| Model: | YYW |

|---|---|

| Brand: | Yuanda Boiler |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Boilers |

| Label: | thermal oil boiler , oil boiler , thermic oil boiler |

| Price: |

US $15000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Diezel/Diesel/Gas fired thermal oil boiler for asphalt heating/rubber/plywood

Product despriction

I. General introduction of Diezel/Diesel/Gas fired thermal oil boiler for asphalt heating/rubber/plywood

YY (Q) W series thermal oil boiler is a kind of boiler which uses gas(oil) as fuel ,thermic oil as medium, hot oil circulation pump to make the medium to forced circulation, deliver the heat to heating need equipments and then go back to the heating furnace.It can obtain a high operating temperature at low pressure and can do high-precision control on the medium.

This series boiler has compact structure. The heating area is constituted by close-knit coil pipes from inside to outside.Inside coil pipes are the radiation heating surface, and the outer surface of inside coil pipes and outside coil pipes form a convection heating surface.Fuel burn fully in the combustion chamber, the radiation heating surface absorb most heat, and then high temperature flue gas goes into convection heating surface to exchange heat, then go into the air preheater (or waste heat boiler) to heat the required (or water).at last, the low temperature flue gas discharges to the aerosphere through the chimney.

II. Advantages of Diezel/Diesel/Gas fired thermal oil boiler for asphalt heating/rubber/plywood

1).Three pass coil pipes design, thermal oil goes through the coil pipes and fire in the furnace-fire is surrounded by oil, which makes the boiler has big radiation heating area, highly improves the boiler efficiency and preventing deformation of boiler shell in high temperature heating.

2).Unique heating surface of the back of boiler--smoke turning around room is wet back design(smoke turning around room is surrounded with oil), which avoids dry heating of tube sheets and reduce heat loss.

3).Unique coil integration process, no gaps between coils, then Smoke will not be chaotic and short-circulate. Smoke flows long and smooth, makes the boilers heating enough and efficiency high.

4). Energy saving device design(air preheater, waste heater boiler or economizer is designed behind the boiler), which makes the exhaust temperature low and improves 10% of boiler efficiency.

5).Double-layer aluminum silicate insulation, makes the temperature of shell surface not more than 40C,which is energy saving and efficient.

6).Dislocation double sealing slot design,secondary leakage prevention, which seals very tight and avoid leakage.

7).Fast-setting and high-strength refractory building materials, strong solidification, long life cycle, and not easy to shake off.

8).Integrated wiring device(Junction box and wire groove), so that wire-controlled connection is more convenient, maintenance is more simple and more beautiful

after installation.

9).Outputting oil tank external design,slow down the rate of carbonization of fat and avoid accidents.

10).Roundness treatment for edges and corners of packing panels, which can prevent incidental injury accident in maintenance.

11).Double-door design and the smoke is removable, which are convenient for maintenance.

12).Professional and beautiful industrial stainless steel packaging design.

13).Independent research and development PLC control board, matching ability is strong.10-inch touch screen,easy, safe and reliable operation; Burner can

automatically ignite, flameout, switch small fire and big fire;Exceed 20% configuration for burner, ensures enough output, reduce equipment fatigue and extend

equipment life; high and low pressure protection; leakage protection.

14).High quality raw material supply---China famous big steel plant provide the raw material.

15).60 years boiler factory, mature technical and production team , which ensures the quality mature and stable.

Henan Yuanda Boiler Co.,Ltd

Contact Us:

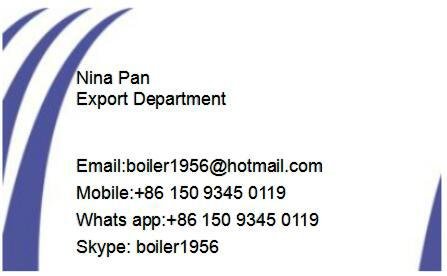

Attn:Nina Pan

Email:boiler1956@hotmail.com

Skype: boiler1956

Mobile:+86 150 9345 0119

Whats app:+86-150 9345 0119

Wechat:+86-150 9345 0119

| Payment Terms: | tt lc |

|---|---|

Member Information

| Henan Yuanda Boiler Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15093450119 |

| Contact: | Miss Nina Pan (Internationalmanager) |

| Last Online: | 27 Nov, 2017 |

Related Products of this Company

-

1 ton coal fired steam boiler

US $20000

-

1 ton oil fired steam boiler

US $20000

-

Coal fired 1 ton steam boiler

US $25000

-

1 ton oil steam boiler

US $20000

-

Diesel fired steam boiler

US $20000

-

Oil fired 2 ton steam boiler price

US $10000

-

6 Ton gas steam boiler

US $60000

-

Coal wood fired 4 ton steam boiler price

US $10000

-

4 ton gas steam boiler

US $50000

-

chain grate stoker 2 ton coal fired

US $35000