| Model: | - |

|---|---|

| Brand: | Sandry |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cast & Forged |

| Label: | resin sand mixer , furan resin sand , resin coated sand |

| Price: |

¥90000

/ set

|

| Min. Order: | 1 set |

Product Description

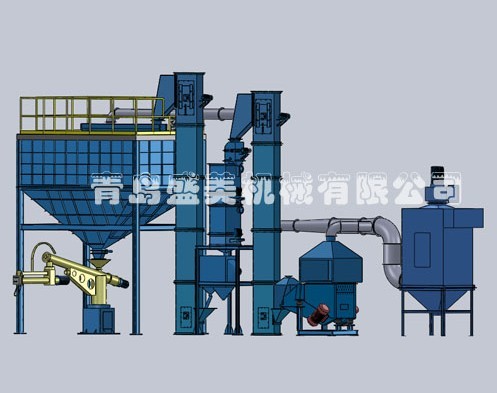

Resin sand foundry line 10ton sand preparing per hour

Product Description

Specifications

Turn key solution

ISO9001:2008

Flexible payment term,turnkey solution

Mature engineer team

Good quality good price

Resin sand reclamation and molding plant

1. Vibrating sand falling machine 2. Vibrating conveyor 3. Elevator 4. Sand bin

1. Vibrating sand falling machine 2. Vibrating conveyor 3. Elevator 4. Sand bin

5. Vibrating feeder 6. Vibrating crusher 7. Elevator 8. Magnetic separator

9. Reclaimer 10. Elevator 11. Sand bin 12. Fluidized-bed

13. Elevator 14. Sand bin 15. Sand mixer

Resin sand regeneration line

The resin sand is a molding and core making technology which the mould and core sand will be self-harded in some time in the flask when added in certain amount glue. At present, the foundry usually

applies furan resin sand, ester-hardening alkaline phenolic resin sand and pep-set resin sand. The great characteristic is that under the room temperature the resin sand can be self-harded. The self-harded rate and hardness is related to the room temperature, environment humidity.

It fits the single piece, small batch, various medium and large scale casting’s mould and core, widely

used in the tool, general, heavy, shipbuilding, locomotive, motorbike.

The roll-over mold lifting machine

Working principle

1.Resin on the used sand is removed by well-engineered combustion technology

2.This crushed and segregated sand is heated to burn the resin and the sand is recycled again.

3.Heat generated from resin burning can be recovered to preheat the sand as well as combustion air

Features

1.Optimized secondary fuel consumption(LPG) depending on the properties of resin

2.Low Operating Cost

3.Fully automatic plant with instrumentation for process control

4.safe and reliable operation

5.smooth and consistent operation in spite of variations in resin content

6.Tailor made capacities available

The reason Why you choose Shengmei

With our manufacturing and customer-servicing experience we are a reliable, well-established company and our products are dependable, functional, safe and aesthetically pleasing.

Shengmei V process molding line plant is your best choice

After-Sales Service

Equipment Installation, Commission, Training, Warranty and After sales Services

1. Installation

A. Under the following conditions are satisfied, the seller’s installation and construction team will start equipment

installation and commissioning for a period of four weeks;

a. Infrastructure installation, civil construction, maintenance have been completed, and meet the installation requirements;

b. The cooling water pipes are connected in place. Pressure and flow meets the seller’s demand;

2. Commission

When commission, what should the two parties do?

The supplier’s responsibility

a.the supplier should send one or two engineer to the buyer’s plant;

b.The supplier should provide the materials needed for applying for visa;

The buyer’s responsibility

a. The buyer should apply for visa for engineer(Or the seller apply, but the buyer pay for the fee)b.The buyer should provide food and room for engineer during installation,commission and training at the buy’s plant;

c. The buyer should be responsible for the following:

|

No. |

Item |

|

1 |

Round-trip ticket from China to the buyer’s country |

|

2 |

Round-trip ticket from Qingdao to Beijing |

|

3 |

Rooms and meals in Beijing |

|

4 |

Health Certificate |

|

5 |

Salary of Commission(100USD/day)after arriving the buyer’s plant |

Notice: The expense needed for installation,commission and training should be paid separately.

3. Training

The training will be run through the entire process of equipment installation and commissioning, and after normal operation, the supplier will provide the training, proper and safe methods of operation and personal protection knowledge to the operators;

4. Warranty

The seller guarantees that the quality guarantee period is 12 months in the condition of equipment and materials without problems;

This 12-month period counts as the earlier one of the following two time points:

a. It should account at the date of signing the final acceptance of goods or six month after the goods at the buyer’s plant;

b. If the deb ing is caused by the seller, the warranty period will extend its considerable time;

Packaging & Shipping

Company Information

Member Information

| Qingdao Shengmei Machinery Co., ltd. | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15712768581 |

| Contact: | Sandy Xue (internation trade ) |

| Last Online: | 16 Sep, 2017 |

Related Products of this Company

-

Vacuum process sand box/flask/foundry

-

lost foam process casting foundry

-

vacuum process casting and molding line

-

lost foam casting foundry machine for

-

mobile two arm furan resin sand mixing

-

No Image

Resin coated sand casting process

-

sandry made resin sand S89 fluidized bed

-

China resin-bonded sand casting

-

good after-sale service lost foam

-

S20 series spheroidal bowl type resin