| Model: | QT-40 |

|---|---|

| Brand: | QT |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Energy Saving |

| Label: | Alu. profile puller , biomass burner , biomass pelletburner |

| Price: |

¥24000

/ pc

|

| Min. Order: | 1 pc |

Product Description

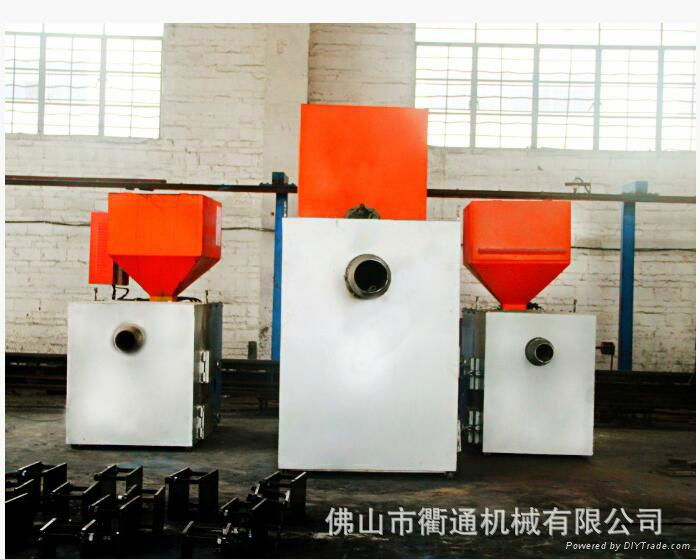

Product introduction:

As the case that the traditional fossil fuel is going to be exhaust and the environment pollution is becoming more and more serious, all the countries in the world are actively seeking and developing more renewable energy. Biomass fuel not only can replace traditional fossil fuel, but also can reduce carbon emissions.More and more countries round the world are replacing fossil fuel to renewable bio fuels. However, because of lag of bio fuel equipment in the market, bio fuels have not been vigorously developing. Until a direct-burning type burning machine launched on the market in recent years, bio fuels have been widely promoted.

However, there are many defects in the direct-burning type burning machine. Such as the fuel burning temperature in the combustion chamber is very high, even higher than of the jet flames. It will make the temperature and the internal pressure of combustion chamber higher and that lead to the life of combustion burner become shorter. Also it would projet out a lot of unburned ashes in the jet flames.

To step out the defects of the direct-burning type burning machine, we developed a biomass gasification combustion machine. Which the working principle as following:

Put the biomass fuel in the combustion chamber, then gasifying the biomass fuel with medium temperature, then spew combustible gas and add oxygen to make it burning at high temperature only at the jet flames. This new development has a lot of advantages such as medium temperature in the combustion chamber, low pressure, high temperature flames without ashes and more fuel saving.

Features:

1.Low carbon emissions, clean environment.

2.High combustion rate, save fuel. The machine all adopts computer automatic control, and can adjust parameters through temperature sensing to keep warm and save fuel.

3.Long service life. The chamber is made of stainless steel material. The use of air-cooled technology make the tank temperature control at 400-600℃, and protect the liner at the maximum.

4.Easy operation. For the first time, manual ignition is required. Next time, all operations can be displayed on the control panel.

Principle: feeder push fuel into the combustion chamber, medium temperature gasification blower heating the biomass fuel to gasification temperature. Medium temperature gasification flame jetted via a flame outlet. At this time, medium temperature gasification flame mix with hyperbaric oxygen jetted by an air blower then produce high temperature flame to heat workplace. The air blower also use the air as cooling air for the combustion chamber.

Structure:

1.The combustion chamber: two layers of stainless steel is composed of heat insulation type combustion chamber and heat preservation cotton keep heat preservation and insulation. The outer was protected by steel plate.

2.Feeding mechanism: feeding tube, feed screw, feeding power motor, and storage box.

3.Oxygen supply mechanism: a medium temperature gasification fan, a cooling plus oxygen extension.

4.Control mechanism: three frequency converters, PLC, temperature control module, HMI and other electrical components of the fully computerize control box.

Member Information

| Foshan City Qu Tong Machinery Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13794600350 |

| Contact: | Daniel Huang (Vice general manager) |

| Last Online: | 26 Oct, 2017 |