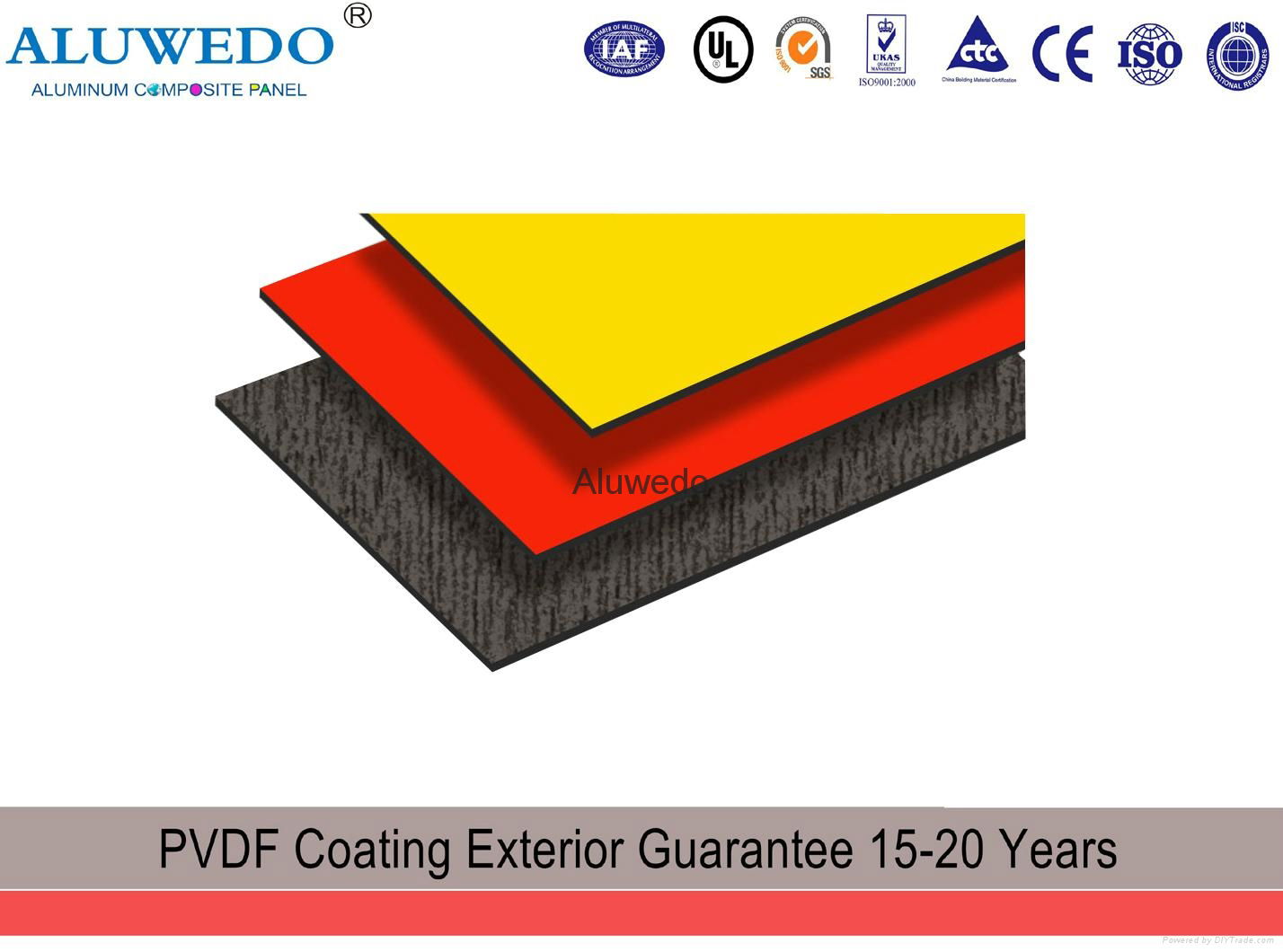

Aluwedo is comprised of two pre-painted sheets of aluminum with a solid polyethylene core

These create a durable printing surface for lasting outdoor signs and a variety of other applications

Panel specifications and dimensions:

Thickness: 2mm (0.08"), 3mm ( 0.12") 4mm ( 0.16") 5mm (0.2") 6mm ( 0.24")

Thickness recommended: 4mm (0.16")

Width: 850 to 2000mm, (34 to 80")

Recommended: 1220mm (48.8"), 1250mm (50"), 1500mm (60"), 2000mm (80")

Panel length as required

Aluminum thickness: 0.3mm (0.012") to 0.5mm (0.02")

*Custom width and length available upon request subject to minimum quantities

Recommended Dimension:

1220mm (4ft)*2440mm(8ft)*3mm ( 0.12")*0.21mm (0.08")

1500mm (5ft)*3050mm(10ft)*3mm ( 0.12")*0.21mm (0.08")

Fabrications:

Sawing:- with vertical panel saw, circular, compass or first saw

Drilling holes for joining:- with drill bits for aluminum sheet and plastic panels (for larger holes use a drill bit with locating point)

Routing:- with conventional routing equipment, to avoid pressure marks, please use plastic or wood vice jaws when chucking the work places

Shearing:- with a guillotine (check correct insertion of top cover sheet)

Blanking tools to be padded

Bending:- with folding table min

Inside bending radius r= 15*T (T=panel thickness) spring-beck effect higher than with solid sheet

Screwing:- with conventional stainless wooden, sheet metal and metal screws

For outdoor use, please take panel expansion into account

Folding (routing technique):- manually after routing V-groove on reverse side using panel saw with milling attachment or a hand milling cutter

Edges:- using file with rasp-like cut to file roughly cut contours lengthwise

Punching:- with steel band tool on punching base for panels of 2 and 3 mm in thickness

Pressing:- with brake press min. inside radius R = 15*T (T=panel thickness) spring-back effect higher than with solid sheet

Riveting:- with the usual equipment, using rivets or blind rivets

For outside use, pay attention to the panel expansion