| Model: | RZCRT5-2516EF |

|---|---|

| Brand: | Rui Zhou |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | Sofa cutter , Clothing fabric cutt , PU cutter |

| Price: |

-

|

| Min. Order: | - |

Product Description

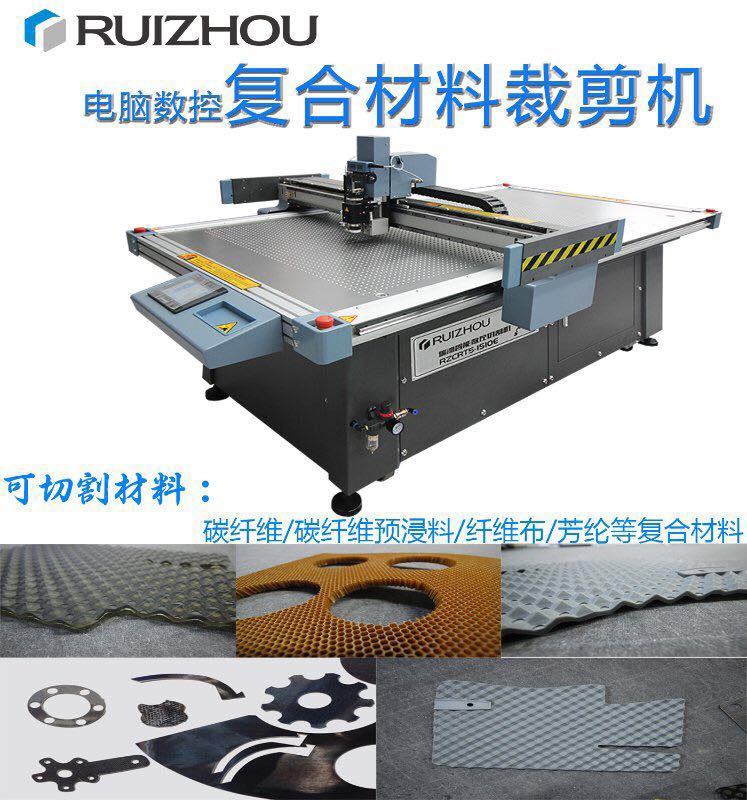

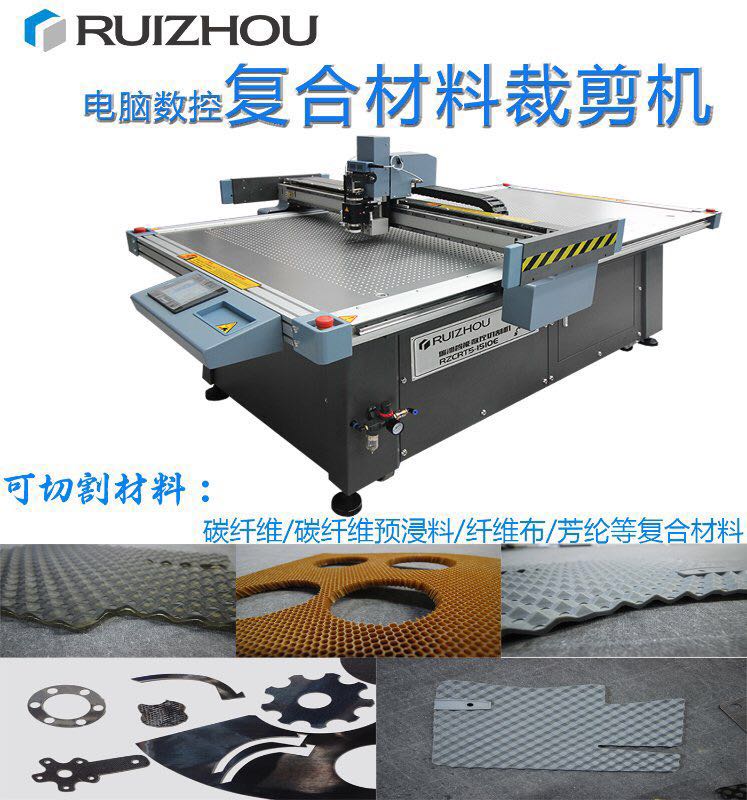

Product description:

