| Model: | LN-2200-6000 |

|---|---|

| Brand: | Lanning |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | tyre pyrolysis , tyre recycling , plastic pyrolysis |

| Price: |

US $30000

/ set

|

| Min. Order: | 1 set |

Product Description

Product application:

This machine can recycle waste rubber/tyre/plastic to fuel oil and carbon black.

End product:

1. Fuel oil from waste tire are used in below industries

A. power plant factory

B .glass factory

C. cement factory

D. ceramic factory

E. aluminum factory

F. boiler factory

G. central heating factory

H. painting factory

2. Carbon black from waste tire are used in below industries

A. electric cable jacketing

B. conveyor belt

C. hose and doormat

D. black nylon bag

E. rubber additives

F. automatic spare parts

G. heat isolation

H. black colorant in rubber materials

I. plastic pipes

J. industries rubber products

K .fire fighting

Advantages:

1) Q245R steel, auto-welding

2) 42-45% oil yield for tire,60%-70% for plastic

3) carbon black auto-discharging

4) waste gas recycle system, energy-saving

5) Eco-friendly design

6) auto-alarm and safety valve devices

7) catalyst formula provided

8) free installation

9) 6 years life for the host reactor

10) new condition,factory direct sale, best price

11) running machine can be visit.

Process chart:

Put waste rubber,tyres, plastics into the reactor and close the door. Then,begin heating the furnace with coal, wood, heavy oil or gas. When temperature rises to 150 centigrade, some waste gas will be output. Then the temperature continues going up to 220 degree, lots of quality oil gas starts coming out. The heavy oil residue falls into the heavy oil tank while the light oil gas goes through the sub-air package and cooling pool, finally be liquified to oil and stored in the oil tank. so we get heavy oil and light oil.

Detailed images:

Main parts:

Models:

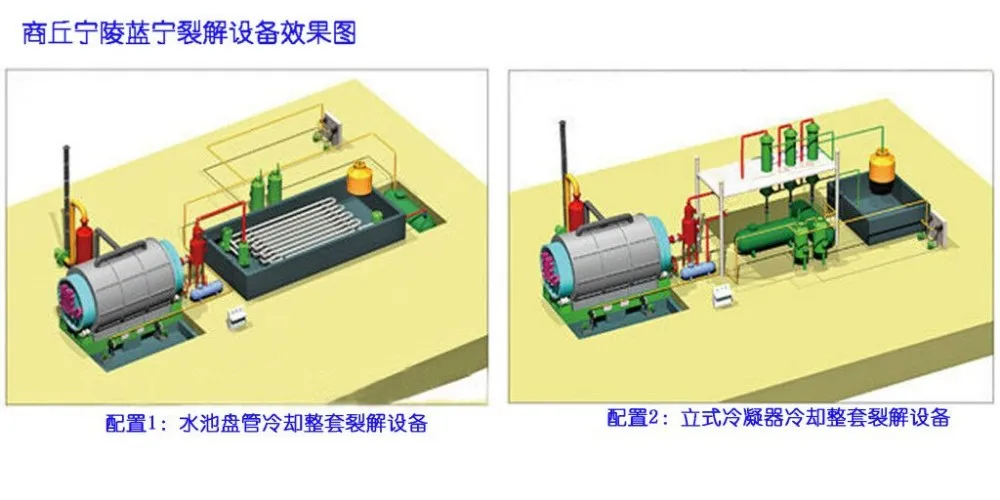

Coil pipes cooling Condensers cooling

Packing containers

|

Item |

capacity |

40’ HC container |

40’ FR container |

|

LN-2200-5100, |

5 tons/batch |

2 sets |

/ |

|

LN-2200-6000 |

6 tons/batch |

2 sets |

/ |

|

LN-2200-6600 |

7 tons/batch |

2 sets |

/ |

|

LN-2600-6000 |

8 tons/batch |

1 set |

1 set |

|

LN-2800-6000 |

10 tons/batch |

1 set |

1 set |

|

LN-2800-6600 |

12 tons/batch |

1 set |

1 set |

Delivery time: 15-20 working days after the deposit received

Installation:

For each set of machine, one installation engineer will be sent to your local to guide the installation, commissioning and staff training for free.

FAQ

Q1: What kind of raw material can be used?

waste tyres/ rubbers/ shoe soles/ inner tube / cable husk/ bicycle tyre/ motorcycle tyre; PP,PE,PVC,PMMA plastic, paper mixture from paper mills and all kinds of waste nylon products.

Q2: What are the end products?

If your raw material is tyres, end products are fuel oil, carbon black,steel wire and waste gas;

if your raw material is rubber or plastics, then end products are fuel oil, carbon black and waste gas.

Q3: What's the fuel of pyrolysis plant?

The fuel can be coal, charcoal, firewood, fuel oil, heavy oil and natural gas.

Q4: What's the covering area of one set of 5-10 ton capacity pyrolysis plant?

The equipment covers 30 square meters(length20m*width15m). Besides raw material and end products storage areas,you also need to prepare workers' resting room and simple office, so totally 600-800 square meters land will be better.

Q5: How many workers needed to operate the plant?

3-4 workers are enough for one set of pyrolysis plant. If you use auto-feeder and auto-discharging system, then 2 workers are ok.

Q6: How about the installation?

We will provide the foundation drawings to you after the deal is done and send technical engineer to guide the installation, the commissioning and workers training on your working site.

Q7: What about the usage of the oil extracted with this plant?

The oil from tyres or plastics is mixed oil. It is a good quality furnace oil, used as heating oil.

It can be used for some large boilers, like iron and steel plant, bricks factory, cement factory,glass plant and etc.

Q8: The extra waste gas could not be emitted directly to the air, as it would get accumulated in the surroundings,

and even a single spark can lead to blast.

Don't worry! There is waste gas recycle system. Waste gas will be recycled to the chamber to heat the reactor.

Contact:

annie

Tel/wechat/whatsapp:+86 18837001682

QQ:960556971

Member Information

| Ningling Lanning Technology Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18837001682 |

| Contact: | Lee (sales) |

| Last Online: | 29 Jul, 2017 |

Related Products of this Company

-

used tyre pyrolysis Machine

US $35000

-

Waste Oil Sludge Recycling Machine

US $36000

-

Used tyre recycling machine to oil with

US $36000