|

TECHNICAL PARAMETERS

|

| Model |

QY-SC20-YA1 |

QY-SC30-YA1 |

|

| Laser Power |

20W |

30W |

| Laser Wave - Length |

1064nm |

| Beam Quality |

M2: <1.5 |

| Laser Repetition Frequency |

20KHZ - 100 KHZ |

| Standard Marking Area |

110×110mm |

| Marking Area Option |

50 *50 mm / 170*170mm / 200*200mm |

| Marking Depth |

<0.4mm |

<0.5mm |

| Marking Speed |

< 10000mm/s |

| Minimum Line Width |

0.01mm |

| Minimum Character |

0.15mm |

| Repetition Precision |

0.002mm |

| Power Consumed |

400W |

| Power Supply |

220V±10% 50Hz/4A |

| Cooling Way |

Air Cooling |

| Control Link |

USB |

ACCESSORY.

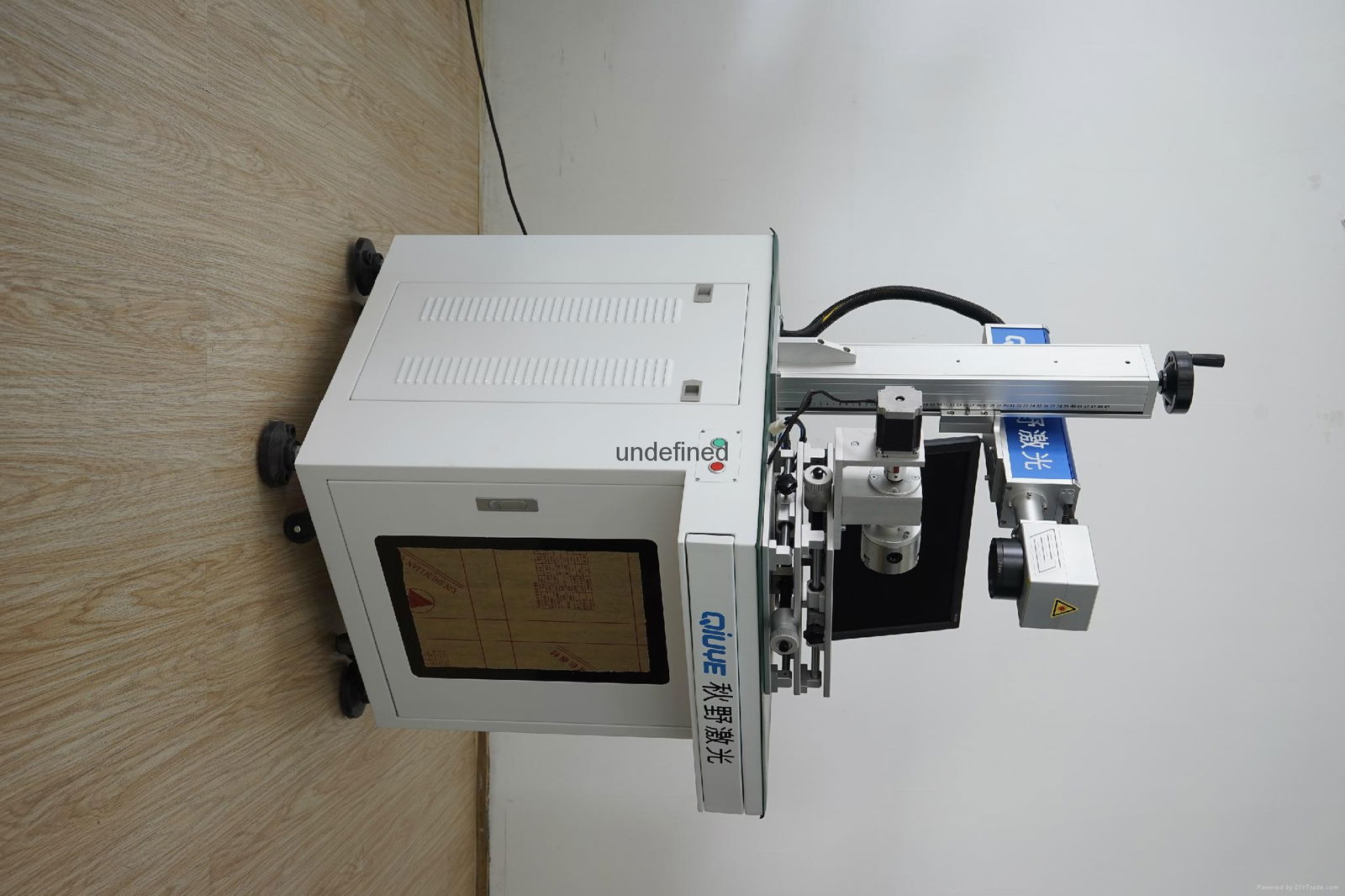

1. Metal Plate equipment cabinet. ( suitable for marking small, medium and large-sized metal parts)

2. High precision pillar stand. ( gap-less upward/ downward position setting, smooth movement with high precision. )

3. Portable operation head for easy movement.

4. Laser device. ( the service life is more than 100000 hours, maintenance-free, low power consumption. )

5. High speed digital scanning galvanometer. ( superior quality, fast printing speed, high control precision, maintenance -free. )

6. Field lens. ( high purity lens with professional coating for terrific luminous efficiency and luminous intensity. )

7. Computer with marking software provided.

8. Displayer.

9. Wireless keyboard and mouse.

10. Marking control system.

11. Professional power supply switch.

12. Height adjustment bracket of the operation head for the easy use of operator.

PRODUCT FEATURES.

1. Totally enclosed design, free - maintenance laser optical system.

2. Elaborate beam spot, superior quality, steady power, long service life, low energy consumption.

3. Fast marking speed with accurate and excellent marking performance.

4. Available for use in different occasions, suitable for marking precision parts.

5. Patented and superior configuration, cost - effective, convenient and and quality assured.

6. Reserved port for connecting the automatic production line or the automatic inspection equipment for improving the working efficiency.

7. Professional technology support and long after- sales service time.

8. Suitable for marking small, medium and large- sized workpieces, for large and medium-sized workpieces, take down the operation head to work the marking on the surface of large and medium-sized workpieces, for small workpieces, keep the operation head on the machine and put the small-sized workpieces on the stand being marked directly.

9. Easy to carry and remove.

APPLIED MATERIAL.

1. Stainless steel, aluminum, copper, iron, aluminum alloy, all kinds of alloy and all kinds of metal.

2. PP, PE, PS, PF, ABS, PVC, resin, rubber, etc.

3. On all kinds of the processed surface such as spray paint, powder coating, oxidation, electrophoresis, etc.

4. Stone, coloured paper, coloured acrylic, etc.

MARKING PERFORMANCE.

|