| Model: | CWVC-5S |

|---|---|

| Brand: | Chuangwei |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | Laser Pcba Cutting , Fpc Laser Depaneling , UV Laser cut for Pcb |

| Price: |

-

|

| Min. Order: | 1 Set |

Product Description

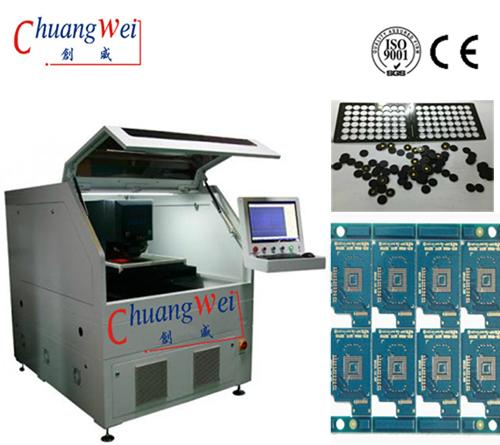

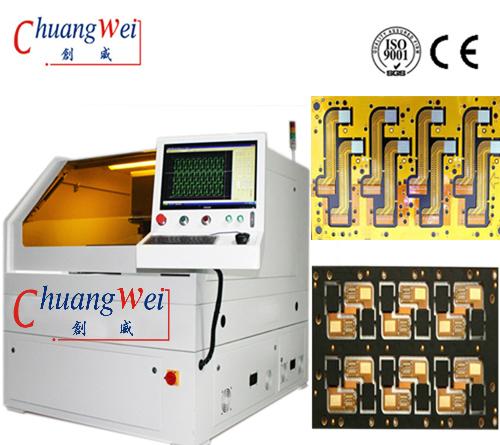

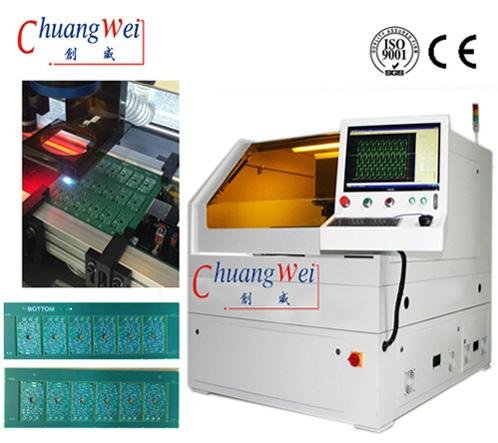

Fpc Depaneling,Fpc Cutting,PCB Cutter,CWVC-5S Detailed Product Description:

|

Product Name: |

Laser Pcb Separator |

Super: |

Low Power Consumption. |

|

Laser: |

12/15/17W |

Laser Brand: |

Optowave |

|

Power: |

220V 380v |

Warranty: |

1 Year |

Cutting Pcb with Laser PCB Depanelization,CWVC-5S Specification:

|

Laser |

Q-Switched diode-pumped all solid-state UV laser |

|

Laser Wavelength |

355nm |

|

Laser Power |

10W/12W/15W/17W@30KHz |

|

Positioning Precision of Worktable of Linear Motor |

±2μm |

|

Repetition Precision of Worktable of Linear Motor |

±1μm |

|

Effective Working Field |

460mmX460mm(Customizable) |

|

Laser Scanning Speed |

2500mm/s (max) |

|

Galvanometer Working Field Per One Process |

40mmх40mm |

Video of Fpc Depanelin with UV Laser,CWVC-5S

Challenges of Depaneling using Routing/Die Cutting/Dicing Saws

· Damages and fractures to substrates and circuits due to mechanical stress

· Damages to PCB due to accumulated debris

· Constant need for new bits, custom dies, and blades

· Lack of versatility – each new application requires ordering of custom tools, blades, and dies

· Not good for high precision, multi-dimensional or complicated cuts

· Not useful PCB depaneling/singulation smaller boards

Lasers, on the other hand, are gaining control of the PCB depaneling/singulation market due to higher precision, lower stress on the parts, and higher throughput. Laser depaneling can be applied to a variety of applications with a simple change in settings. There is no bit or blade sharpening, lead time reordering dies and parts, or cracked/broken edges due to torque on the substrate. Application of lasers in PCB depaneling is dynamic and a non-contact process.

Advantages of Laser PCB depaneling/singulation

· No mechanical stress on substrates or circuits

· No tooling cost or consumables.

· Versatility – ability to change applications by simply changing settings

· Fiducial Recognition – more precise and clean cut

· Optical Recognition before PCB depaneling/singulation process begins.

· Ability to depanel virtually any substrate. (Rogers, FR4, ChemA, Teflon, ceramics, aluminum, brass, copper, etc)

· Extraordinary cut quality holding tolerances as small as < 50 microns.

· No design limitation – ability to cut virtually and size PCB board including complex contours and multidimensional boards

Working principle :

humidity sensor ( humidity and temperature signal ) → Microcomputer ( CPU Central Processing Unit ) → Heaters ( PTC heating module polymer material heating ) → Smart shape memory alloy ( alloy shape with temperature change ) → Balance spring ( general balance spring with alloy )

PCB Separator with UV Laser Cutting Application:

FPC and some relative materials;

FPC/PCB/ Rigid-Flex PCB cutting, Camera module cutting.

If you need the machine,please contact us:

Skype/Email: s5@smtfly.com

WhatsApp/Wechat: +86 136 8490 4990

| Payment Terms: | TT/LC |

|---|---|

Member Information

| ChangWei Electronic Equipment Manufactory | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13684904990 |

| Contact: | Bunny (Product Manager) |

| Last Online: | 08 Oct, 2021 |

Related Products of this Company

-

Printed Circuit Board Router Machine -

-

Stress-Free Pcb Depaneling of Assembled

US $1

-

UV Fpc Laser Cutting Machine-PCB Laser

-

Laser PCB Depanelers - PCB Depaneling

-

PCB/Flex Circuit Laser Depaneling -

-

PCB Cutting Machine - Printed Circuit

-

Router PCB Board-Precision PCB Cutting

-

Inline PCB Routing Equipment PCB Router