http://youtu.be/N8IvIkPQ4hs

A glance at our company

1. Wide range of capacity options:

The optimal design satisfies the common bottle shapes and labeling requirements, covering the standard capacities, from 3,000 BPH to 60,000 BPH.

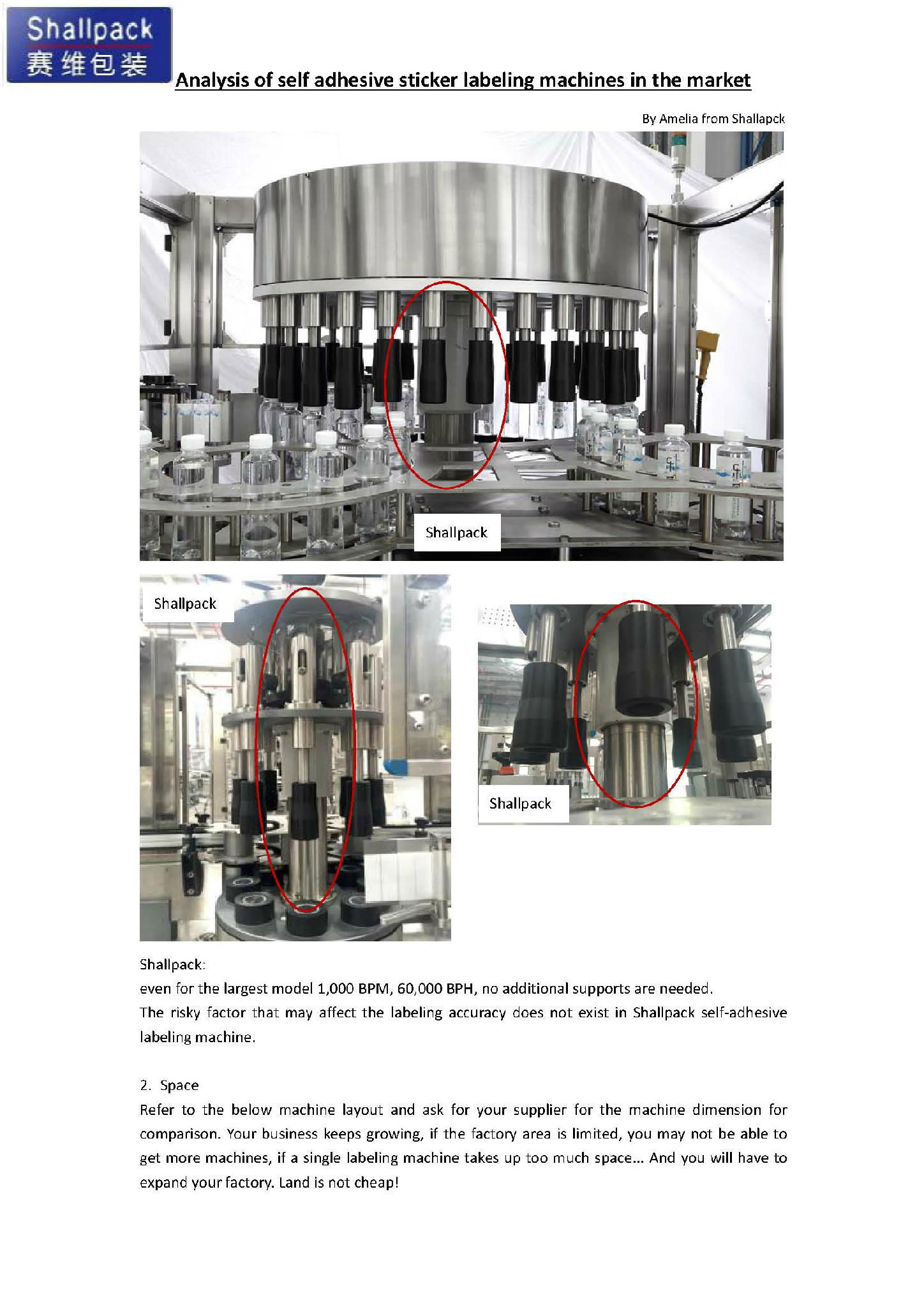

2. High stableness:

Stable operation of the machine is a basic requirement for the client. The stableness of the machine affects the fabrication effectiveness of the whole production line and of the management, and the maintenance cost.

Shallpack never stops improving its labeling machines. Based on the fabrication data in clients’ factory, the machine operation effectiveness ≥95%.

Application: 36000 BPH production line, monthly effectiveness: 98.9%

3. Easy operation:

User-friendly HMI is easy to operate. Misoperation can be avoided.

4. Optimal design does not require much maintenance:

The structure has been optimized for quick change-over, without requiring tools. Change-over time ≤15min.

Centralized lubrication and automatic lubrication design saves the maintenance and repair time.

Label reel change-over device shortens the change-over time to less than 15 seconds. The fabrication will not be affected during the change-over.

5. One single machine for a variety of applications

For 2 dimensional labeling area, Shallpack hot melt glue labeling machines adapts to a variety of bottle shapes: round, square and oval. The bottle material can be plastic, glass and metal. The label material can be paper, BOPP, OPP and PET. A single machine can label different designs, with positioning and non-positioning labeling functions in the same machine.

Minimum label thickness: 0.025mm.

6. Options:

1)Automatic splicing device of label carrier films:

Automatic splicing of label carrier films

Non-stop labeling

Safe fabrication

Adding a new label reel at any time

2) Camera detection and elimination device

Check the label accuracy

Detect label missing

Check the bottle liquid height

Identify the bar code or QR code

Eliminate unqualified products

3)Label missing detection and elimination system

Automatic label missing detection

Automatic high speed elimination system

Improve product quality

Reduce labour intensity

4)Detection of ends of label reels and elimination system

Fast detection of ends of label reels

Automatic non-stop elimination

Guarantee product quality

Increase fabrication effectiveness

5)Servo label positioning device

Wider application for a variety of bottle designs

Faster change-over between different bottle designs

6) Blowing labeling device

Labeling empty bottles before filling

7) Custom fabrication for non-standard labeling

With 3 decade experience in labeling machinery, Shallpack provides high quality customization service.

8) After-sales services of long term, high efficiency and good quality

One year warranty of the machine

One year free wear parts

Life long maintenance

9) Sustainable technical upgrade services

10) Comply with UL, CE, CCC certifications

Electrical devices and components

Devices and components Brand & Specification

Electrical control cabinet Stainless steel cabinet with RACK air conditioner (specially for cabinet), SIMATIC 9inch Multi-color HMI (touch screen)

Motion control system ELAU

Main drive motor Germany SEW

Standard electrical components Schneider SIMATIC WAGO

Label anti-deviation system Germany E+L automatic label anti-deviation system, anti-deviation precision to 0.01mm

Label detector Colorful-label sensor

Label tension control system American Warner automatic tension control system

Speed control: with automatic speed control mechanism

Mechanical reticulate gluing system: One (1) kilogram glue can be used for 100, 000 pieces of labels (width of label is 50mm)

With stainless-steel coated on the whole machine

Power consumption

lVoltage of main power supply: 380 V/50Hz, 3-Phase

lControl Voltage: 220V AC/24 DV

lPower: 20 Kw

Gas

lAir pressure: 0.6 MPa

lConsumption: 200 NL/min