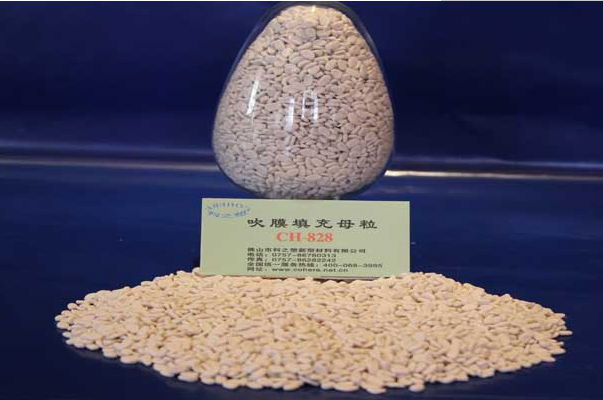

| Model: | CH-828 |

|---|---|

| Brand: | COHERE |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | masterbatch , filler masterbatch , calcium carbonated |

| Price: |

¥4.2

/ KG

|

| Min. Order: | 10000 KG |

Product Description

Product application

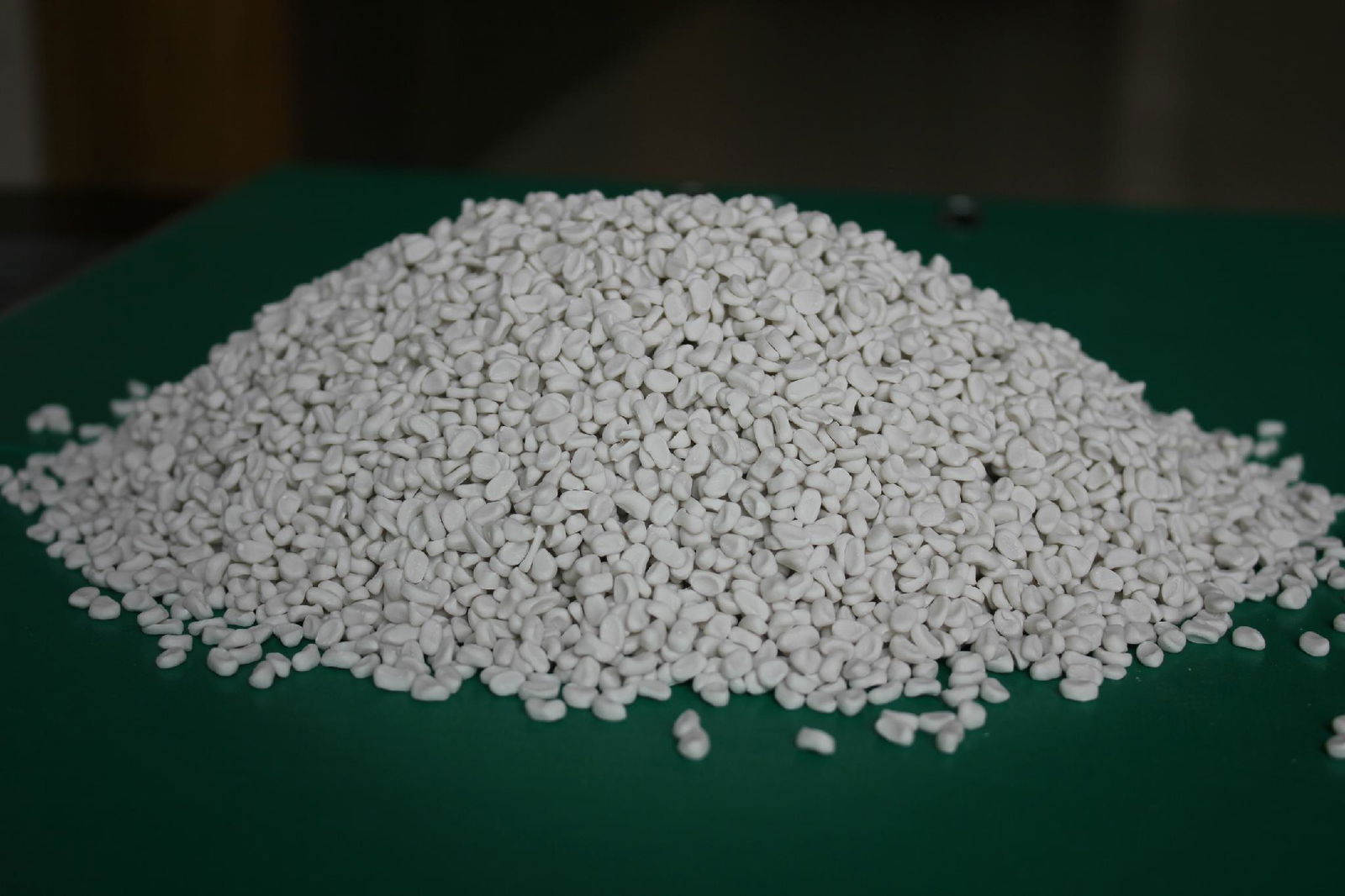

It is a plastic modifier that regards the sub-nanometer calcium carbonate superfine powder as the main raw material and optically combines the carrier, coupling reagent and bulking agent. In addition, it has good compatibility and dispersity and can improve the tensile strength of the plastics, dimensional stability and rigidness. It is a functional masterbatch with high performance, low cost and friendly environment. It applies to PE and PP injection molding, film blowing, coating film, PO and PP sheet and PP and PE pipe materials and Lichee grain filling and so on. As the calcium carbonate superfine powder is used, it has high lustrousness, low wear rate, surface modification and lipophilicity and can be filled in polyethylene, polypropylene and phenolic plastic and other polymers. It is widely applied to PVC cable filling. Plastics can be strengthened by this masterbatch and multiple mechanical properties of the rubber plastics can be improved, such as tensile resistance, tear resistance, abrasive resistance, and rot resistance. In addition, it can improve the flexibility and ageing resistance of plastics, improve the associativity of plastics and metal interface and increase the adhesive force and so on.

Product features

It has features of large filling amount and good dispersion effect. 10%-50% of filling amount is increased compared with ordinary calcium carbonate superfine powder. Plastics can be strengthened by this masterbatch. The masterbatch has comparative heat stability and dispersity and can obviously improve the material rigidness, toughness and bending strength. There is little impact on the electro-chemical property. Thus, products have good dimensional stability. In addition, the masterbatch can improve the system rheological property and reduce the contraction. The product surface should be fine and luster is good. The tension strength and scratch resistance and shock strength are greatly improved. The masterbatch is used simply and can be used with other original fillings together to reduce the production cost. Oil absorption (DOP) is low and has calcite structure with low specific surface. It has low wear value and no wear on the machine parts. The scale is not deposited on the screw. It improves the printing property and has good color fastness.

Application scope

It is widely applied to the plastic pipes, proximate matters, plastics-steel doors and windows, cables, cable sheath, water supply pipes, vehicle bumpers and the plastic casing panels of air conditioning, refrigerator, television, computer and washing machine and other household appliances. Moreover, it is applied to film blowing, coating film, PO, PP sheet and PP, PE pipe materials and Lichee grain filling and so on.

Member Information

| Cohere (Foshan) Advanced Material Co. Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18825954921 |

| Contact: | Zhang si (Marketing manager) |

| Last Online: | 12 Feb, 2020 |