| Model: | TU-004 |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Industrial Supplies / Leather Processs Machinery |

| Label: | - |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

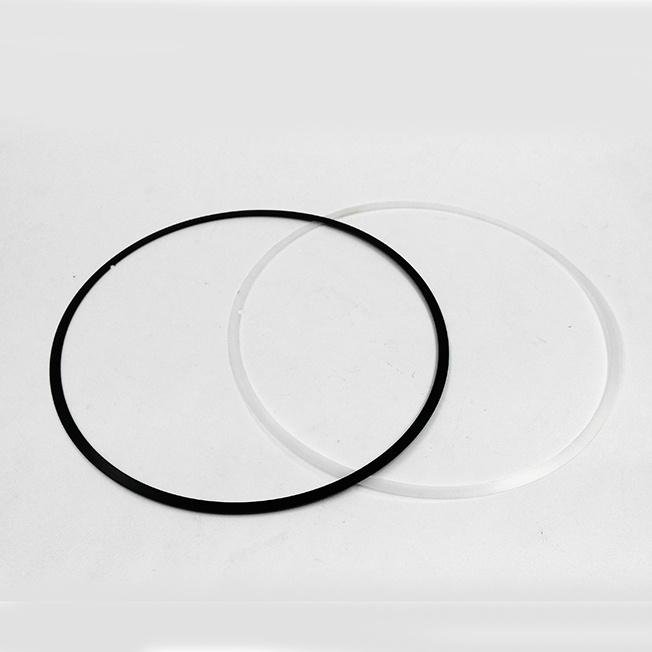

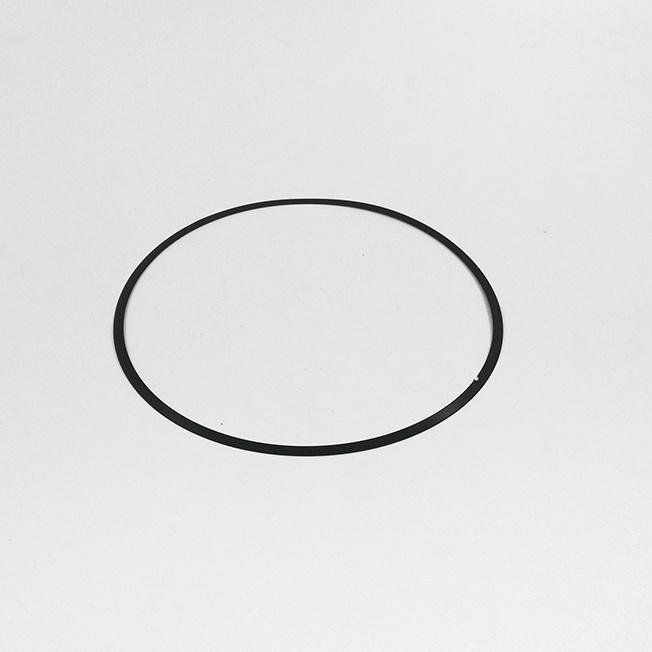

Ultra-thin CNC Turning Plastic Parts

In order to obtain Ultra-thin CNC turning plastic parts, ( Thickness 0.23 mm ). We use POM as the material to be processed. To ensure the insulation of the CNC turning parts. Ultra-thin CNC turning plastic parts are widely used in slip rings.

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of machining performance, machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts, as well as six lathe. Machining size of the largest diameter can reach 860mm, a single product the thinnest 0.23mm CNC turnining and CNC milling machining materials are:

copper / bronze / H62,

Titanium / TC4

Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6082.

Stainless steel: 1.4305,1.4301, 316 ,

Steel: Q235, 45 #, A3, 718H, S136, SKD11

Plastic: POM, Teflon, PA, ( PA66 ) PC, PMMA.

Product surface treatment: anodize ( clear, black, blue, yellow, can also customize a variety of colors), sandblasting, spraying, passivation, laser engraving LOGO, silk screen LOGO. Our CNC machining turning parts include: Auto Parts, Robot Parts, bushings, Shift knobs, Motorcycle Parts, Toy Parts, Knobs, Pulleys, shafts, hubs, Drone parts, flywheels, etc..

From the procurement of raw materials to CNC machining parts shipments, we have established a complete set of quality control system. The whole process of operating workers by SOP operations, IPQC products for each machining steps to detect, make sure the product meets the requirements before proceeding to the next CNC machining Turning. And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report. Engineering and technical personnel on a regular basis for machining and maintenance settings, timely update machining tool. Our inspection tools are: Digital caliper, Micrometer Calipers, height gauge, Profile projector...Tolerances can be measured +/-0.01mm and 0.001mm.

We focus on short-term delivery, commitment to provide samples a week. For a simple CNC Turning parts, complete the sample in 3 days. The factory provides 2 ~ 3 sets of CNC Turning Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day. In order to meet these services, we also have a qualified supplier base, so that we can provide products from the surface to the parts LOGO mark the integrity of the quality of CNC turning services.

http://www.bldcncmachining.com

Member Information

| Buildre Group Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Trading Company |

| Phone: | 13928436173 |

| Contact: | Sun (CEO) |

| Last Online: | 31 Oct, 2017 |

Related Products of this Company

-

Turning Machining Blue Delrin Parts

-

Silver Plated Brass Parts for Slip Ring

-

Turning Acrylic CNC Parts

-

Milling Precision 6061 Thin Aluminum

-

Precision CNC Machining Aluminum

-

CNC Milling Machining for Jewelry Boxes

-

Machining Aluminum Battery Compartment

-

Laser Engraving on Anodized Aluminum

-

Machining Aluminum Parts 6061-T6

-

CNC Machining Turning Parts for Medical