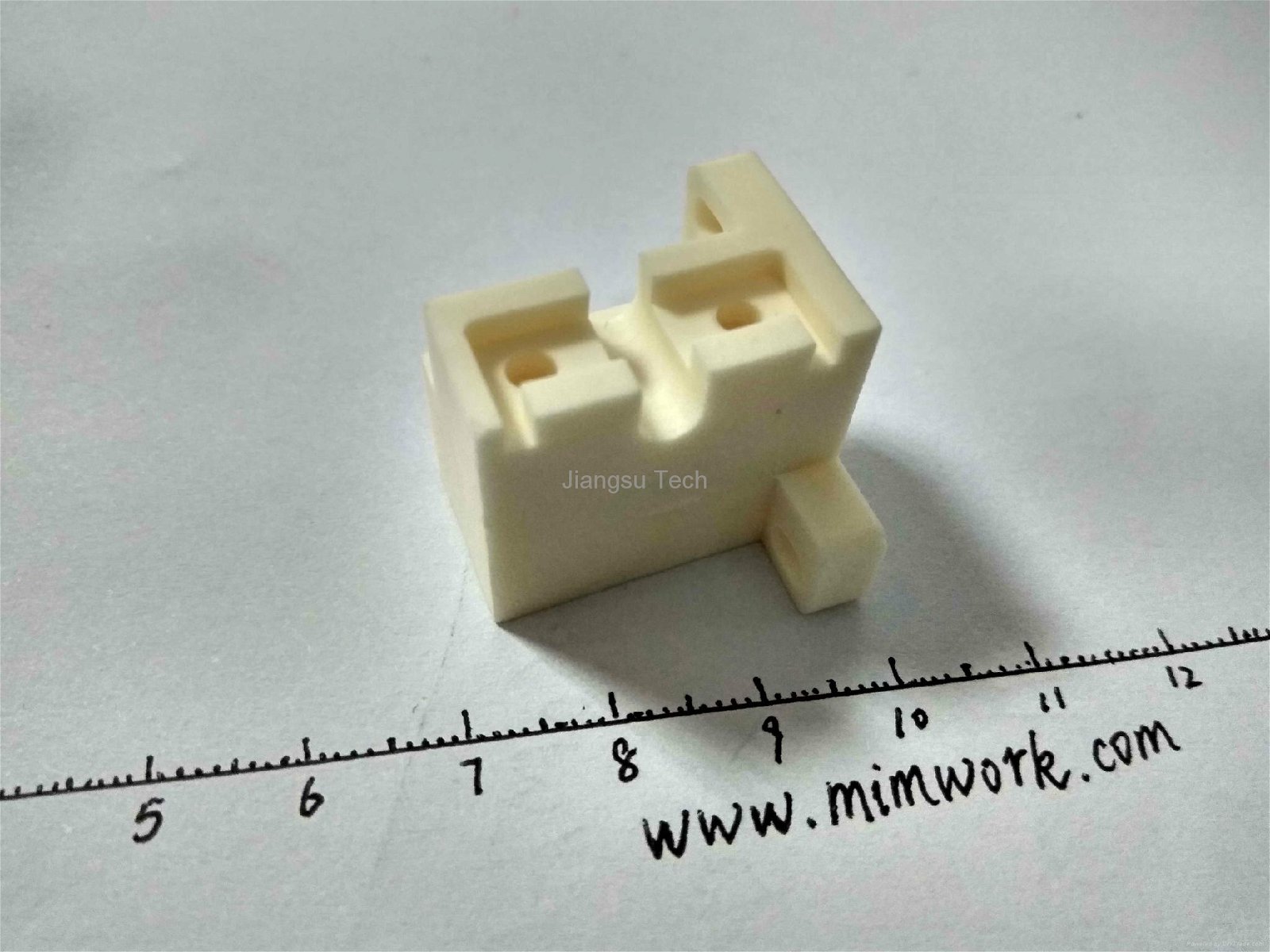

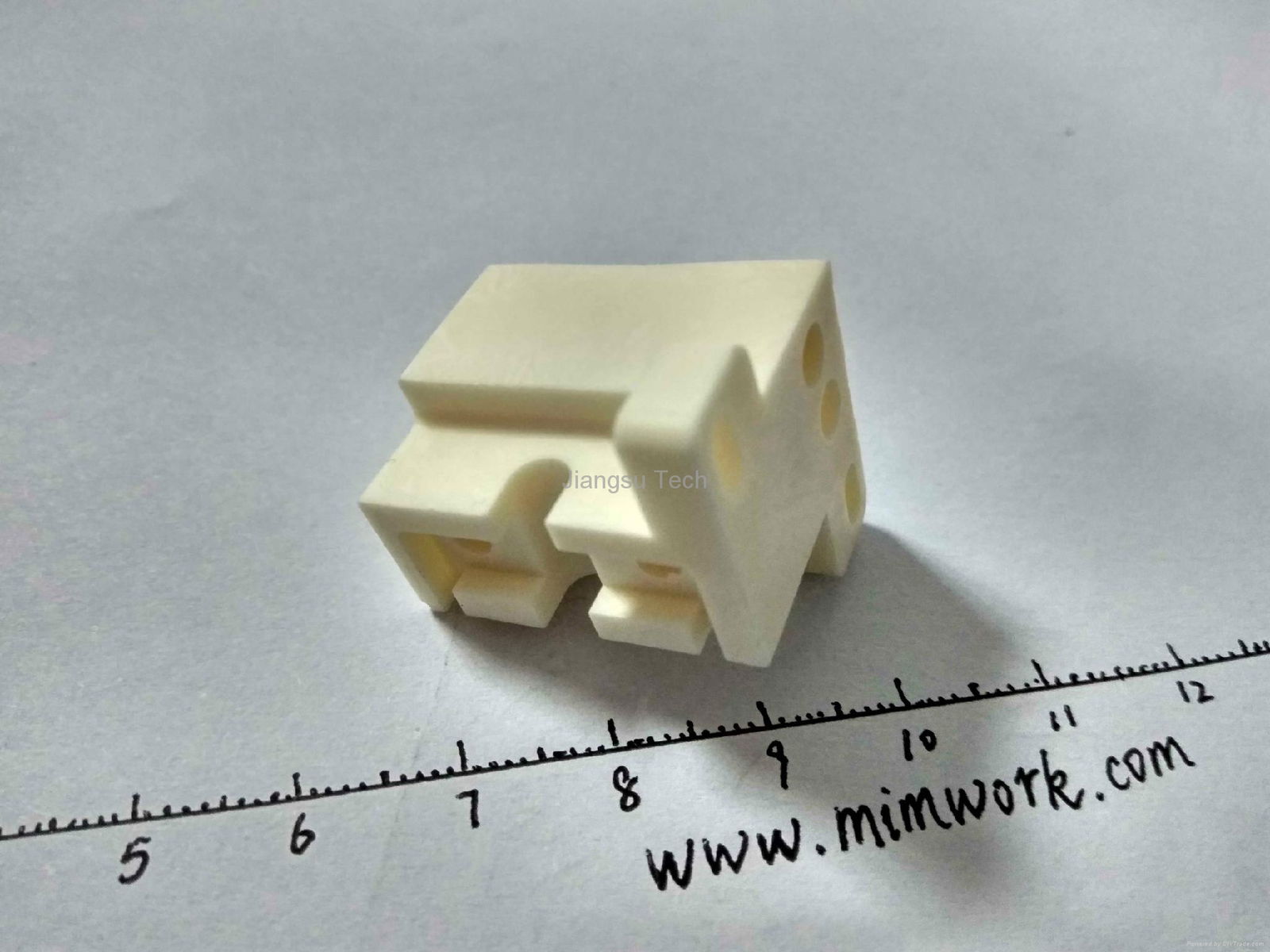

Jiangsu Tech is well positioned to overcome traditional manufacturing problems via the CIM process with developments in binder technology, feedstock productions, automated molding equipment, tooling design, sintering, and quality control systems. This process will enable the cost-effective production of parts with a range of geometric complexities.