| Model: | - |

|---|---|

| Brand: | hongtai |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Products |

| Label: | fused cast AZS , AZS brick , brick for glass |

| Price: |

US $1000

/ ton

|

| Min. Order: | 1 ton |

Product Description

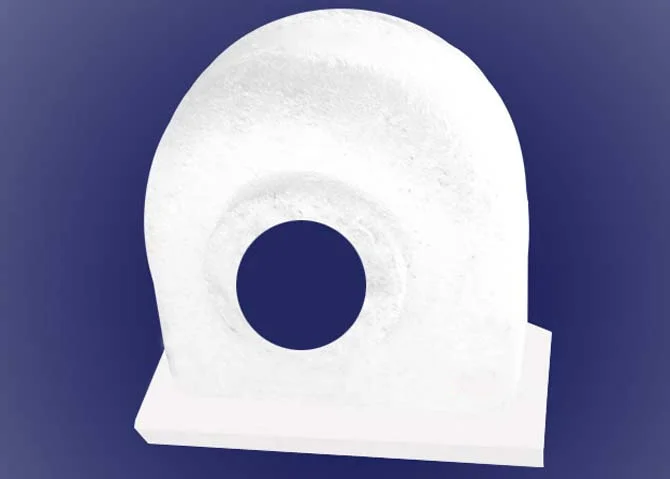

Refractory fused cast AZS Brick for Glass Melting Furnace

Refractory fused cast AZS Brick for Glass Melting Furnace is also known as corundum - oblique zircon products, the main chemical composition contains Al2O3 50% to 70%, ZrO2 20% to 40%, the rest of the SiO2. The main mineral composition is oblique zircon (ZrO2), corundum.

Advantages and Properties of refractory fused cast AZS Brick for Glass Melting Furnace:

1.Casted by melting raw material in the mold, then cooling and solidification.

2.Strong glass corrosion resistance and high thermal shock stability.

3.Good wear-resistance,drags-resistance and alkali corrosion resistance.

4.High-purity raw material, less pollution.

5.Top quality, long service time.

Chemical Index:

|

Physical chemical index |

41#fused Zirconia corundum brick |

|

|

SiO2 |

≤13.0 |

|

|

Al2O3 |

44--48 |

|

|

ZrO2 |

40--44 |

|

|

Na2O |

≤1.3 |

|

|

Fe2O3+TiO2+CaO+k2O |

≤2.5 |

|

|

Normal pressure strength(Mpa) |

350 |

|

|

Thermal expansion rate(%) |

0.8 |

|

|

Glass temperature C |

>1410 |

|

|

Glass corrosion resistance(1500 C 36H, common glass) |

≤1.2 |

|

|

Bulk density

|

Ordinary casting |

≥3.6 |

|

Inclined casting |

≥3.75 |

|

|

Non shrinkage casting |

≥3.9 |

|

|

0.2MPa Refractoriness under load C |

>1700 |

|

Application of refractory fused cast AZS Brick for Glass Melting Furnace:

Refractory fused cast AZS Brick for Glass Melting Furnace is widely used in the void free configuration:electrode blocks, submerged walls, throats, and in some cases melter sidewalls. Available as well, for sidewall application, in the specific "reinforced filling" version.

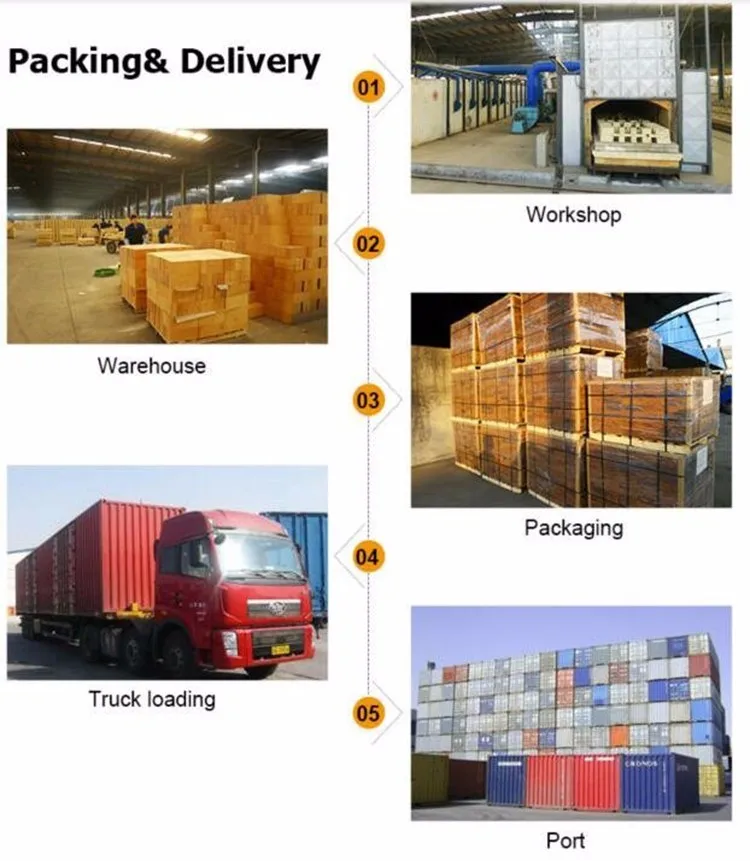

Packing details:

Refractory fused cast AZS Brick for Glass Melting Furnace is packaged with fumigated wooden pallet, using paper or non-woven fabrics between layers separated,plastic shrink film protected outside.finally using straps. Or as your requirements.

Shipping:

By vessel or train from Chinese ports.

Our Advantages

1) Whole production process lines from bauxite to varies grit sizes of brown fused alumina.

2) Strictly quality control system to guaranty a good quality.

3) All set of production certificates including ISO:9000, ISO:9001,ISO9001:2000

4) years reputation at mainland market.

5) Professional technical consultants to provide various industry solutions.

FAQ

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

2.Do you have any experience in exporting?

Yes,and now we have gained a global sales network reaching Taiwan, Russia, German, Korea,British,Egypt, Vietnam, Pakistan,Belagin, French, Greece, Spain, Congo, Angola, South Africa, and America, India and so on.

3. What's your delivery time?

It usually needs about 15days- 30 days after receiving the deposit.

4. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock, The quantity based on the material type, The buyer should bear all the shipping costs.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

For more detials, Contact Us!

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Henan Hongtai Kiln Refractory Co.,Ltd. | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18838001797 |

| Contact: | Marina Ma (sales) |

| Last Online: | 17 Apr, 2023 |

Related Products of this Company

-

refractory zircon brick for the high

US $500

-

Silicon carbide(SiC) brick for blast

US $800

-

Mullite Bricks for Cement Rotary Kiln

US $150

-

corundum brick for melting furnace

US $650

-

Insulation Corundum Mullite Brick for

US $800

-

silica brick for cement plants

US $500

-

ramming material for chemical industry

US $450

-

High temperature resistant refractory

US $500

-

White Fused Alumina for Metallurgy

US $500

-

mullite fine powder for refractory &

US $300