| Model: | Fluid Bed Dryer |

|---|---|

| Brand: | Eatge |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Drying Machine |

| Label: | fluid bed dryer , granulating machine , chemical equipment |

| Price: |

US $30000

/ pc

|

| Min. Order: | 1 pc |

Product Description

for more infomation plz contact me

Manager: Louis

QQ: 124512506

Email: louis(at)cq-eatge.com

Skype: louis(at)cq-eatge.com

Mobile Phone/Waht'sapp: 0086-18523068518

https://cq-eatge.en.alibaba.com/

http://cq-eatge.com/cn/

Location:Taojia Industrial Park, Jiulongpo District, Chongqing

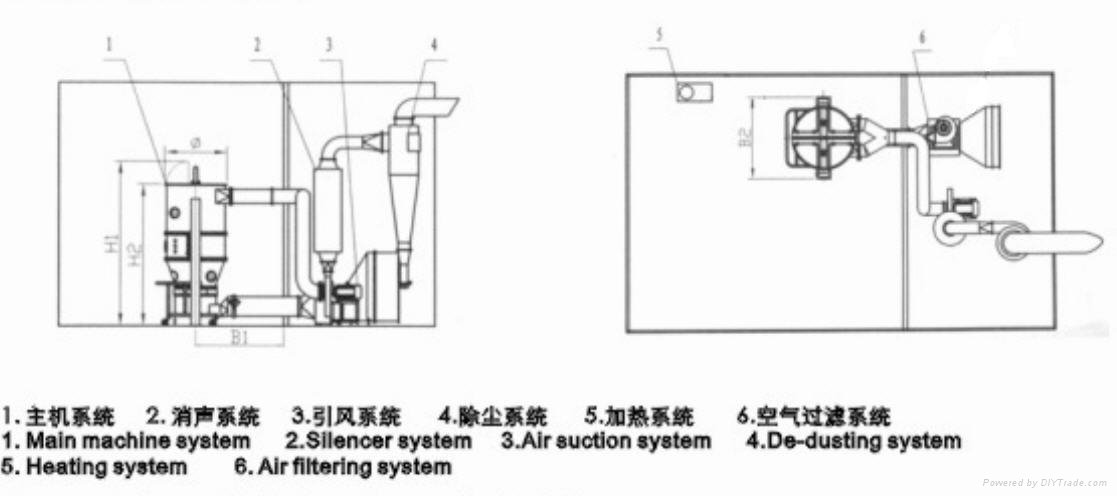

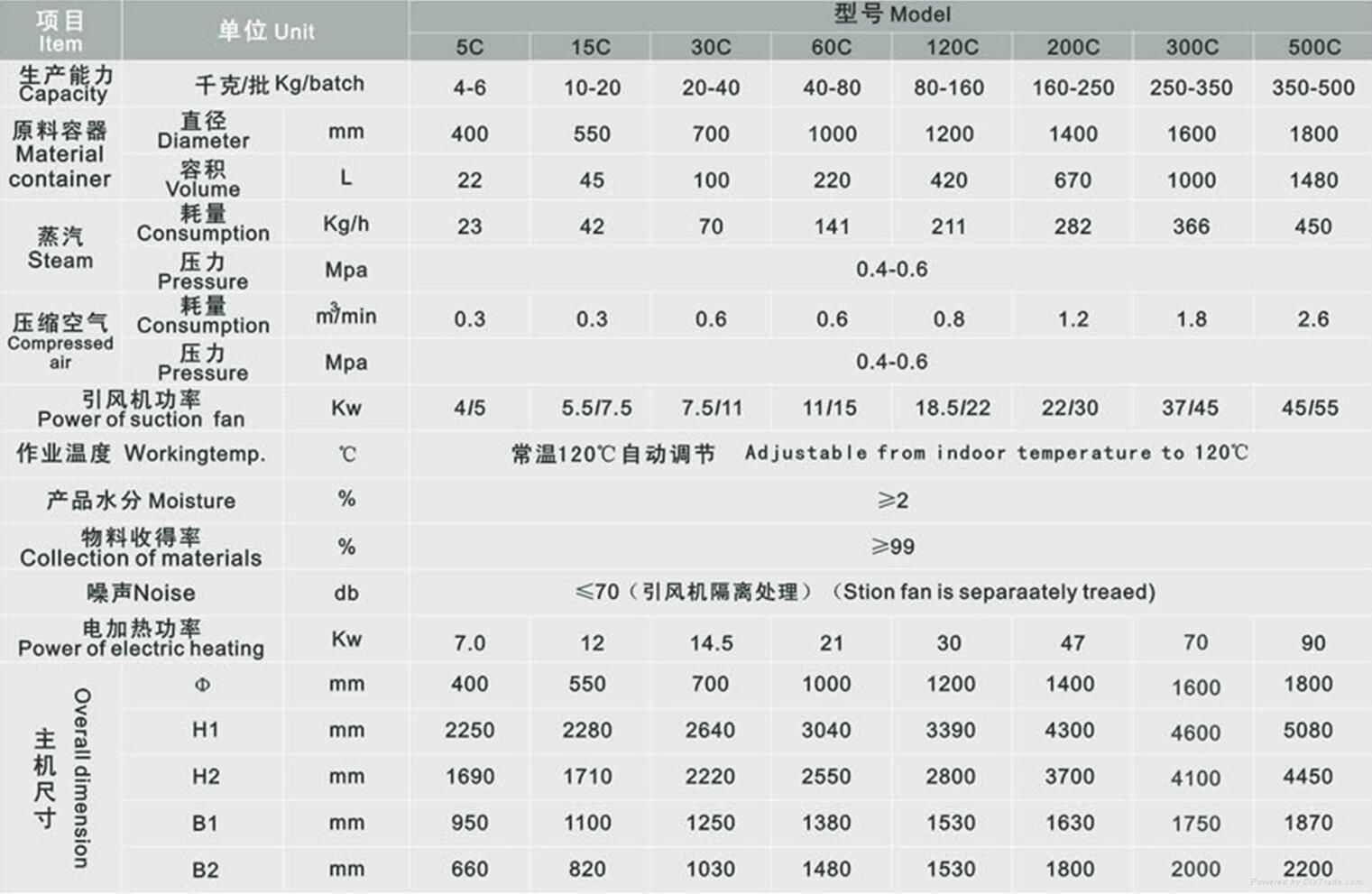

FG-C Series Fluid Bed Dryer 5C--500C

Usage of machine:

The material is suspended and forms the fluid state under the influence of clean and hot air

flow(negative pressure), and its surface fully touch with hot air, so it can be heating at any place inside the

container, which has reached the best hot exchanging state, so its efficiency is very high. When it is matched

with proper spraying system, and further improvement to structure, the fluid bed will become a technical

equipment which integrates drying, pilling, coating with solution, covering with powder and so on.

The machine has “Top spray” system, it is mainly used for mixing, drying, granules, “Top spray”

coating work of industries such as pharmaceutical, food, chemical and so on. While Spray Dryer Granulator

is used to produce Chinese Traditional Medicine that contain low sugar or sugar free

2,2 Technical introduction:

