| Model: | YJLV62 |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Electronics & Electricity / Optical Fiber, Cable & Wire / Electric Wire & Cable |

| Label: | - |

| Price: |

-

|

| Min. Order: | 1000 pc |

Product Description

1. APPLICALBE STANDARDS

The cable which Beijing Huayuan offered shall be designed, manufactured and tested according to international standards as follows:

Quality Control Standard

ISO 9001

Quality Management Systems

ISO 14001

Environmental Management Systems

Component Material Standard

IEC 60228

Conductors of insulated cables

Cable Standard

IEC 60502-2

Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV)

Part 2:Cables for rated voltages from 6 kV (Um = 7,2 kV)

up to 30 kV (Um = 36 kV)

IEC 60811

Insulating and sheathing materials of electric

and optical cables - Common test methods

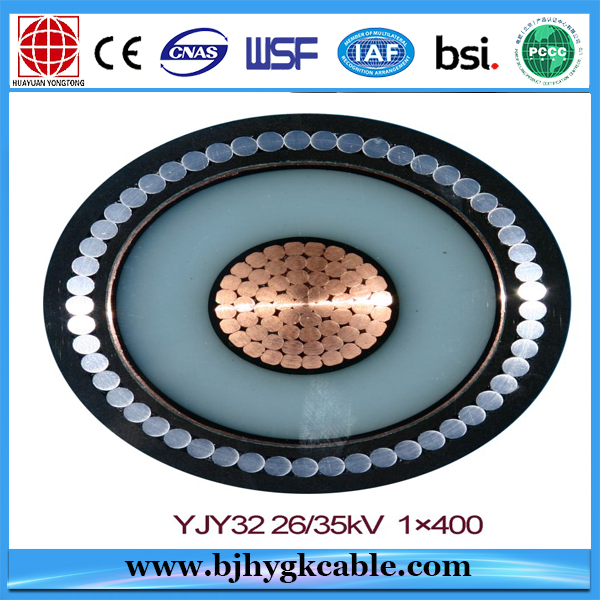

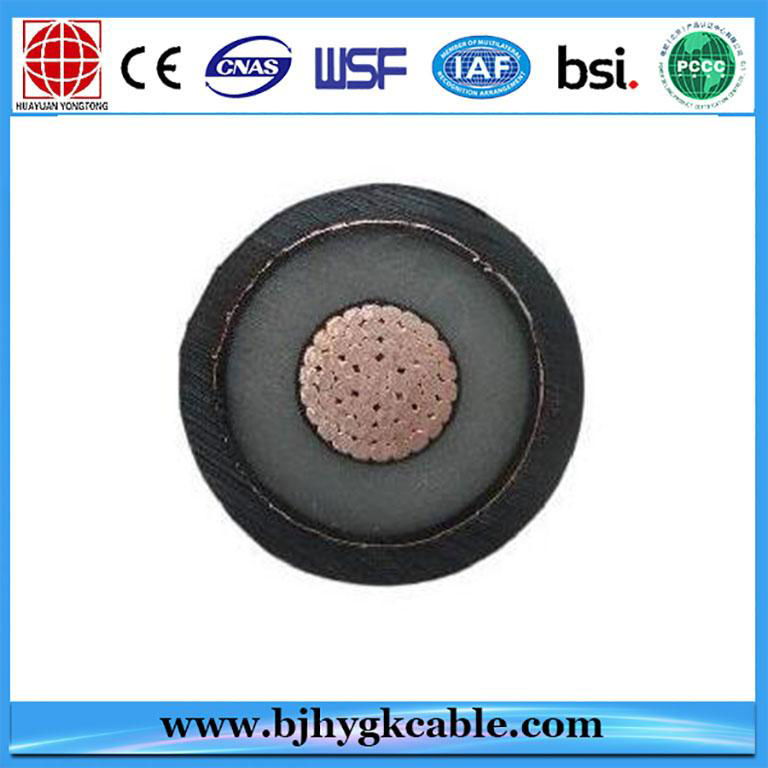

CABLES STRUCTURE for 1C*300 mm2 Cable

AL/XLPE/CTS/PVC/AWA/PVC 19/33(36) kV 1C* 300 mm2

Construction

Nominal Thickness(mm)

Nominal Diameter(mm)

1--- Conductor(Aluminum)