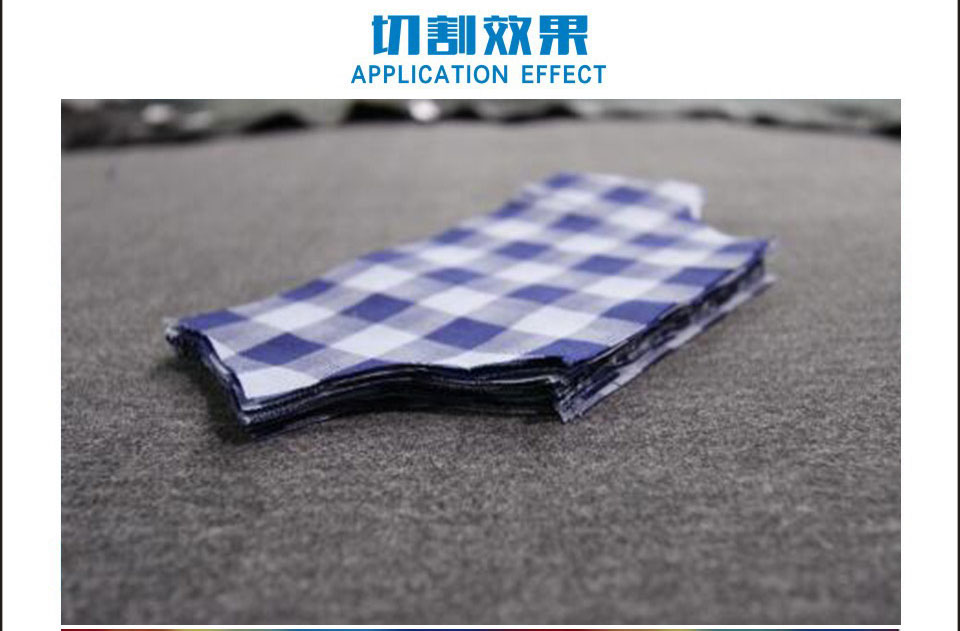

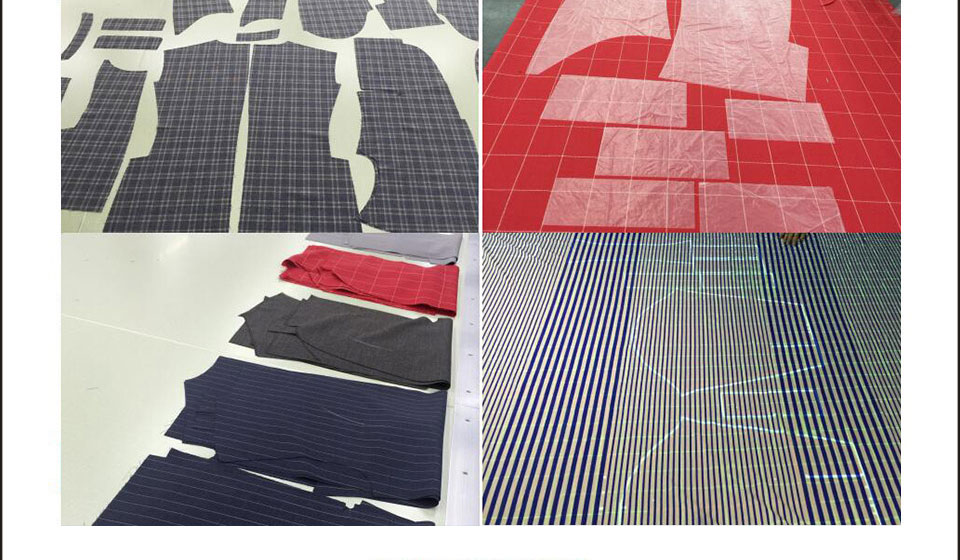

When the line drawing, drawing, text annotation, indentation, half cut, full cut, once completed. Meet small batch, multi order, multi style production goals.

This programmable multi axis motion controller, stability and maneuverability to domestic and foreign advanced technology level.