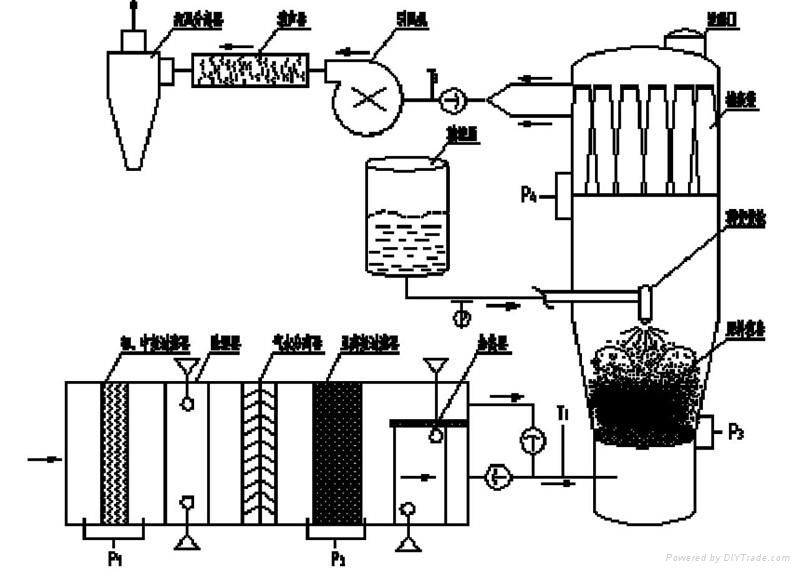

Top spray setting consist of material container and diffusing room. The material is pushed upward by

air flow to diffusing room, because the diameter of diffusing room is bigger, the fluid speed of air is low,

when the gravity of material can conquer the thrust of air flow, it will drop, and it can form the fluid state

according to this state. But the fluid state is not regular, it is not strictly controlled. This point is different

from bottom spray and tangent spray.

The liquid material is transported to system through spraying system, and then it is formed as fine drop

through spraying nozzle and then sprayed from upper to lower, its direction is opposite to the motivation of

material. The powder material combine with each other through the liquid bridge made by the surface

tension of liquid medium, and their volume is becoming bigger and bigger, at last, they will form the

granules with accurate size.

Structure and feature

- It is consists of operating end(touch screen) and a main control electrical case.

- The operating end case body should be put at operation room, it is confirm to the requirement of GMP. The

main control case body is put at assistant machine room.

- There are displaying meter, touch screen, and pilot lamb at operation end.

- In main control electrical case, it installed all the necessary control electrical machine such as PLC

procedure control machine, air switch, frequency convert machine relay,contactor,and all connecting line.

- PLC procedure control,Procedure model by hand and automatic procedure model, all necessary interlocking

protecting function.

- Set testing state and working state, and these two states interlock with each other.

- Condition setting of switch: only the air resource satisfy the setting requirements, the full machine and

electrical cabinet is well connected with ground, the system can work. When the air resource pressure is low,

it will stop providing liquid, when there is agglomeration phenomenon , it will start the functions such as

fiercely blowing at the same time that it stop providing liquid.

- Temperature, spraying air pressure, rotary speed of supplying liquid pump, the period for

cleaning powder and frequency, frequency convert of blower, pressure difference, the

setting and displaying of temperature.

Certificate of machine

-- The whole machine is made and designed according the rule of GMP, and we will provide the all

software information of GMP certificate of the machine.

- The manual for operating the machine

- Operation and maintaining manual and checking qualified certificate of matching parts of machine

- The installation introduction and drawing of machine (including installing drawing/principle drawing of

electrical machine and air motivation)

- Certificate of material to main material (including touching surface and non-touching surface of material)

- Check report of products of going outside our factory

- Check report of HEAP filter

- SOP standard operation of machine/ cleanness/maintaining process

- Electrical disc of documents needed by certificate, they are IQ,OQ,CQ,DQ and so on.

Packing and transportation

-Simply packed with case,which is confirm to the transportation safety.

- Transported by car(Chongqing—Port)

Payment: 50% Down payment:Before Production. Balance 50% paid before shipment

| Payment Terms: | TT/LC/WU/MG/PP |

|---|---|

Member Information

| Chongqing Eatge Machinery Manufacturing Co., Ltd. | |

|---|---|

| Country/Region: | Chong Qin - China |

| Business Nature: | Manufacturer |

| Phone: | 18523068518 |

| Contact: | Louis (Sales Manager) |

| Last Online: | 12 May, 2017 |

Related Products of this Company

-

PGL-C series spray dryer granulator

US $30000

-

Fluid Bed Dryer HL Series 100Liters Wet

US $30000

-

FL-C series fluid bed granulator dryer

US $30000

-

FG-C Series 120C Fluid Bed Dryer

US $20000

-

Multifunction Pilling Coating Granulator

US $30000

-

Fluid Bed Dryer HL Series 100Liters Wet

US $30000