20.5

2----Conductor screen

0.8

22.1

3-- XLPE insulation

8.0

38.1

4--- Insulation screen

0.6

39.3

5--- Copper tape screen

0.12

39.7

6--- Warping tape

0.2

40.3

7--- PVC inner sheath

1.4

43.1

8--- Aluminum wire armour

2.5

48.1

9--- Warping tape

0.2

48.7

10---PVC Outer sheath

2.6

53.9

3.Guaranteed Technical Particulars

33 kV, 300 SQ.MM. SINGLE CORE XLPE CABLE

SN

Description

Unit

Offer

1

Name of Manufacturer

Beijing Huayuan

2

Country of origin

CHINA

3

voltage grade

kV

19/33

4

Max. conductor temperature

4.1

Continuous

90

4.2

Short Time

250(not exceed 5s)

5

CONDUCTOR

5.1

Material

Aluminum (Circular compact stranded ,Class B)

5.2

Size

mm2

300

5.3

Nos. & Diameter of wire in each Conductor (Before Stranding )

Nos./mm

37/3.28

6

SHIELDING ON INSULATION (Non Metallic )

6.1

Material

Semi-conductive XLPE compound

6.2

Thickness

mm

0.6(nominal)

7

INSULATION

7.1

Material

XLPE

7.2

Thickness

mm

8.0(nominal)

7.3

Calculated Dia Over insulation

mm

38.1(nominal)

8

INNER SHEATH

8.1

Material

PVC

8.2

Thickness

mm

1.4(nominal)

8.3

Extruded

Yes/No

YES

8.4

Calculated outside dia. over sheath

mm

43.1(nominal)

9

ARMOURING

9.1

Material

Aluminum wire

9.2

Size of Armour Wire

mm

2.5(nominal)

9.3

Calculated dia. over armour

mm

48.1(nominal)

10

OVERALL SHEATH

10.1

Material

PVC

10.2

Thickness

mm

2.6

11

Net weight of Cable

Kg/km

2990

12

CONTINUOUS CURRENT RATING FOR STANDARD IS CONDITION LAID DIRECT (Cable Solid Bonded)

Air temperature 40 C and , 1 circuit ,phase spacing 1 time cable outer diameter, trefoil formation, depth of laying 800 mm ,thermal resistivity of soil 1.0 k.m/W,soil temperature 25,pipeline inner/outer diameter 90/100mm.

12.1

In Ground

A

512

12.2

In Duct

A

475

12.3

In Air

A

553

13

Short Time Current rating for 1 Sec

kA

28.2( Of conductor)

14

DC Resistance at 20

Ohm/km

0.1 (of conductor)

15

ELECTRICAL PARAMETERS AT MAX. OPERATING TEMPERATURE

15.1

AC Resistance

Ohm/km

0.129

15.2

Reactance at 50 c/s

Ohm/km

0.162

15.3

Impedance

Ohm/km

0.139

15.4

Capacitance

mF/km

0.000245

16

Recommended minimum bending radius x Overall Dia.

mm

810

17

Standard Specification to Which Cable manufacture and tested

IEC 60502 IEC 60228 IEC 60811

4.TEST REQUIREMENTS FOR MV Power Cables

The cable testing shall be conducted in accordance with applicable standard of 33 kV Power Cables. The following test items shall be carried out in accordance with relevant IEC60502-2 standards.

No.

Test item

Routine tests

1

measurement of the electrical resistance of conductors

2

Partial discharge test

3

Voltage test

Sample tests

1

conductor examination

2

check of dimensions

3

Voltage test for 4 h

4

Hot set test for XLPE insulation

5. PACKING PARTICULARS FOR 33kV Power Cables

The cables shall be wound on steel-wooden drums. The indelible marking shall be printed on the surface of drum flange in accordance with customer requirements.

Cable Type

Drum length(m)

Drum Dimensions (mm)

d1

d2

L2

L1

AL/XLPE/CTS/PVC/AWA/PVC-19/33kV-

1C*300mm2

700

2200

1100

940

1100

Note: The value [D" shall not contain the dimension of sealing plates.

Factory and Equipment

Package:

Honor:

http://www.bjhygkcable.com

Member Information

| Beijing Huayuan Gaoke Cable Co.,Ltd. | |

|---|---|

| Country/Region: | Beijing - China |

| Business Nature: | Trading Company |

| Phone: | 18911108016 |

| Contact: | Crazy Zhang (CEO) |

| Last Online: | 02 Oct, 2017 |

Related Products of this Company

-

Medium Voltage 33kv XLPE Insulated Power

-

Branch Cable With 3 Outlet Male Plug CSA

-

1KV Copper Conductor Material and

-

0.6/1kv 4x120mm2 XLPE Insulated, PVC

-

MIDDLE VOLTAGE ELECTRIC CABLE COPPER

-

1KV Copper Conductor XLPE Insulation PVC

-

24KV 3*240sqmm Aluminum Conductor XLPE

-

Low Voltage Copper Cable Cu/XLPE/PVC

-

6/10kV XLPE Medium Voltage Power Cable