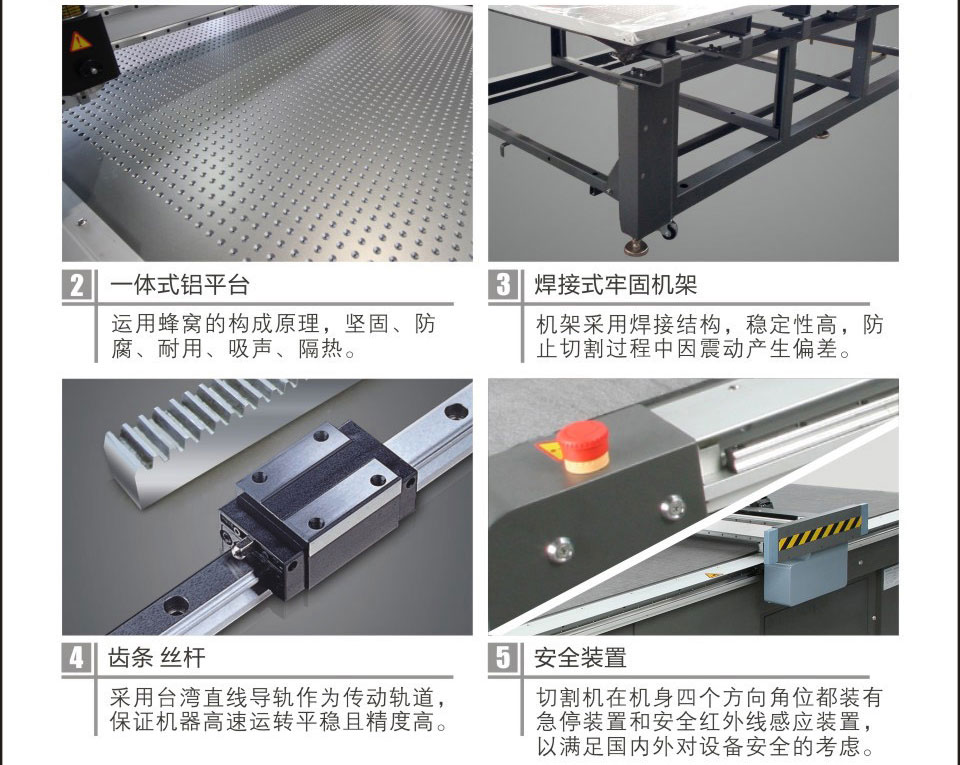

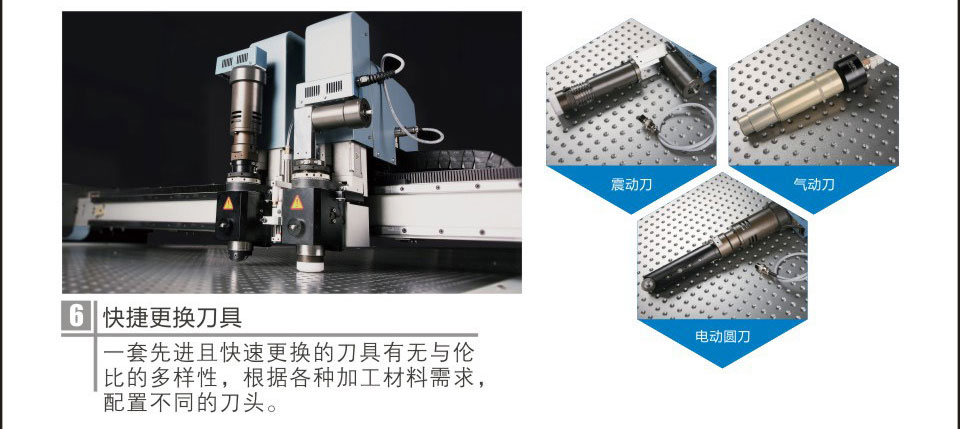

This cutting machine drive system adopts imported linear guide and rack, synchronous belt, the cutting precision can reach the origin of zero error.

This friendly HD touch screen man-machine interface, convenient operation, easy to learn. Standard RJ45 network data transmission, fast, stable and reliable transmission.

It is widely used in shoemaking industry, clothing industry, composite materials, l age industry, automobile industry, printing industry, electronic industry, decoration industry, furniture industry, etc..

Two. Detailed description of the machine:

| Payment Terms: | 30% down payment, 70% shipment paid |

|---|---|

| Embed HTML Code: | |

Member Information

| Guangdong Ruizhou Technology CO.,LTD. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15999852850 |

| Contact: | Cai Manager (Marketing Center Man) |

| Last Online: | 17 Oct, 2023 |

Related Products of this Company

-

Leather cutting machine, leather cutting

-

Automatic feeding cutting bed of

-

Electronic accessories cutting machine,

-

Carbon fiber prepreg cutting machine

-

Kraft cutting machine, rubber plate

-

Special cutting machine KT board EVA

-

Kt / acrylic plate cutting machine

-

Rui Zhou technology - automotive floor

-

Rubber plate cutting machine, PVC board,

-

Leather cutting, case cutting machine,