| Model: | LN-10 |

|---|---|

| Brand: | Lanning |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Filters |

| Label: | oil refinery , waste oil refinery , waste oil recycling |

| Price: |

US $39000

/ pc

|

| Min. Order: | 1 pc |

Product Description

The real picture of plant

Features and advantages

1. PLC automatic control system

2. Full-vacuum processing enviroment

3. Automatic rolling machine makes the circle perfect.

4. Rigorous test system to guarantee the quality of the product and it's accessories.

5. Non pollution, ZTE series desulfurization device.

6. Humanity design, automatic carbon black discharging system, time-saving and labour-saving.

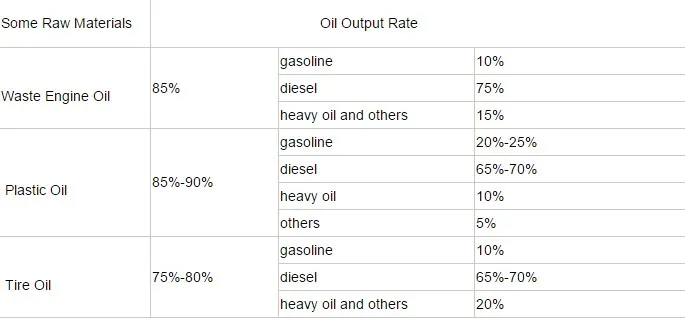

Some available raw materials and oil output rate

advantage service

Reactor:

1. The gear can be seperated from reactor, instead of welding on reactor. So it will not be destroyed by cycling heating. and very easily to be re-placed

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q245R/ Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

Auto-feeder(optional device):

1. 50 ton hydraulic pressure help feeding more raw materials.

2. The diameter is 1.4m. It can feed all kinds of raw materials, including plastic, packages of plastic, truck tire,

car tire, or tire pieces after cutting.

3. Save labor, save time.

4. After finishing production it can feed raw material instead of waiting the reactor to be cooled.

Catalyst chamber:

1. Improve the oil yield and oil quality.

2. Impurity of oil gas will be collected here.

3. Reduce the speed of oil gas so that it will be better cooled.

Oil separator:

1. Water from raw material will be separated here.

2. Water sealing design prevent tempering. Ensure saftety.

3. Heavy oil will be collected here.

Cooling system :

1. Coil pipe cooling system : there are 22 pipes lied in the water pond,each pipe 6 meters long, oil gas can be

cooled in larger area and longer time,thus get higher oil yield .

2. Vertical condensrs : we supply 4 cndensors, each has 44 pipes inside the condensors. Save land and

looks more neat and beautiful.

Anti-back fire device:

1. Little residual gas can not be cooled. It will recycle these gas to furnace burned to heat the reactor.

2. Water sealing disign will prevent tempering. Ensure safety.

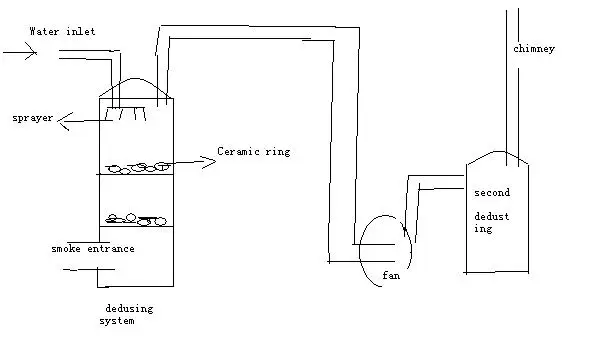

Double dust removal device:

1. Dispose of flue gas caused by heating reactor using coal, wood, oil or natual gas.

2. Environment protection.

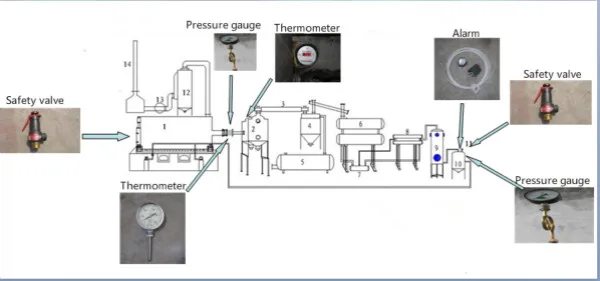

Safety system:

After-sale service:

1, we are responsible of machine installtion and deb ing

2, Engineer will assist buyers producing and training workers.

3, Guarantee period for equipment (including accessories) is one year.(Except personal factor damage and quick wear -part). For all standard and non-standard parts, if damaged under normal production during work according to our manual, we will offer deploy unconditionally. For reactor Guarantee period is 4-8years

Finished Products

Certifications

Delivery & install

- engineer service available

- install the machine

- trial running

- train workers how to operate

FAQ

What is the Warranty period given by you for the whole plant and machinery?

We guarantee the complete machine for one year since installation. If during the first

year, there is any problem caused by the machine quality (Except personal factor

damage and quick wear -part), we take responsibility.

Total machinery will fit in how many containers?

That will depend on which model will you choose. For LN5,(5 capacity/per day), two 40 feet high containers are ok. But for one larger than LN5, for example ,LN-10, one 40 feet high container and one 40 feet FLAT RACK will be required.

When will we receive the foundation drawings?

After signing the contract, we will send the foundation drawing to you OR make a design according to your workshop size .

How much is your installation time?

About one month including installing the machine, testing the machine, and training your

workers until everything runs smoothly.

How much civil work will be involved?

Only two. One is the foundation for the reactor base, the other is the water cooling pool if you choose the coil pipe cooling system.

Member Information

| Ningling Lanning Technology Co.,LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18837001680 |

| Contact: | Kelly Feng (Sales Manager) |

| Last Online: | 05 Dec, 2017 |

Related Products of this Company

-

High Efficient safety device waste

US $35000

-

High quality factory direct high

US $38000

-

Used motor oil waste engine oil

US $90000

-

Non-pollution pyrolysis waste oil

US $41000

-

High profitable hot sale waste engine

US $35000

-

New technique high quality continuous

US $98000

-

High quality factory direct quick

US $42000

-

New technique hot sale automatic

US $88000

-

Factory sale Best price Eco-friendly 90%

US $85000